Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

98/175

008831 en 2022.02

Technical data

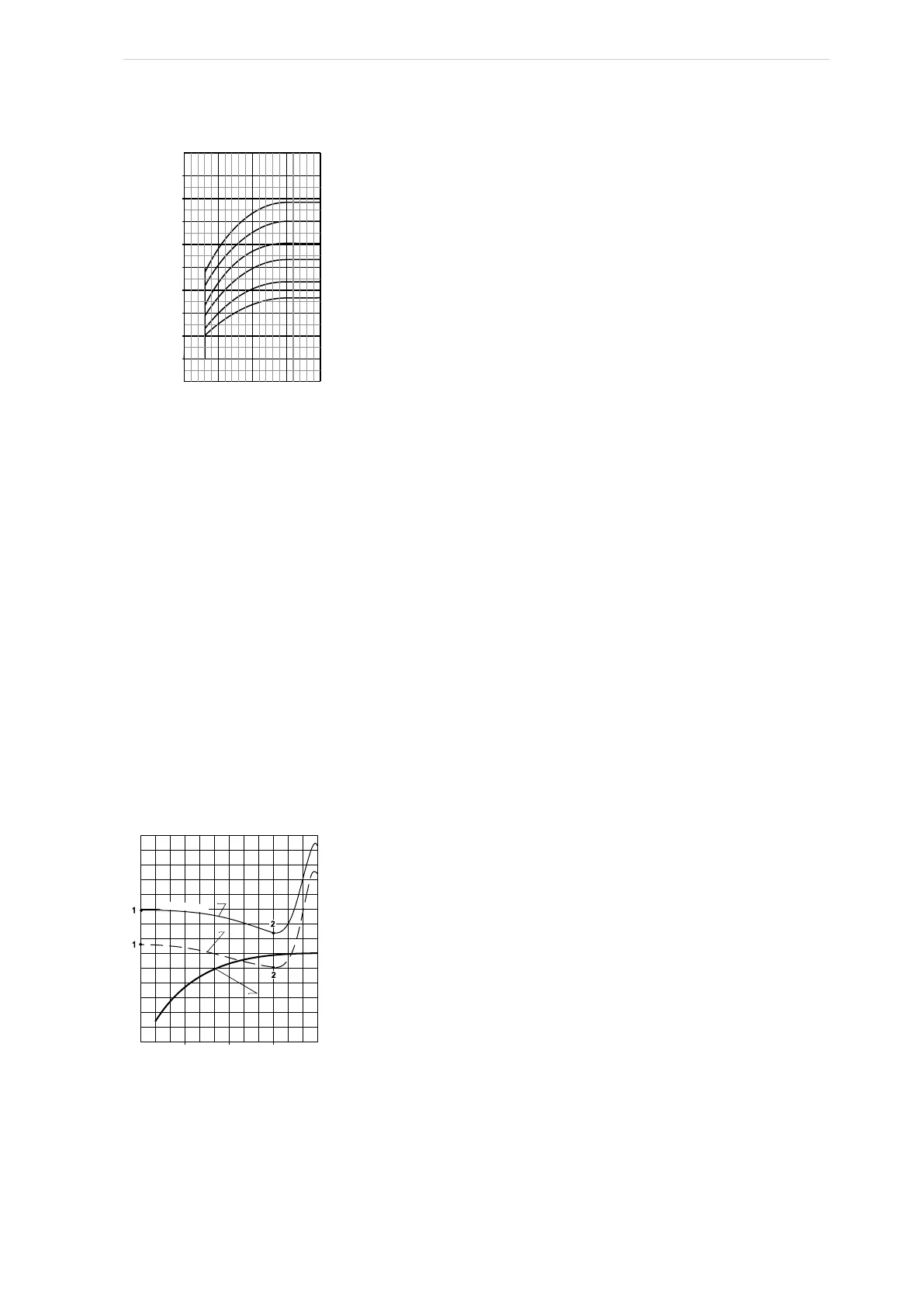

Fig. 69: Starting torque curves, booster

Starting torque for specific compressor

Multiply the starting torque value from high-stage or booster curves at 100% of normal run

speed by starting torque multiplier for appropriate compressor size.

