80 Installation and maintenance instructions 0020308118_05

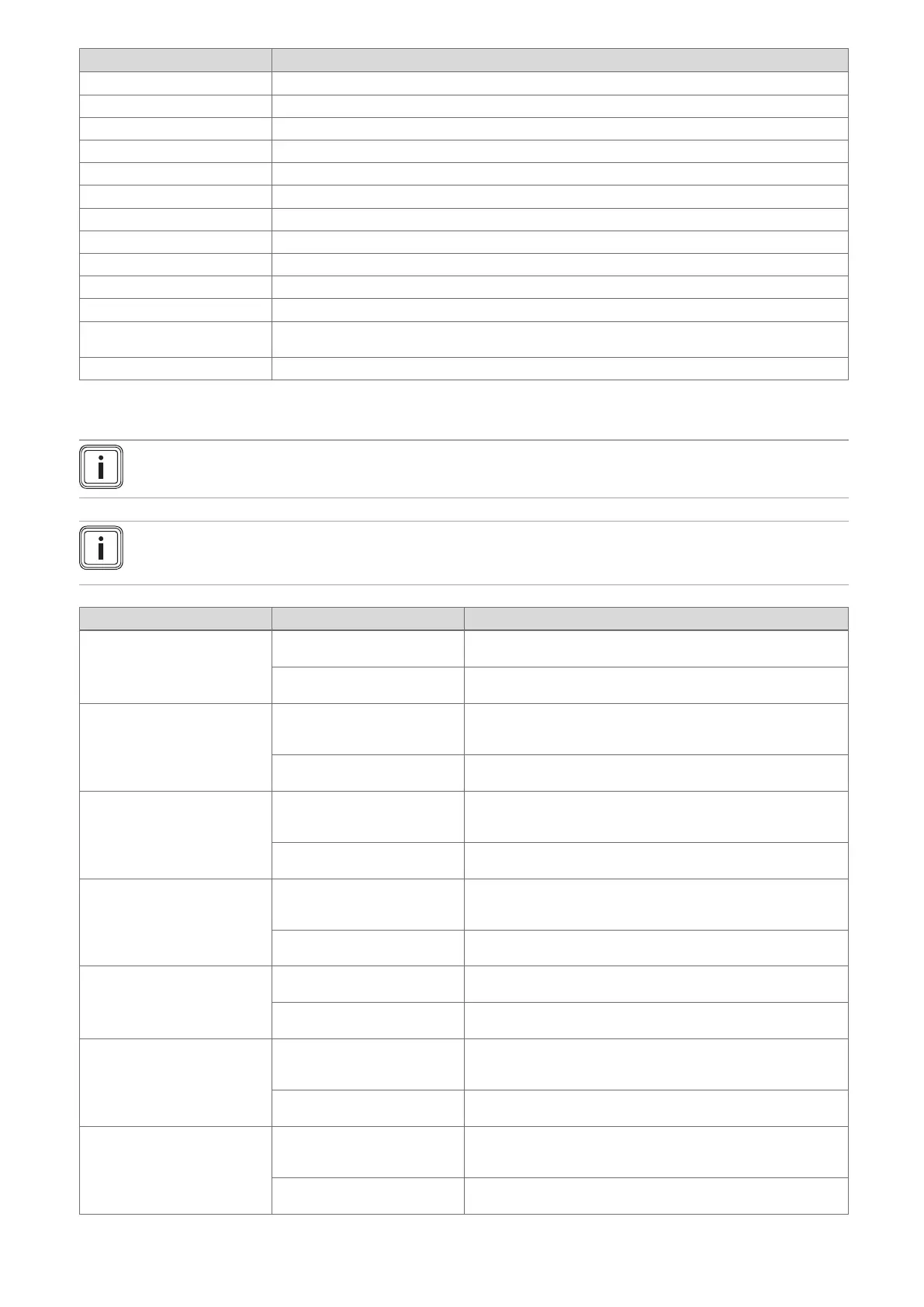

Code Meaning

S.092 The self-test for the circulation water volume is active.

S.093 A flue gas analysis is not currently possible.

S.096 The self-test for the return temperature sensor is active. The heat demands are blocked.

S.097 The self-test for the water pressure sensor is active. The heat demands are blocked.

S.098 The self-test for the flow and return temperature sensor is active. The heat demands are blocked.

S.109 The standby mode is active.

S.175 The installation assistant is in progress and all demands are blocked.

S.199 The unit is automatically filled with water.

S.326 The hydraulic sensor and actuator test is active.

S.328 The external pump runs continuously and is not connected to the unit.

S.335 Checking whether a flue gas blockage is present.

S.341 The unit temporarily decreases the load to the minimum modulation due to long, permanent burner

operation.

S.599 The unit has a fault.

F Fault codes

Note

Since the code table is used for various products, some codes may not be visible for the product in question.

Note

Due to a condensate blockage test after the last ignition attempt, fault messages F.028, F.029 and F.347 appear

after a delay. Wait for the fault displays.

