0020308118_05 Installation and maintenance instructions 47

Validity: VU 35CS/1-5 (N-GB) ecoTEC plus 635 OR VUW 30/40CS/1-5 (N-GB)

ecoTEC plus 840

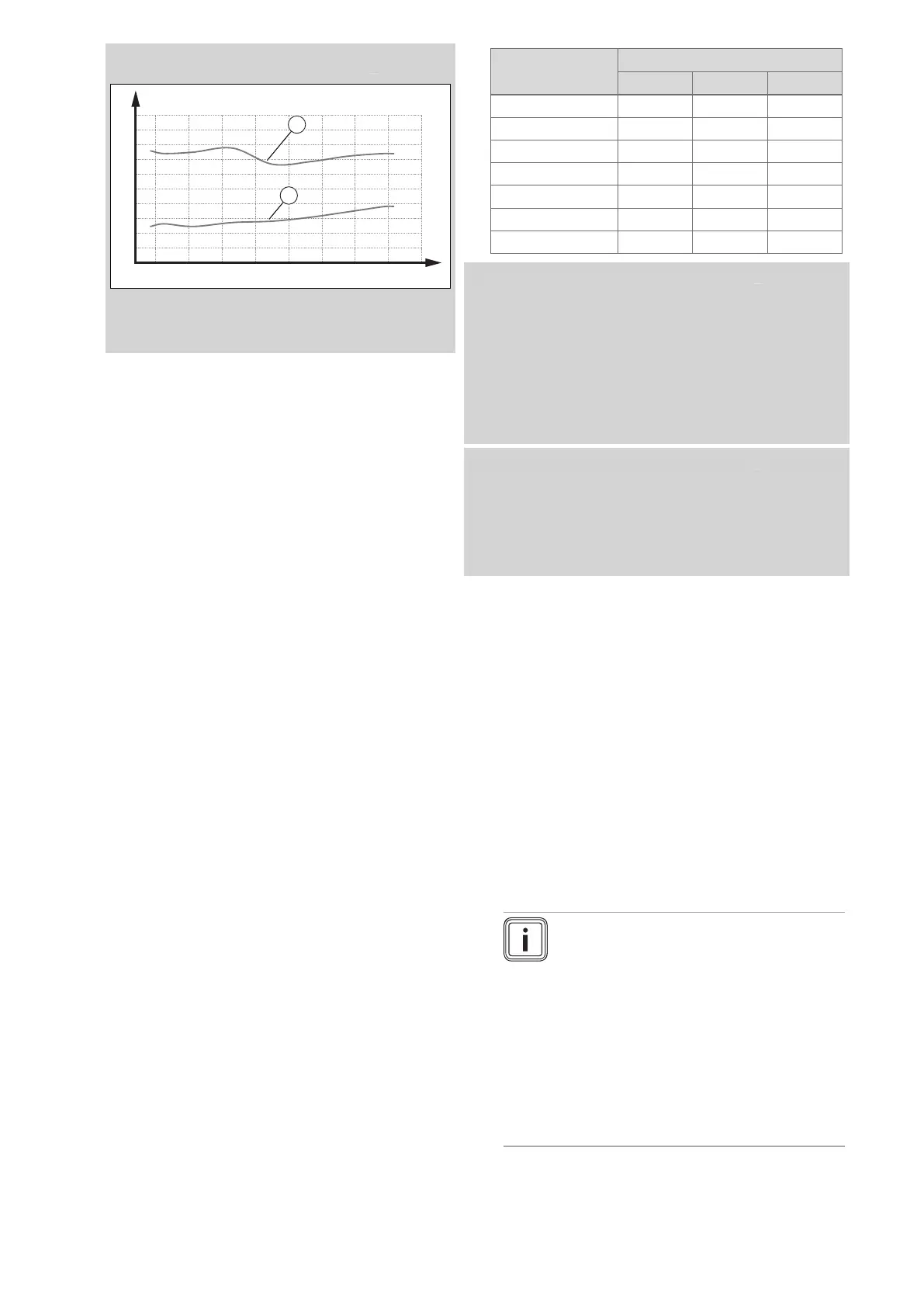

5 1015 2025 30354045

B

4

6

8

10

2

0

A

2

2

1

A O₂ content [vol%]

1 Max. O₂ content,

natural gas

B Heat input [kW]

2 Min. O₂ content,

natural gas

Result:

The value lies outside of the permitted range

▶ Check the total pipe length of the air/flue system;

see the set-up instructions for the air/flue system.