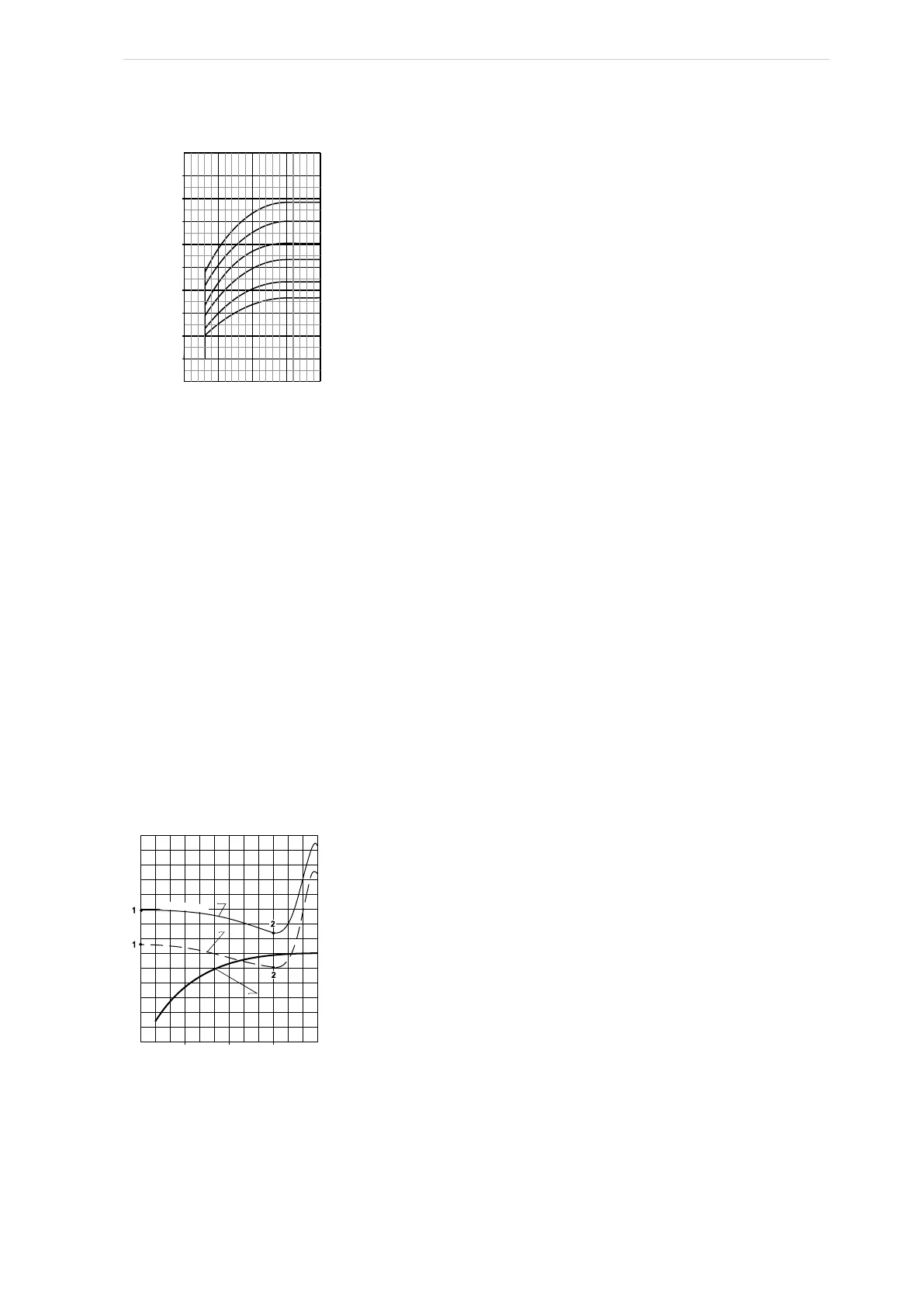

6.9 Motor/compressor torque

Ensure that the motor starting and minimum pull-up torque capabilities will exceed the com-

pressor requirements at the anticipated condition that will be experienced during normal

starting.

Note: Star-delta and auto transformer (reduced voltage) motor starting methods drastically ef-

fect the starting torque available from motors as indicated:

Across-the-line

100% torque

Auto transformer 25-64% torque

Star-delta 33% torque

Fig. 70: Motor/compressor torque

136

122

108

95

81

68

54

41

27

14

100

90

80

70

60

50

40

30

20

10

0

Nm

[Ft-lb]

50

100

75

Discharge pressure

0

25

55

45

35

25

15

10

3.8

3.1

2.4

1.7

1.0

0.7

[Psig]

Bar

S t a r t i n g t o r q u e

Percentage of normal run speed

Speed vs starting torque curve fully unloaded

Speed

25

50

75

100%

T or

que

M

otor B

Compressor

Motor A

M

otor A: Adequate to start the compressor

Motor B: Will not start the compressor

Loading...

Loading...