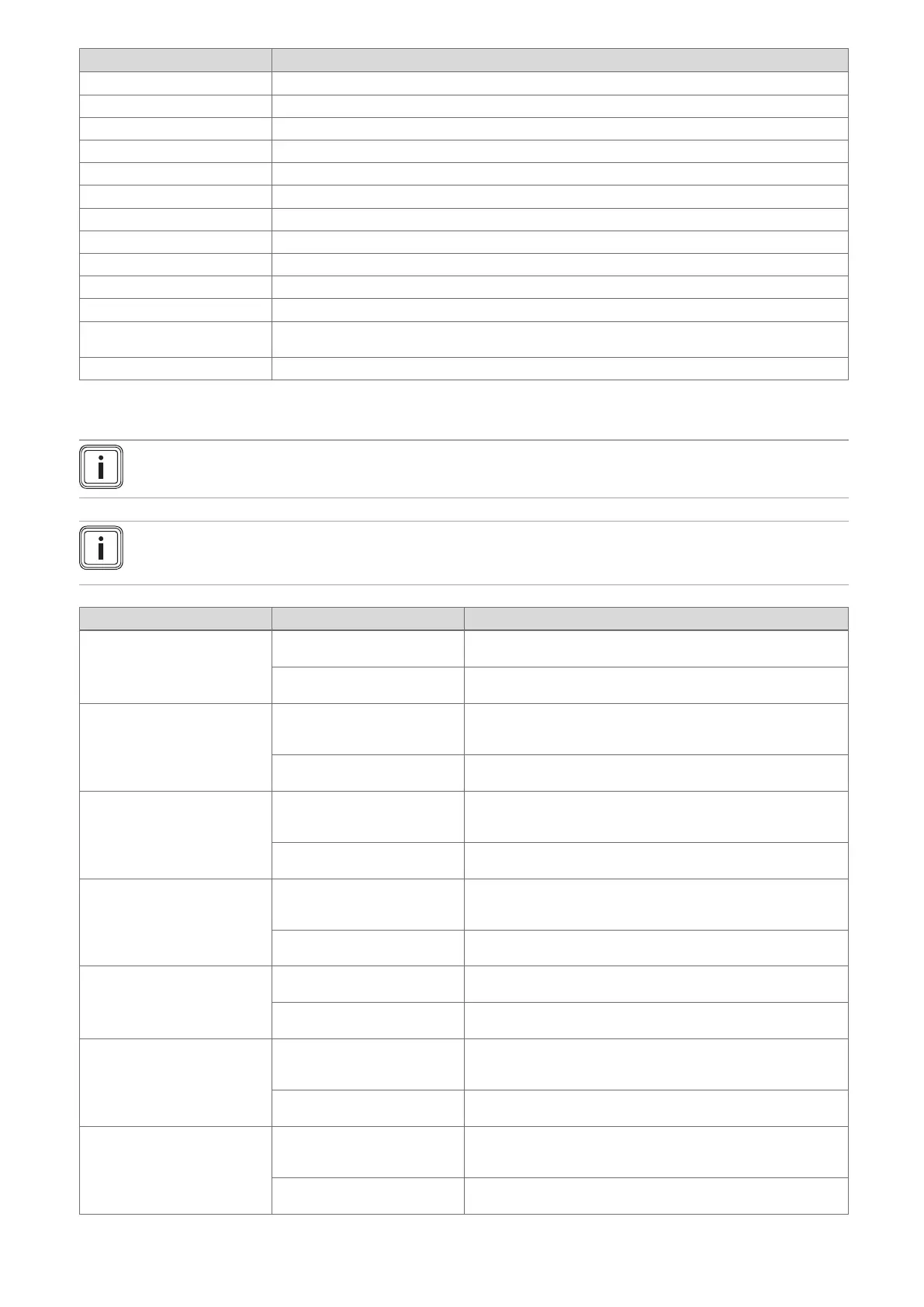

Code/meaning Possible cause Measure

F.000

The signal for the flow temper-

ature sensor has been interrup-

ted.

Fault in the electrical connection

for the flow temperature sensor

▶ Check and, if required, replace the wiring harness between the

PCB and sensor, including all plug connections.

Flow temperature sensor de-

fective

▶ Check and, if required, replace the flow temperature sensor.

F.001

The signal for the return tem-

perature sensor has been inter-

rupted.

Fault in the electrical connec-

tion for the return temperature

sensor

▶ Check and, if required, replace the wiring harness between the

PCB and sensor, including all plug connections.

Return temperature sensor de-

fective

▶ Check and, if required, replace the return temperature sensor.

F.002

The signal for the domestic hot

water connection temperature

sensor has been interrupted.

Fault in the electrical connection

for the domestic hot water tem-

perature sensor

▶ Check and, if required, replace the wiring harness between the

PCB and sensor, including all plug connections.

Domestic hot water temperature

sensor defective

▶ Check and, if required, replace the domestic hot water temper-

ature sensor.

F.003

The signal for the cylinder tem-

perature sensor has been inter-

rupted.

Fault in the electrical connection

for the cylinder temperature

sensor

▶ Check and, if required, replace the wiring harness between the

PCB and sensor, including all plug connections.

Cylinder temperature sensor

defective

▶ Check and, if required, replace the cylinder temperature

sensor.

F.010

The flow temperature sensor

has short-circuited.

Fault in the electrical connection

for the flow temperature sensor

▶ Check and, if required, replace the wiring harness between the

PCB and sensor, including all plug connections.

Flow temperature sensor de-

fective

▶ Check and, if required, replace the flow temperature sensor.

F.011

The return temperature sensor

has short-circuited.

Fault in the electrical connec-

tion for the return temperature

sensor

▶ Check and, if required, replace the wiring harness between the

PCB and sensor, including all plug connections.

Return temperature sensor de-

fective

▶ Check and, if required, replace the return temperature sensor.

F.012

The domestic hot water con-

nection temperature sensor has

short-circuited.

Fault in the electrical connection

for the domestic hot water tem-

perature sensor

▶ Check and, if required, replace the wiring harness between the

PCB and sensor, including all plug connections.

Domestic hot water temperature

sensor defective

▶ Check and, if required, replace the domestic hot water temper-

ature sensor.

Loading...

Loading...