7 - 24

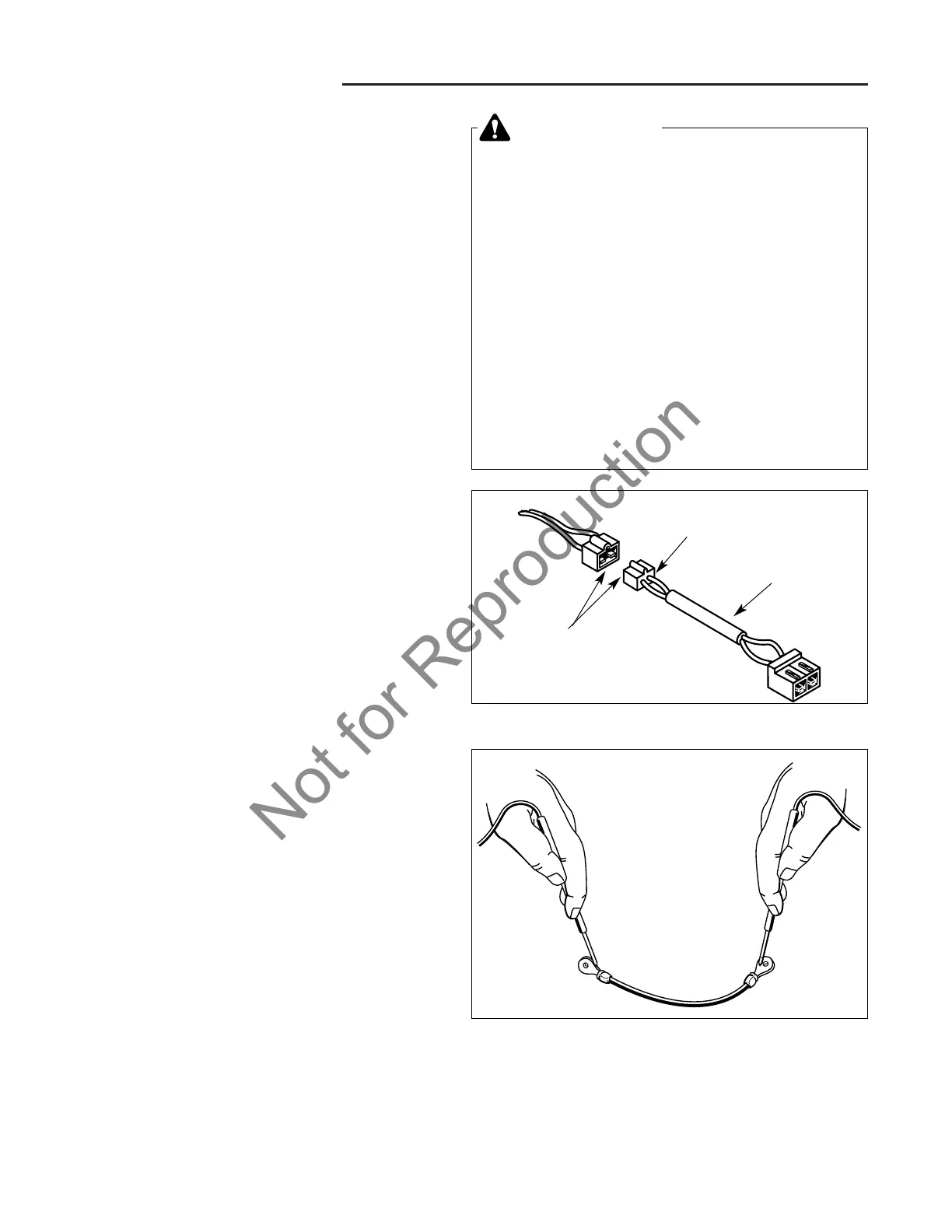

Figure 21. Testing Cable Continuity

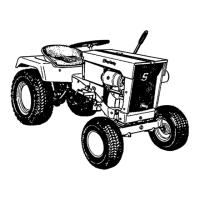

Figure 20. Typical Wire Harness

Check for

Loose Wires

Inspect

Insulation

Check for

Corrosion

7 Electrical System Service

Component Tests

COMPONENT TESTS

General

The following tests should be used in conjunction with

this sections troubleshooting flow charts to efficiently

troubleshoot common electrical problems; however, if a

specific component is suspect, these tests can be used

independently of the flow chart and of each other.

A. Check/Clean Wires and Connectors

1. Check all wires for cracked or worn insulation.

2. Check all connectors, terminals, and receptacles for

loose wires or corrosion (Figure 20). Refer to the

exploded view diagrams for wire harness locations.

B. Check/Clean Ground Cable

1. Disconnect and secure the negative battery cable

(see Section 6, COMMON SERVICE PROCE-

DURES).

2. Disconnect the other end of the negative battery

cable (ground cable) from the engine.

3. Clean the battery and cable terminals with a wire

brush until the metal is shiny.

4. Using a VOM set to Ohm, test the continuity of the

cable (Figure 21). The VOM should register no more

than 2-3 ohm.

5. Clean the negative battery post and engine ground

with a wire brush until the metal is shiny.

6. Reattach the negative cable to the engine block and

then the negative battery terminal.

WARNING

Before beginning any test,

ALWAYS:

• Disconnect the spark plug wire.

• Block the wheels.

IN MOST CASES:

• Engage the parking brake.

• Turn the PTO switch OFF.

• Turn the ignition switch OFF.

• Place the ground speed control lever in

NEUTRAL (Peerless models only).

If a test procedure requires a configuration other

than the one listed above, instructions will be pro-

vided in that specific procedure.

Always reset the tractor to the configuration listed

above unless told otherwise.

Loading...

Loading...