XO 4 & XO FLEX TROUBLE SHOOTING GUIDE

Version 3.30 61

Control the condition of the cable

CA-033 and replace it if damaged

dispenser detected as "low"

when full (white bottle).

The liquid sensor S14 measuring the

water treatment fluid in the reservoir

is not properly aligned, obturated or

is defective

Measures the content of the suction

clean dispenser located in the

Check that there is no gap between

the sensor and the dispenser.

If necessary, adjust the liquid sensor

and secure that the dispenser is

Verify that the rubber support is

good condition and does not

obturate the 2 photos electric

sensors. Replace the rubber support

Replace The liquid sensor PCB AN-

374.

The liquid in the bottle does

not circulate

The pump does not work properly.

Check if the pump is working

properly, the session takes 2

seconds.

Check that the liquid is flowing

through the unit from the “Water

Clean” bottle to the mixing cup.

Measure the voltage at the pump

V31 connections

(+24 VDC)

Measure the pumps coil resistance.

Disassemble and clean the valve at

the piston.

Change the seat gasket

The peroxide tends to create crystals in the pump if the unit has not been in use for a certain period.

Procedure : How to activate the pump

Units produced before September 2018:

Disconnect the neutral and connect it to the ground on the chassis, the V31 pump will prime.

Units produced after September 2018: date of separation of earth and logic 0V

The procedure to prime the pump can be done with a cable CA-049 connected to the 24VDC Jumper

J26 or J36 which is on the Backplane. For more information: see page 19 “Backplane AN-369”

