66 Installation and maintenance instructions 0020308118_05

burner insulating mat on the rear of the combustion

chamber cover.

5. Remove the sealing residue from the burner flange.

Caution.

Risk of material damage caused by touch-

ing and cleaning.

The electrode may emit incorrect signals due

to changes in the surface.

▶ Only touch an electrode at the ceramic

section.

▶ Never clean an electrode.

6. Insert the new ignition electrode with a new seal (2).

7. Use two new screws to screw the ignition electrode in

tightly. Tightening torque, see appendix.

8. Reconnect the plug for the ignition electrode's ignition

line.

9. Reconnect the plug on the earth cable.

13.7.14 Replacing the control electrode

Danger!

Risk of death from hot flue gases!

Seals, screws and insulation on the control

electrode and combustion chamber must not

be damaged.

▶ Avoid damaging the burner insulating

mat on the back panel of the combustion

chamber cover.

▶ Replace the burner insulating mat as soon

as it shows signs of damage.

▶ Replace the seal and screws each time

you replace the control electrode.

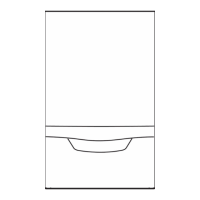

1. Remove the plug (1) for the control electrode's cable.

2. Unscrew both screws.

3. Thread the control electrode (4) carefully out of the

burner flange (3). Ensure that you do not damage the

burner insulating mat on the rear of the combustion

chamber cover.

4. Remove the sealing residue from the burner flange.

Caution.

Risk of material damage caused by touch-

ing and cleaning.

The electrode may emit incorrect signals due

to changes in the surface.

▶ Only touch an electrode at the ceramic

section.

▶ Never clean an electrode.

5. Insert the new control electrode with a new seal (2).

6. Use two new screws to screw the control electrode in

tightly. Tightening torque, see appendix.

7. Reconnect the plug for the control electrode's ignition

line.

8. Install the front casing. (→ Section 7.11)

9. Open the gas stopcock.

10. Connect the product to the power supply.

11. Activate diagnostics code D.147 via D.146.

(→ Section 8.3)

12. Set diagnostics code D.147 to New electrode

(→ Section 8.3).

13. Check the O₂ content. (→ Section 9.13.4)

13.7.15 Routing wiring harnesses

Note

High temperatures may damage wiring

harnesses.

Incorrect routing of the wiring harnesses may lead

to electromagnetic faults.

To prevent damage and faults, install the wiring

harnesses as shown in the figure.

Loading...

Loading...