Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2022.02

97/175

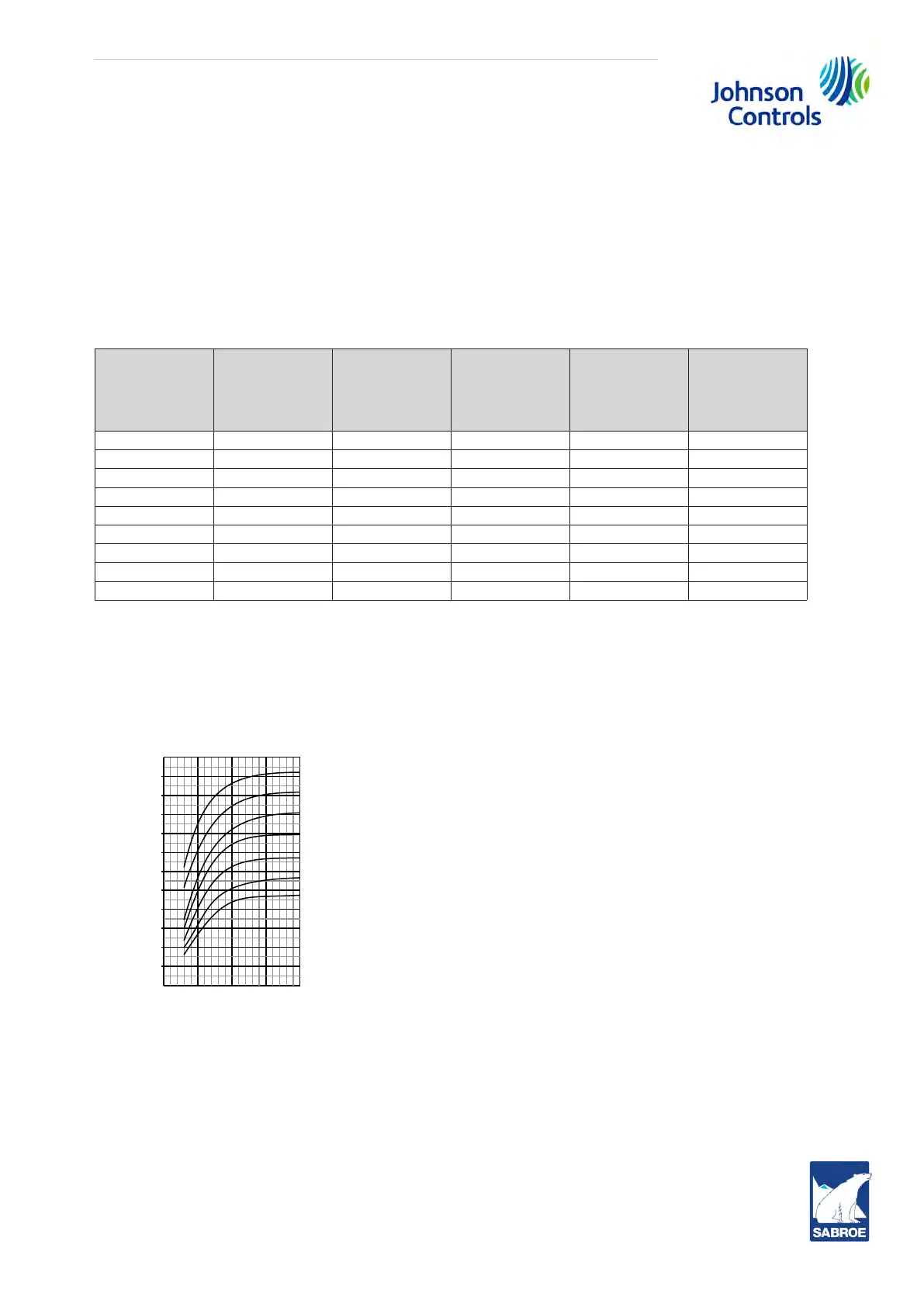

Technical data

6.8 Motor selection and starting torque

Motors must be sized adequately for all expected operating conditions as start-up, pull down

and load variations quite often require significantly more horsepower than nominal design.

Motor starting torque capacity must also be considered, especially when across-the-line start

is not used. Motor starting and pull-up torque must be at least 20% greater than compressor

requirements at maximum expected start-up conditions. See the torque data.

Note: Motor starting torque varies considerably from one manufacturer to another. Therefore,

make sure to obtain specific torque data for the motor used.