▶ Check the air/flue system for recirculation and

blockages. (→ Section 9.13.2)

▶ Measure the O₂ content at the flue gas analysis

point again and log the measured value in the

benchmark log in the appendix.

▶ If the O₂ content remains outside of the permissible

range, correct the gas-air ratio via D.158 and meas-

ure the O₂ content again at the flue gas analysis

point.

▶ If the O₂ content remains outside of the per-

missible range, replace the control electrode

(→ Section 13.7.14) and reset D.158 to the factory

setting.

▶ Measure the O₂ content at the flue gas analysis

point again and log the measured value.

▶ If the value is still outside of the permissible range,

do not start up the product and, instead, report this

to customer service.

8. Remove the flue gas analyser and close the test open-

ing at the flue gas analysis point.

9.13.5 Checking the gas flow rate

The gas flow rate has been set during production and does

not require adjustment. With the front casing fitted check the

gas flow rate of the boiler as follows:

▶ Check whether the front casing (vacuum chamber) has

been closed tightly.

▶ Start up the product with the check programme P.01.

▶ In addition, ensure that maximum heat can be dissipated

into the heating system by turning up the room thermo-

stat.

▶ Wait at least 5 minutes until the boiler has reached its

operating temperature.

▶ Ensure that all other gas appliances in the property are

turned off.

▶ Measure the gas flow rate at the gas meter.

▶ Compare the measured values with the corresponding

values in the table.

