Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2022.02

55/175

Technical description

4.21 Selecting lubricating oil for Sabroe screw compressors

To ensure the compressor unit a long service life with safe and reliable operation, it is important

to use an oil type recommended by Johnson Controls Denmark. Please refer to Sabroe oil rec-

ommendation where various oil types are listed in a table including oil brand, oil code and part

numbers.

Warning!

Only use oil recommended by Johnson Controls Denmark when first charging the plant and

when recharging. Mixing different oil types can cause irreversible damage.

4.22 Oil charge

See subsection 11.13 Oil charge.

4.23 Heating rod element for oil heating, pos. 30

In order to keep the lubricating oil in the compressor warm during a standstill period, the oil re-

ceiver has one or two built-in heating rods. Before start-up, the heating rods must have been

activated for six to eight hours to ensure that there is only a minimum of refrigerant in the oil.

When containing a lot of refrigerant, the oil will lose its lubricating property and tend to foam,

which can cause shutdown by the level switch.

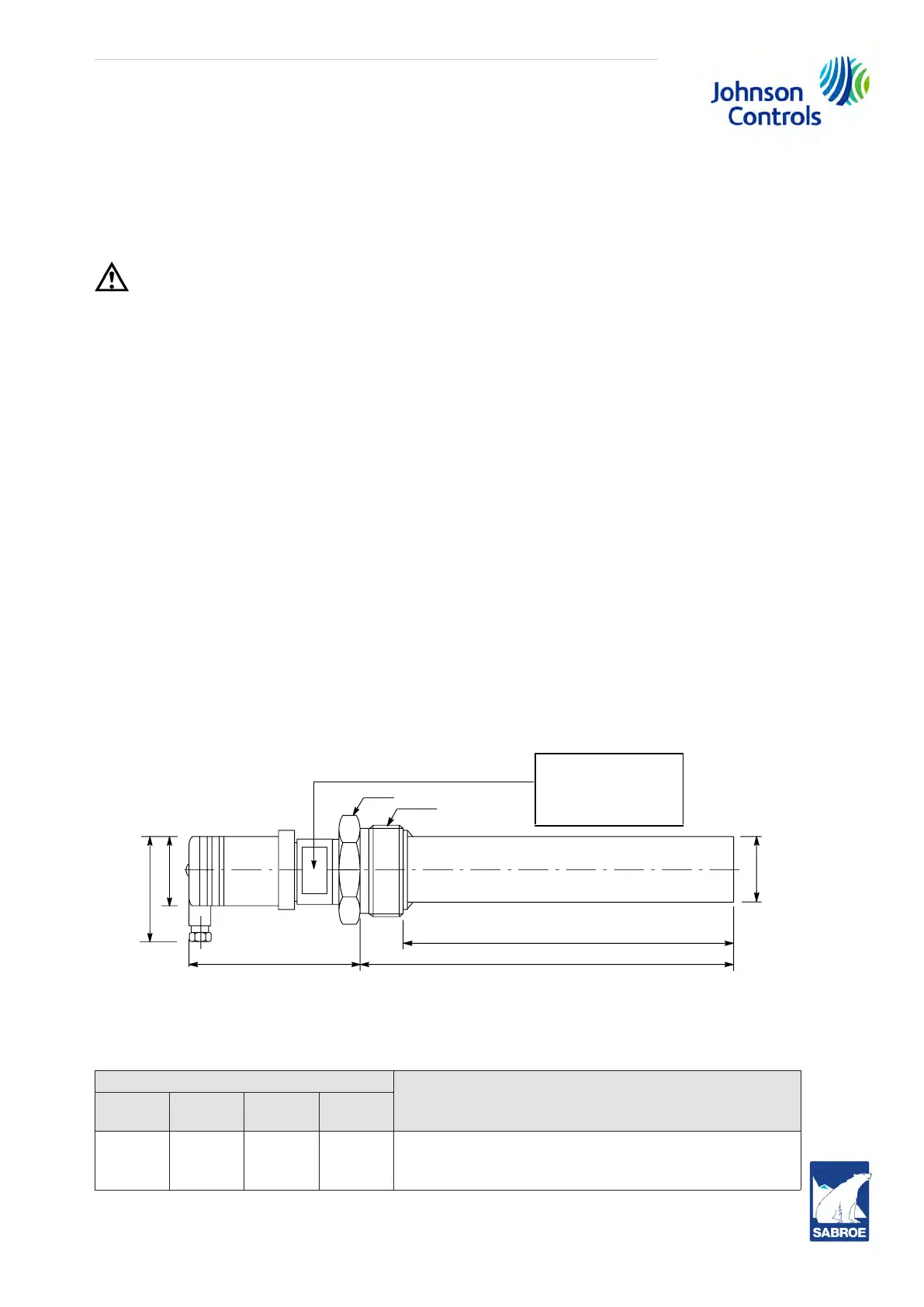

As illustrated in Fig. 30, the direct heating rod consists of an electric heating element incorpo-

rated in a pipe with a diameter of 30 mm. The entire heating cartridge is screwed on tightly at

the G 1 1/4" thread. It is available in ATEX execution.

Note: The heating rod must not be energised if the oil level in the receiver is below the mini-

mum mark in the sight glass, and it should generally be switched off during compressor

operation.

Fig. 30: Heating rod, type A

Heating rods

Used for:

Power

Watt

Voltage

V

L1

mm

L2

mm

460

460

460

250

230

115

158 175 SAB 120/151/193/233/283/355

80L2

L1

NV50

G 1 ¼

30

50

M

arking: Prod. no.

Watt

Volt

Manu. date

ø 30

Loading...

Loading...