Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2022.02

59/175

Technical description

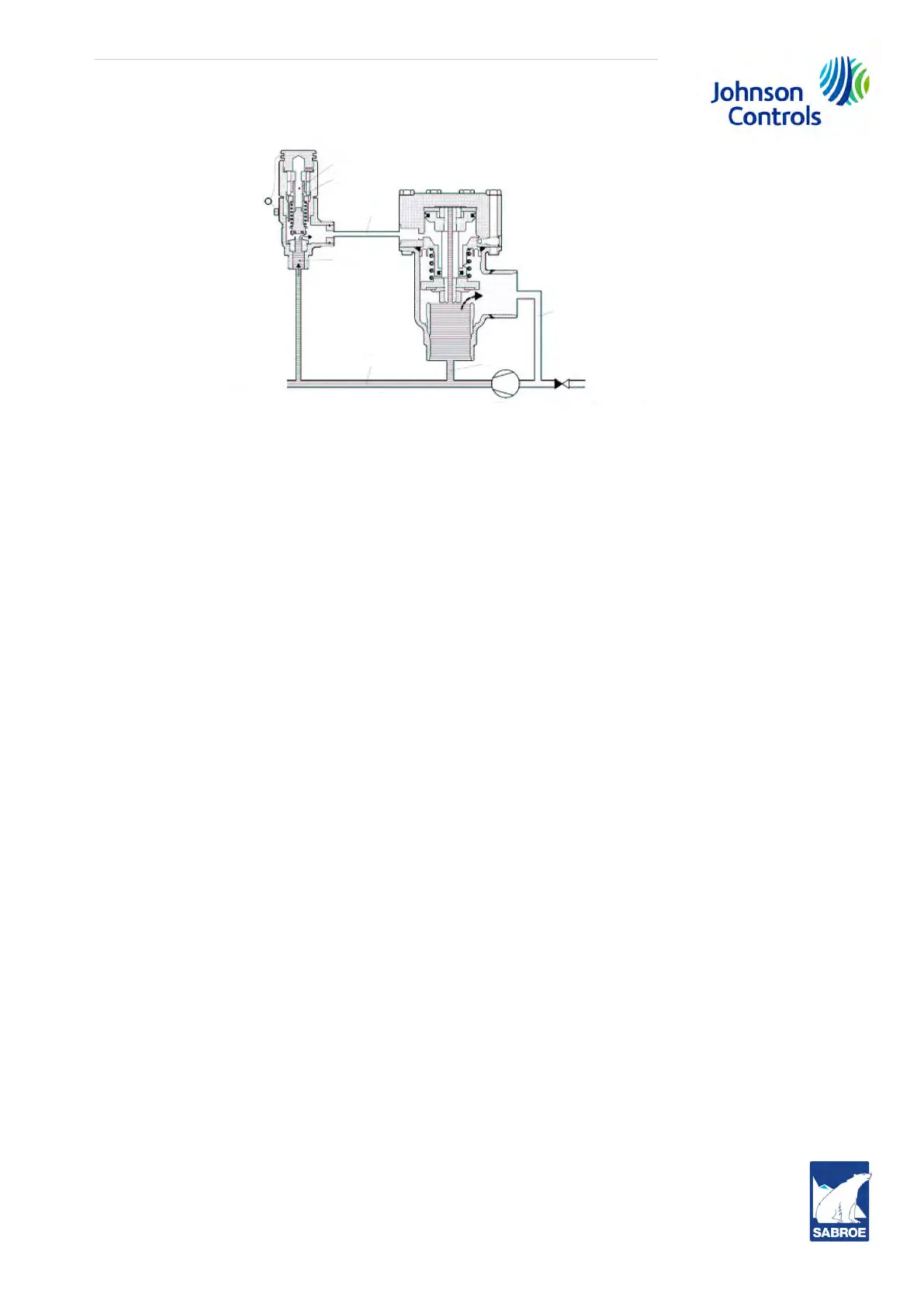

Fig. 34: System with open valve

4.27 Oil cooling system and general piping layout

General:

Min. oil temperature before start-up: 4°C (+40°F)

Min. oil temperature in running condition: 20°C (+68°F)

Liquid injection oil cooling: The compressor oil is cooled by direct contact with the refriger-

ant injected through an optimised port location prior to the compressor discharge. Liquid feed

arrangements include isolation valves, strainer, solenoid valve, sight glass, a thermal expan-

sion temperature control valve and a pressure differential control valve. The temperature con-

trol valve will maintain the temperature of the oil returning to the compressor between 54.4°C

[130°F] and 76.7°C [170°F].

Water-cooled oil cooling: The optional water-cooled oil cooler is either a plate and shell de-

sign (Vahterus) with oil on the plate side or a plate type oil cooler (AlfaNova). The coolers are

designed for design pressure 28 bar on both sides. The oil temperature is maintained between

50°C [120°F] and 60°C [140°F] for ammonia and halocarbons with a thermally controlled valve.

The oil cooler is mounted on the unit with the oil piping connected. Water connections and con-

trols are field installed.

Thermosyphon oil cooling: The optional thermosyphon cooler is a plate and shell design

(Vahterus) or a plate type oil cooler (AlfaNova). It is designed for design pressure 28 bar on the

shell side and 28 bar on the plate side. The oil coolers are mounted on the unit with the oil pip-

ing connected. Refrigerant connections and controls are field installed. The oil temperature is

maintained between 50°C [120°F] and 60°C [140°F].

4.28 Liquid injection oil cooling

High-stage compressor units may be supplied with single-port (low Vi) or dual-port (low Vi and

high Vi) liquid injection oil cooling. Single port will be furnished for low compression ratio opera-

tion and dual port for high compression ratio operation. Booster compressor units use single-

port liquid injection oil cooling due to the typically lower compression ratios.

The control system on high-stage units with dual-port liquid injection oil cooling automatically

switches the liquid refrigerant supply to the high port when the compressor is operating at high-

er compression ratios (above 3.5 Vi) for best efficiency.

Where low compression ratios are anticipated, thermosyphon or water-cooled oil cooling

should be used.

Oil separator, condenserCondensing pressure

Compressor

Evaporating

pr

essure

P 0

1

P 2 ”

P 1

P 1

P 1

P 2

Loading...

Loading...