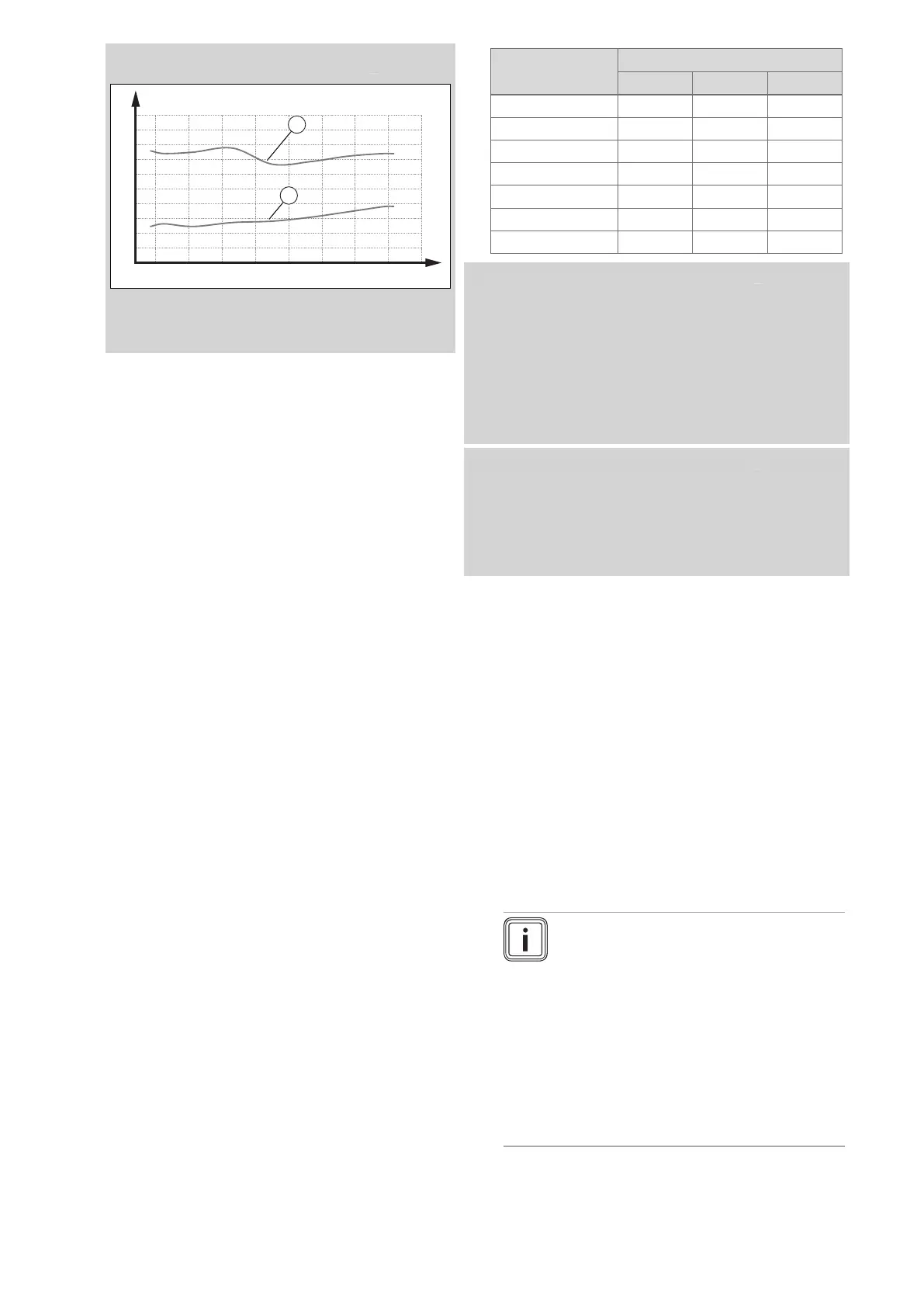

Qnw from the data

plate

H gas in m³/h

Nom. +5% −10%

15.3 1.62 1.70 1.46

18.4 1.95 2.05 1.76

24.7 2.61 2.74 2.35

25.7 2.72 2.86 2.45

28.6 3.03 3.18 2.73

30.6 3.24 3.40 2.92

35.7 3.78 3.97 3.40

Condition: Gas flow rate not in the permissible range

▶ Check the compliance with the local gas group.

(→ Section 9.13.1)

▶ Check the gas supply and monitor the flow pressure dur-

ing the test operation. (→ Section 9.13.3)

▶ Check all of the piping and ensure that the gas flow rates

are correct.

▶ Only put the product into operation once the gas flow

rates have been corrected.

Condition: Gas flow rate in the permissible range

▶ End the check programme P.01.

▶ Allow the boiler to cool down by allowing pump overrun to

operate for a minimum of 2 minutes.

▶ Record the boiler maximum gas flow rate onto the

Benchmark Checklist.

9.14 Thoroughly flushing the heating installation

("hot")

1. Operate the appliance until the boiler and the heating

system are up to temperature.

2. Check the heating system for leaks.

3. Connect a hose to the drain valve located at the lowest

position of the heating system.

4. Shut off the boiler, open the drain valve and all purge

valves on the radiators and allow the water to flow out

of the heating system and the boiler quickly and fully.

5. Close the drain valve.

6. Fill the heating system again with water as described

in Filling the heating installation (→ Section 9.9) and

Purging the heating installation (→ Section 9.10).

7. Re-fill the system until the system design pressure of

0,1 MPa (1,0 bar) is attained.

Note

The actual reading on the digital pressure

gauge should ideally be 0,05 MPa (0,5 bar)

plus an additional pressure corresponding

to the highest point of the system above

the base of the boiler – 10 m head equals

an additional 1 bar reading on the pressure

gauge. The minimum pressure should not

be less than 0,1 MPa (1 bar) in any install-

ation. If the system is to be treated with an

inhibitor it should be applied at this stage in

accordance with the manufacturer’s instruc-

tions.

Loading...

Loading...