0020308118_05 Installation and maintenance instructions 69

Appendix

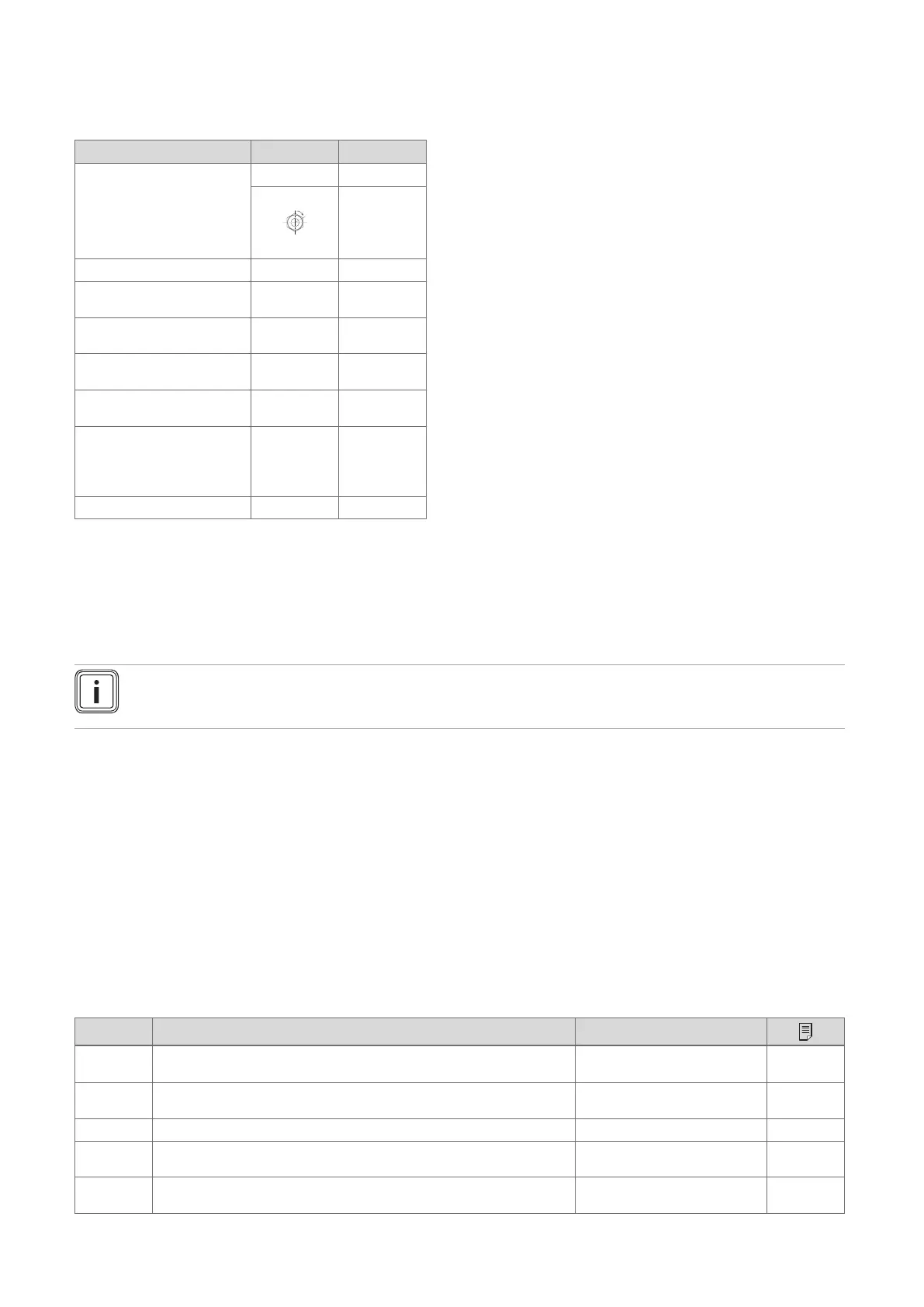

A Tightening torques

Manufacturer's recommendation for the tightening torques

Component Value Unit

Gas valve assembly, union

nut

40 Nm

15

60

Nm

+

Degrees

Burner, fixing screws 6 Nm

Fan flange, mixture pipe

screws

5.5 Nm

Fan, gas valve assembly

screws

5.5 Nm

Gas valve assembly, test

nipple screw plug

0.9 Nm

Gas isolation valve, test

nipple screw plug

1 Nm

Ignition electrode, fixing

screws

Control electrode, fixing

screws

3 Nm

Pump head, fixing screws 5 Nm

B Inspection and maintenance work

The table below lists the manufacturer requirements with respect to minimum inspection and maintenance intervals. If na-

tional regulations and directives require shorter inspection and maintenance intervals, you should observe these instead of

the intervals listed. Each time inspection and maintenance work is carried out, carry out the required preparatory and com-

pletion work.

Note

The country-specific specification for the maximum CO content has a higher value. With regard to the measured

CO content, first check the country-specific regulations before starting any measures.

