Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2022.02

61/175

Technical description

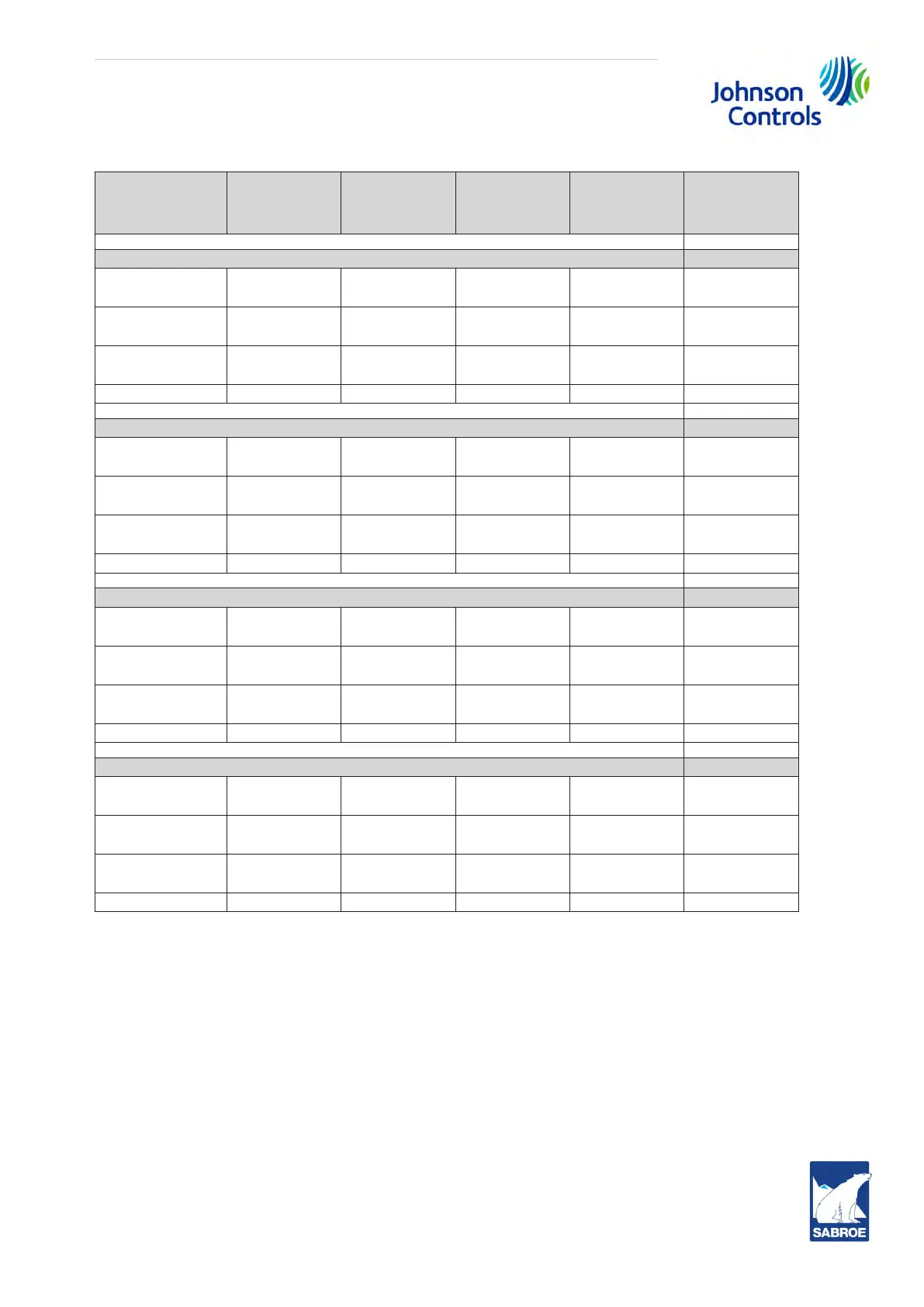

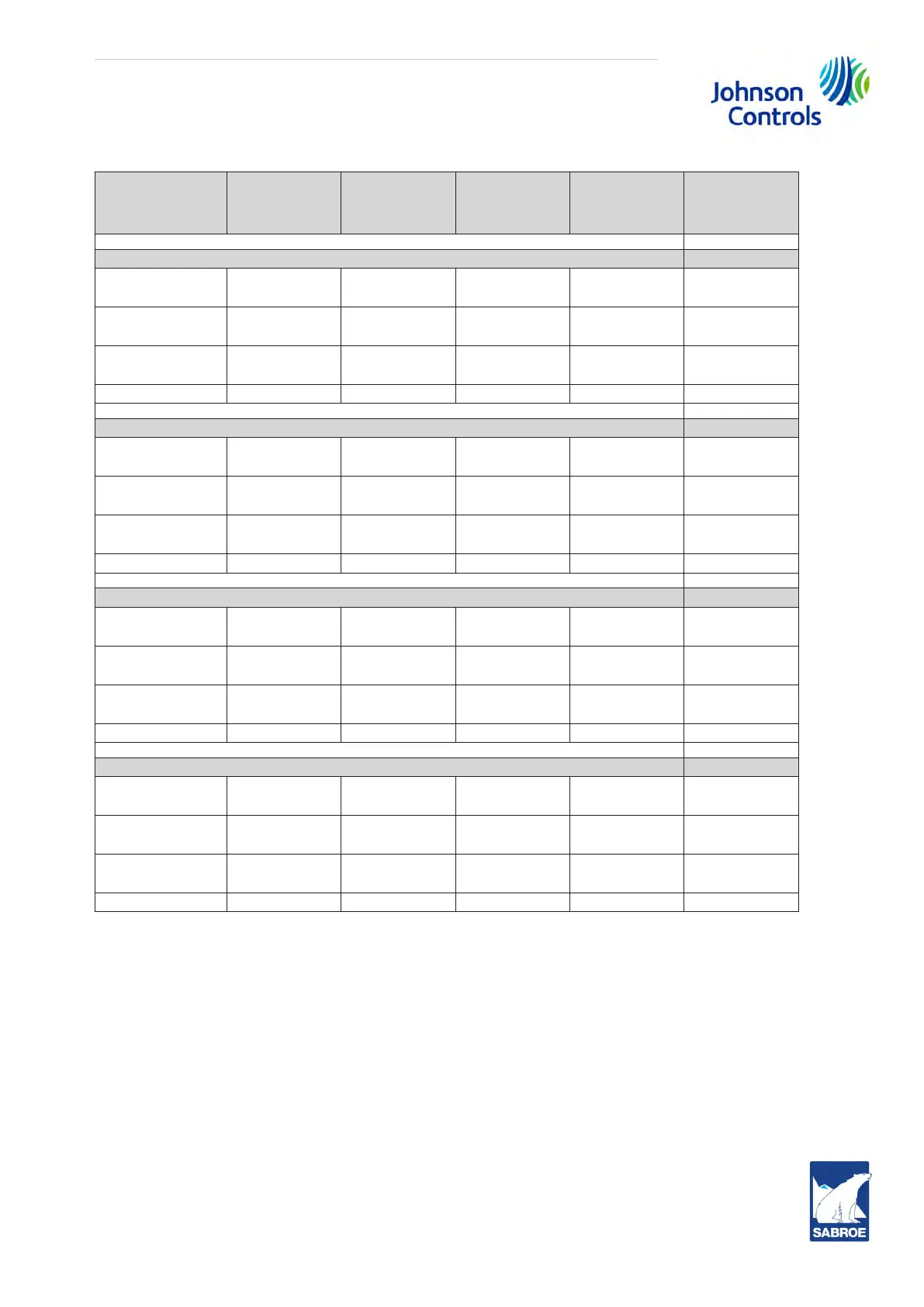

Unit

Model

Piping

line size

Pound

per min.

per 5 min.

Kg per min.

per 5 min.

Liquid

volume

cu ft

Liquid

volume

liter

R717 HS*

SAB 193 S and

L

3

/

4

75.5 34.2 2.1 59.4

SAB 233 S,

L and E

1 151.0 68.5 4.1 116.0

SAB 283 S,

L and E

1

1

/

4

219.5 99.6 6.0 169.8

SAB 283 X 1

1

/

4

300.0 136.2 8.2 232.0

R717 Booster*

SAB 193 S and

L

3

/

8

13.5 6.1 0.4 11.3

SAB 233 S,

L and E

1

/

2

25.5 11.5 0.7 19.8

SAB 283 S,

L and E

1

/

2

37.0 16.7 1.0 28.3

SAB 283 X

3

/

4

49.5 22.4 1.3 36.7

R507 HS*

SAB 193 S and

L

3

/

4

250.5 113.7 4.0 113.2

SAB 233 S,

L and E

1 500.5 227.2 8.1 229.2

SAB 283 S,

L and E

1

1

/

4

726.5 329.8 11.7 331.1

SAB 283 X 1

1

/

4

994.0 451.2 16.0 452.8

R507 Booster*

SAB 193 S and

L

3

/

8

41.5 18.8 0.7 19.8

SAB 233 S,

L and E

1

/

2

72.5 32.9 1.2 33.9

SAB 283 S,

L and E

1

/

2

106.5 48.3 1.7 48.1

SAB 283 X

3

/

4

146.0 65.8 2.3 65.0

Table 6: * Based on 100 ft liquid line. For longer runs, increase line size accordingly.

Conditions

Booster High-stage

Evaporating: -40°C [-40°F] Evaporating: -17.8°C [-17.8]

Condensing: +35°C [95°F] Condensing: +35°C [95°F].

Intermediate: -12.2°C [10°F]

4.29 Thermosyphon oil cooling

Thermosyphon oil coolers, like water (or glycol)-cooled oil coolers, eliminate the capacity and

power penalties associated with liquid injection oil cooling. Thermosyphon oil coolers have the

Loading...

Loading...