XO 4 & XO FLEX TROUBLE SHOOTING GUIDE

Version 3.30 27

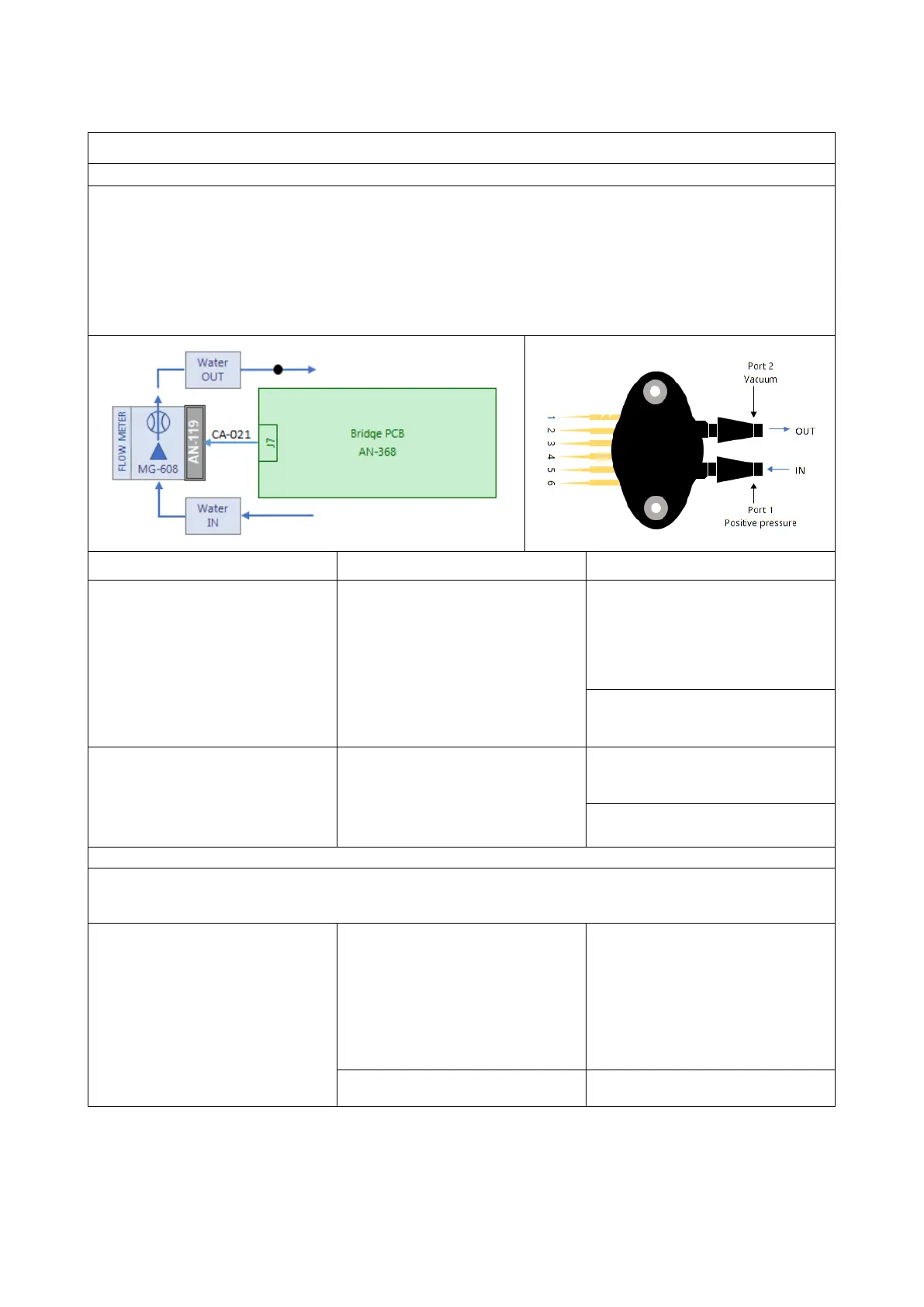

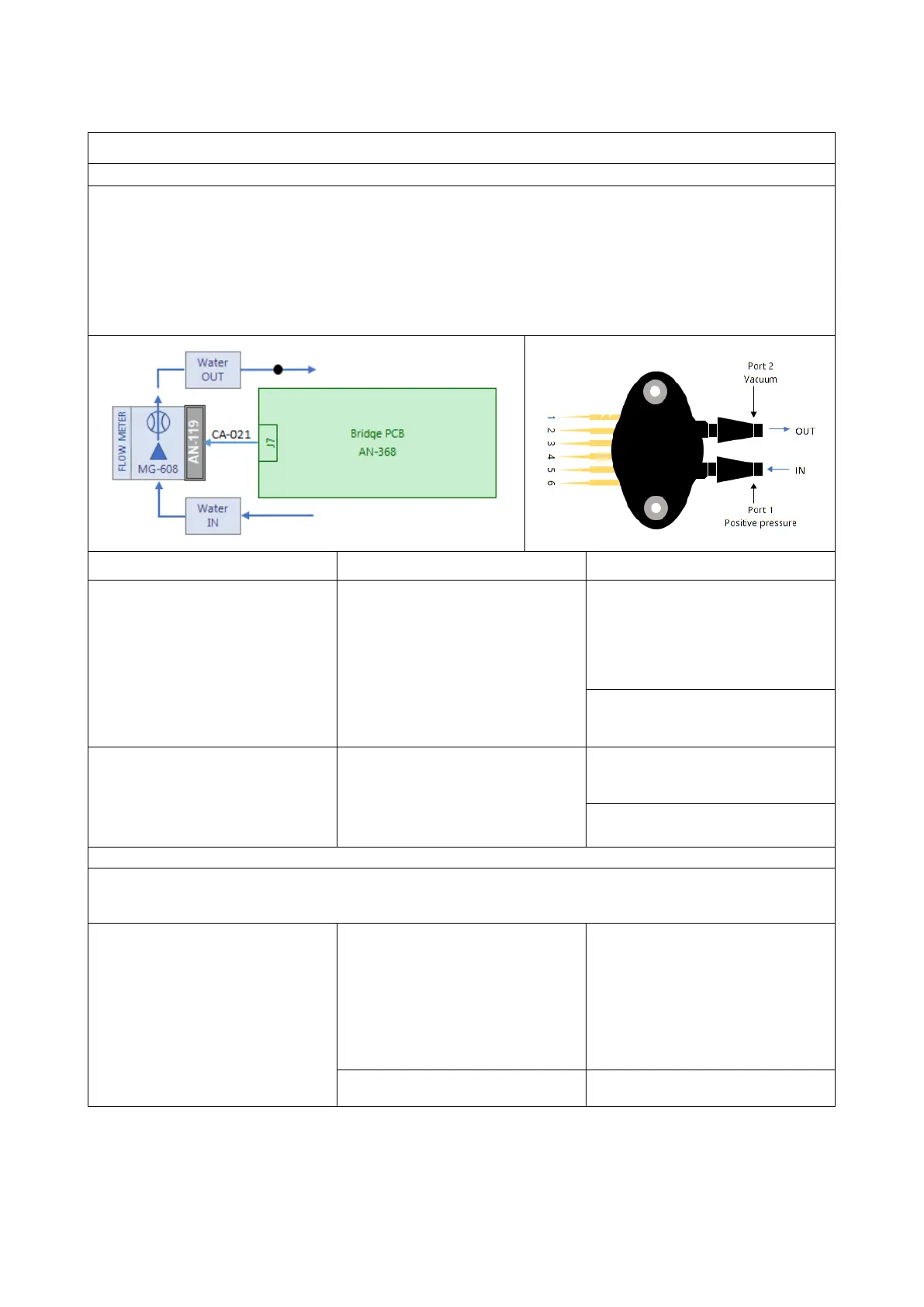

The flowmeter is equipped of a high viscosity monolithic silicon pressure sensor measuring the current

amount of water passing through the nozzle. The differential piezo-resistive transducer transmits the data

to the microprocessor on the “Bridge PCB AN-368”.

The proportional valve opens completely if the flow meter does not send signals to the microprocessor.

Max water quantity.

The flow meter is very sensitive to the reversal of the water passage which may damage it, the water

must flow in the direction indicated in the diagram below. A black dot for this purpose is located on the

green tube indicating the return of water.

Water arrives on the syringe

but not distributed on the

other instruments

The nozzle on the flow meter is

obstructed.

Remove and clean the nozzle on

the flow meter.

Follow the instructions in the

manual

“YB-910 Instruction cleaning

Check if the proportional valve

AN-903 is working properly (not

obstructed)

It is not possible to adjust

the flow rate on the

instruments.

The microprocessor does not

receive a signal from the flow

meter and the proportional valve

is open at maximum.

Check that the CA-021 cable is

correctly mounted. Change it if

defective.

Check that the flow meter is

working properly.

In case the water flow cannot be regulated (always 100%)

- Either the flow meter is defective

- Or the microprocessor doesn't convert the signals from the flowmeter

J7 Pin 4 (Analog Flow Output)

J7 Pin 5 (GND)

Stand-by = 321mV

When activating an instrument

J3 Pin 5 (Analog MUX Out)

J4 Pin 3 (GND)

Stand-by = 297mV

When activating an instrument

50 ml = 1,20 V

50 ml = 0,90 V

If no variation, change the

“Flowmeter AP-921”

If no variation, change the

“Bridge PCB AN-368”.

Loading...

Loading...