As part of a combustion check that is carried out, (→ Section 9.13.4) a CO content of > 350 ppm undiluted is determined.

▶ Check the permissible total pipe length as well as the diameter of the air/flue system in accordance with the enclosed

valid set-up instructions for air/flue systems.

▶ Check whether the air/flue system has been installed correctly.

▶ Check whether the air/flue system is blocked and/or damaged.

The check was not completed with the result that the determined CO content is > 350 ppm.

▶ Replace the control electrode. (→ Section 13.7.14)

The control electrode has been replaced and the CO content is still > 350 ppm.

▶ Check the combustion chamber. (→ Section 12.8.2)

The combustion chamber has been inspected and the CO content is still > 350 ppm.

▶ Contact customer service.

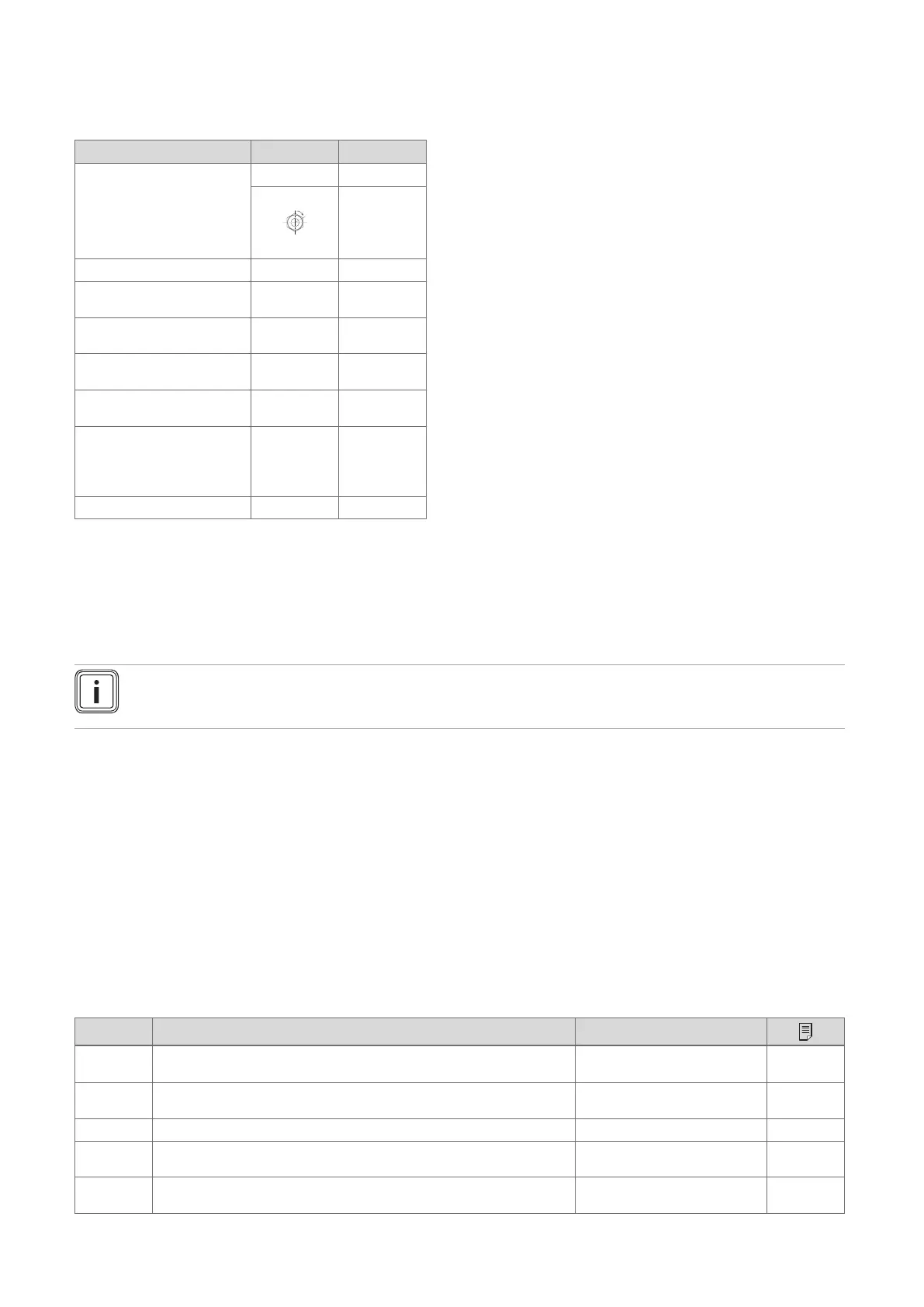

# Maintenance work Interval

1 Record all of the analysis results in the Benchmark Checklist in these

instructions

Annually

2 Ask the end user whether any significant problems occur when operating

the product

Annually

3 Use the diagnostics system to check the product's fault history Annually

4 Visually inspect whether the air/flue pipe and its opening have been in-

stalled correctly in accordance with the set-up instructions

Annually

5 Check that the unit has been installed correctly and the connections have

been secured

Annually

Loading...

Loading...