XO 4 & XO FLEX TROUBLE SHOOTING GUIDE

Version 3.30 59

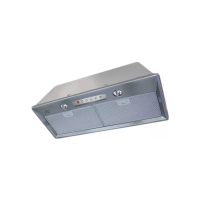

The liquid detection sensor

pins do not work properly.

It is important that the 3 sensor pins

have no contact with the inner

surface of the mixing cup or partition

wall.

Correct the sensor probes to ensure

that they do not touch the inner

surface of the mixing cup.

Check that the partition wall is

inserted into the grooves of the cup

Lower LED off (Mixing cup

filled)

Sensor PCB is defective or defective

cable.

if the LED flashes it might indicate

that the cable is defective, or has a

short circuit change the cable.

Check the connections of the "Water

clean" cable CA-033 or “Suction

Clean” cable CA-008.

If it continues to flash change AP-

869 PCB.

when water reaches the

short liquid detector sensor

probes.

Ether the sensor pins on PCB or the

cable are defective.

if the LED flashes it might indicate

that the cable is defective, or has a

short circuit change the cable,

Check the connections “Water

clean” cable CA-007 or CA-008 for

“Suction Clean” cable.

If it continues to flash change AP-

869 PCB.

NOTE: It is important that the PCB is dry and clean.

Do not touch the PCB if you have grease, suction system disinfection liquid on your fingers. The

electronics of the AP-869 (AD-620) PCB is very sensitive.

The sensors control the levels in the mixing cup. The filling of the liquid stops when the upper level is

reached (short spindle).

Filling starts again when the lower level is reached (no liquid between the two long spindles).

The sensors are very sensitive and can be tested with a wet finger.

Loading...

Loading...