Unit

Starting

torque

(1)

multiplier

Breakaway

torque

(ft-lb)

Breakaway

torque

(Nm)

(2)(3)

Mass mo-

ment of iner-

tia

(lb-ft

2

)

(2)(3)

Mass mo-

ment of iner-

tia

(kg m

2

)

SAB 193 S 0.75 10 14 5.1 0.21

SAB 193 L 1.00 10 14 6.5 0.27

SAB 233 S 1.32 14 19 13 0.55

SAB 233 L 1.66 14 19 16 0.67

SAB 233 E 2.24 14 19 18 0.77

SAB 283 S 2.36 20 27 33 1.4

SAB 283 L 2.98 20 27 41 1.7

SAB 283 E 3.58 20 27 48 2.0

SAB 283 X 4.48 20 27 56 2.4

Table 23

1. High-stage or booster application.

2. Does not include coupling.

3. Inertia resolved to drive shaft.

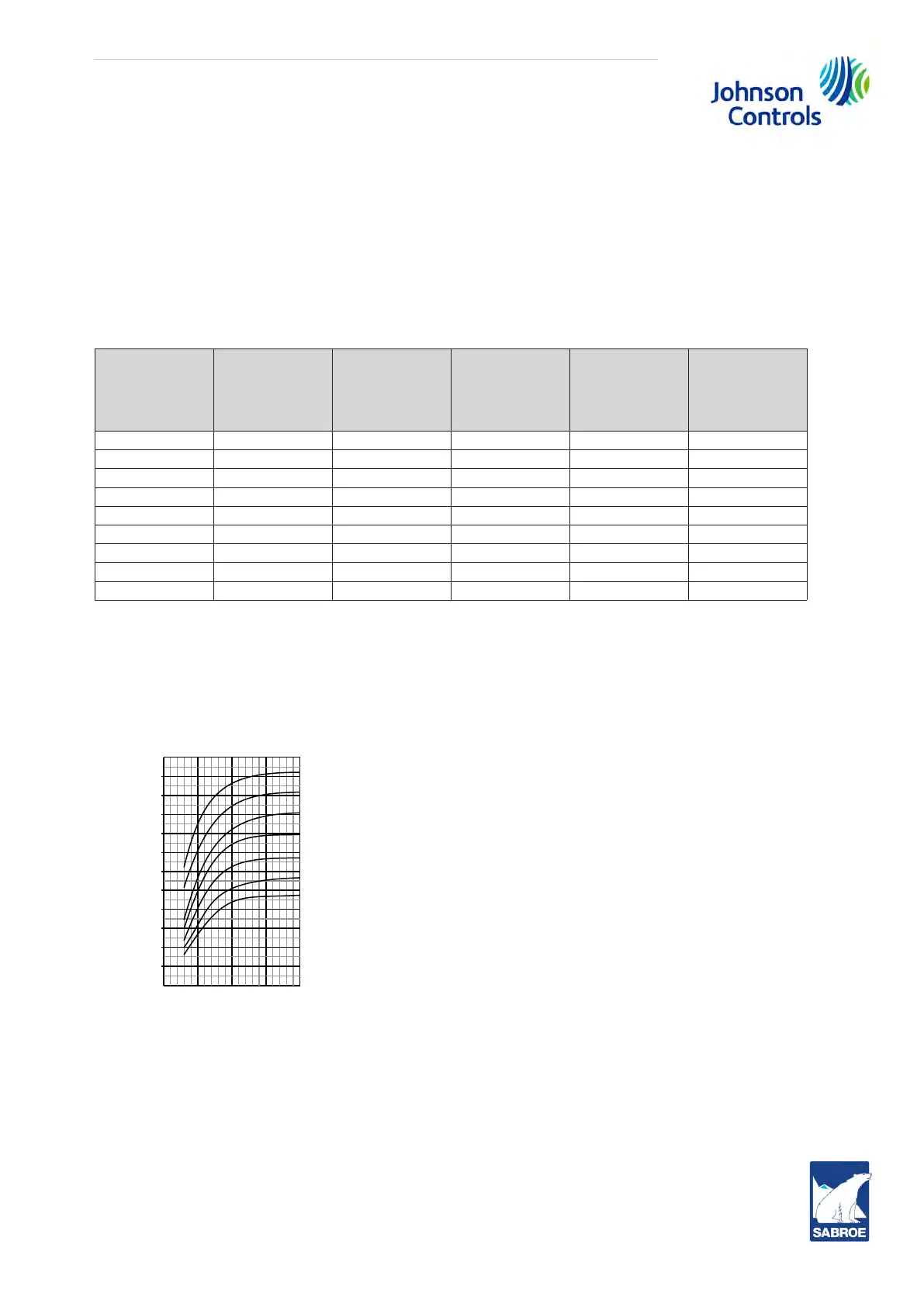

Fig. 68: Starting torque curves, high-stage

0

25

5075100

275

250

225

200

175

150

125

19

17

15.5

14

12

10

9

[Psig]

Bar

Starting torque

Speed vs starting torque curve fully unloaded

Percentage of normal run speed

Discharge pressure

40

60

80

100

120

140

160

180

200

220

240

260

280

[Ft-lb]

Nm

54

81

108

136

163

190

217

244

271

298

325

353

380

Loading...

Loading...