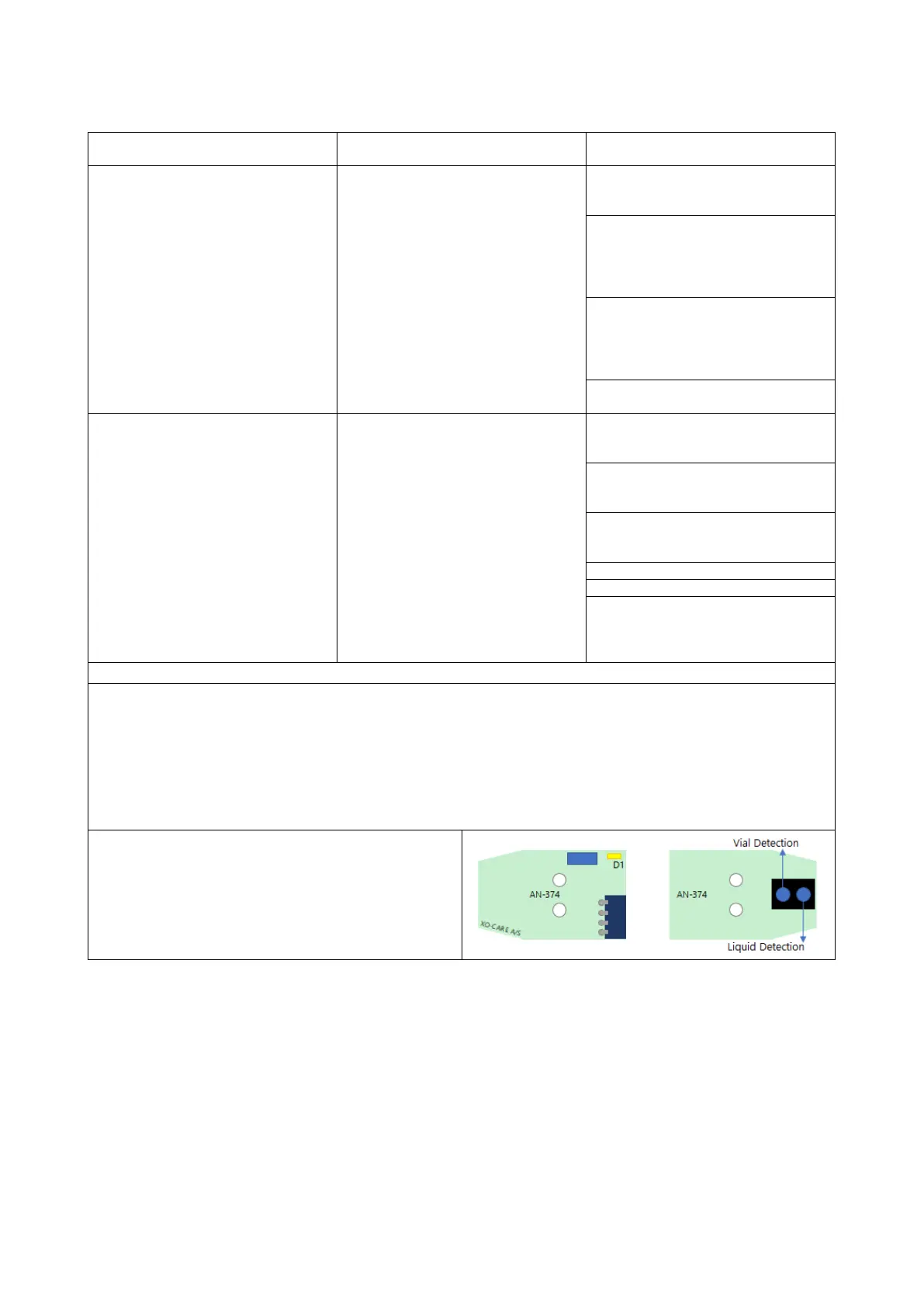

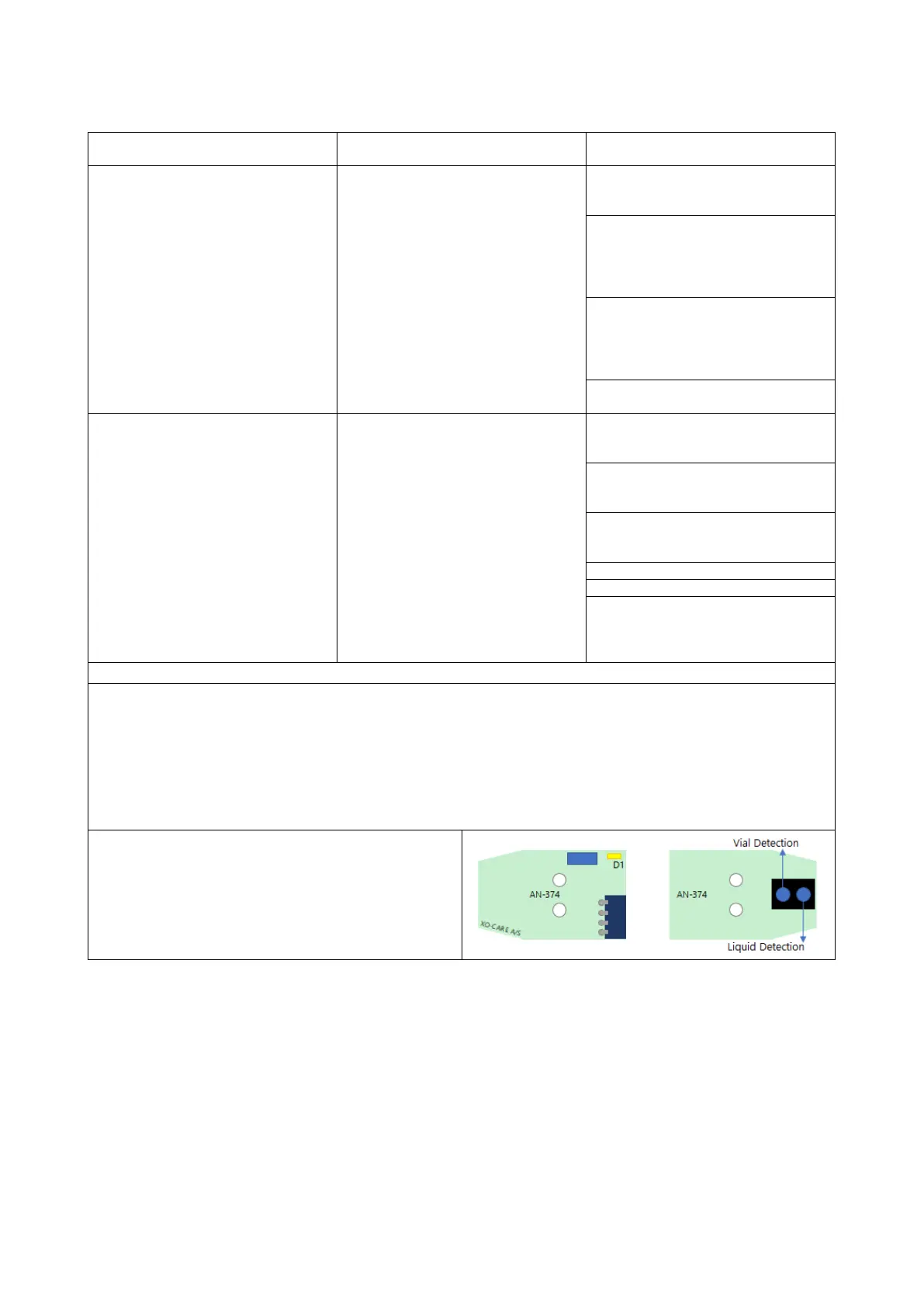

AN-374 Level Sensor PCB

Loading...

Loading...