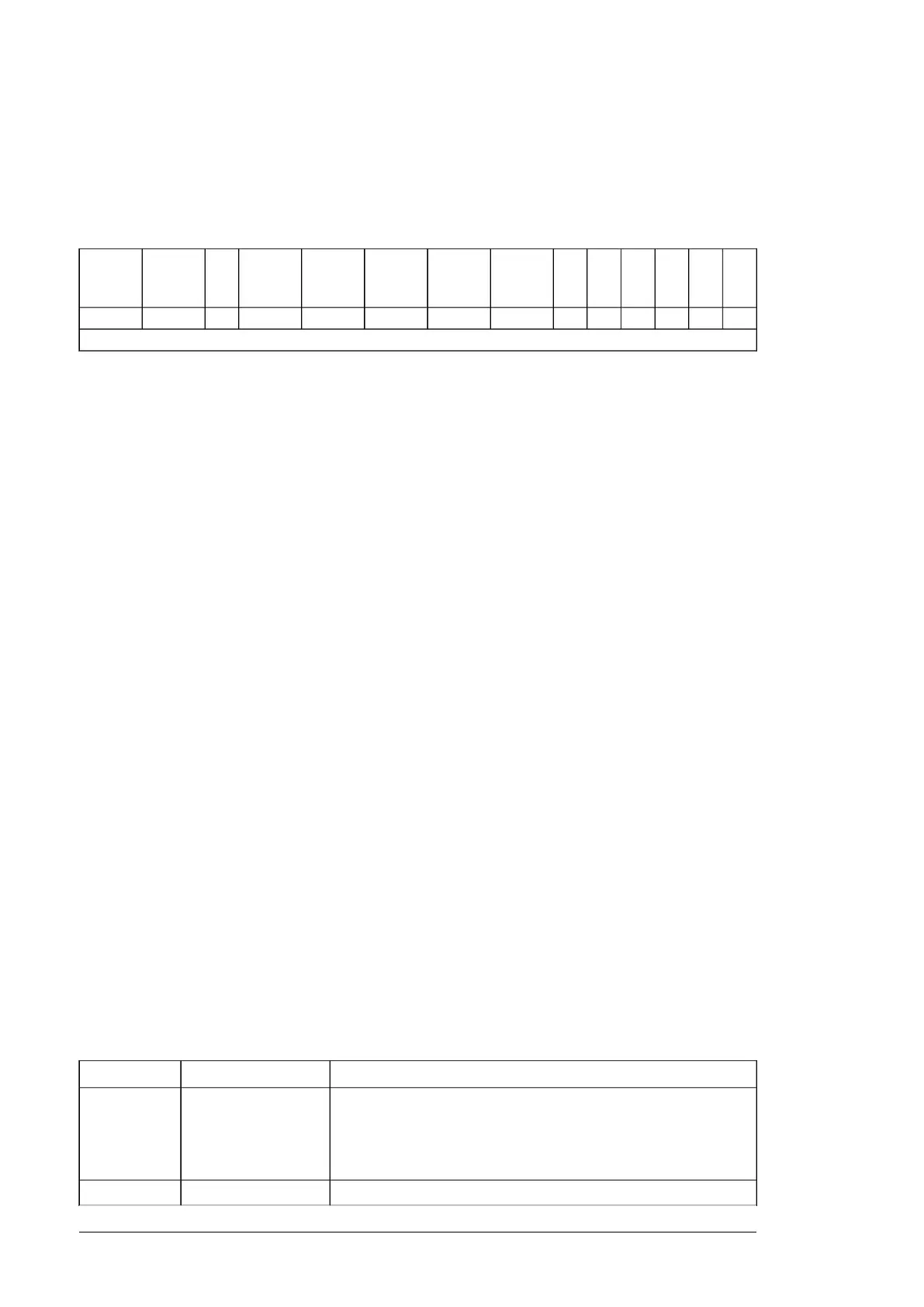

Safety data

The safety data for the Safe torque off function is given below.

Note: The safety data is calculated for redundant use, and does not apply if both STO

channels are not used.

T

M

(a)

CCFHFTSCCat.

DC

(%)

MTTF

D

(a)

PFD

avg

(T

1

= 5 a)

PFD

avg

(T

1

= 2 a)

PFH

(T

1

= 20 a)

(1/h)

SFF

(%)

PL

SIL/

SILCL

Frame size

2080133≥90163989.08E-053.63E-054.14E-0999.61e3R11

3AXD10000410558 F

• The following temperature profile is used in safety value calculations:

•

670 on/off cycles per year with ΔT = 71.66 °C

•

1340 on/off cycles per year with ΔT = 61.66 °C

•

30 on/off cycles per year with ΔT = 10.0 °C

• 32 °C board temperature at 2.0% of time

• 60 °C board temperature at 1.5% of time

• 85 °C board temperature at 2.3% of time.

• The STO is a type A safety component as defined in IEC 61508-2.

• Relevant failure modes:

• The STO trips spuriously (safe failure)

• The STO does not activate when requested

• A fault exclusion on the failure mode “short circuit on printed circuit board” has been

made (EN 13849-2, table D.5). The analysis is based on an assumption that one

failure occurs at one time. No accumulated failures have been analyzed.

• STO response times:

• STO reaction time (shortest detectable break): 1 ms

• STO response time: 2 ms (typical), 30 ms (maximum)

• Fault detection time: Channels in different states for longer than 200 ms

• Fault reaction time: Fault detection time + 10 ms

• Indication delays:

•

STO fault indication (parameter 31.22) delay: < 500 ms

•

STO warning indication (parameter 31.22) delay: < 1000 ms

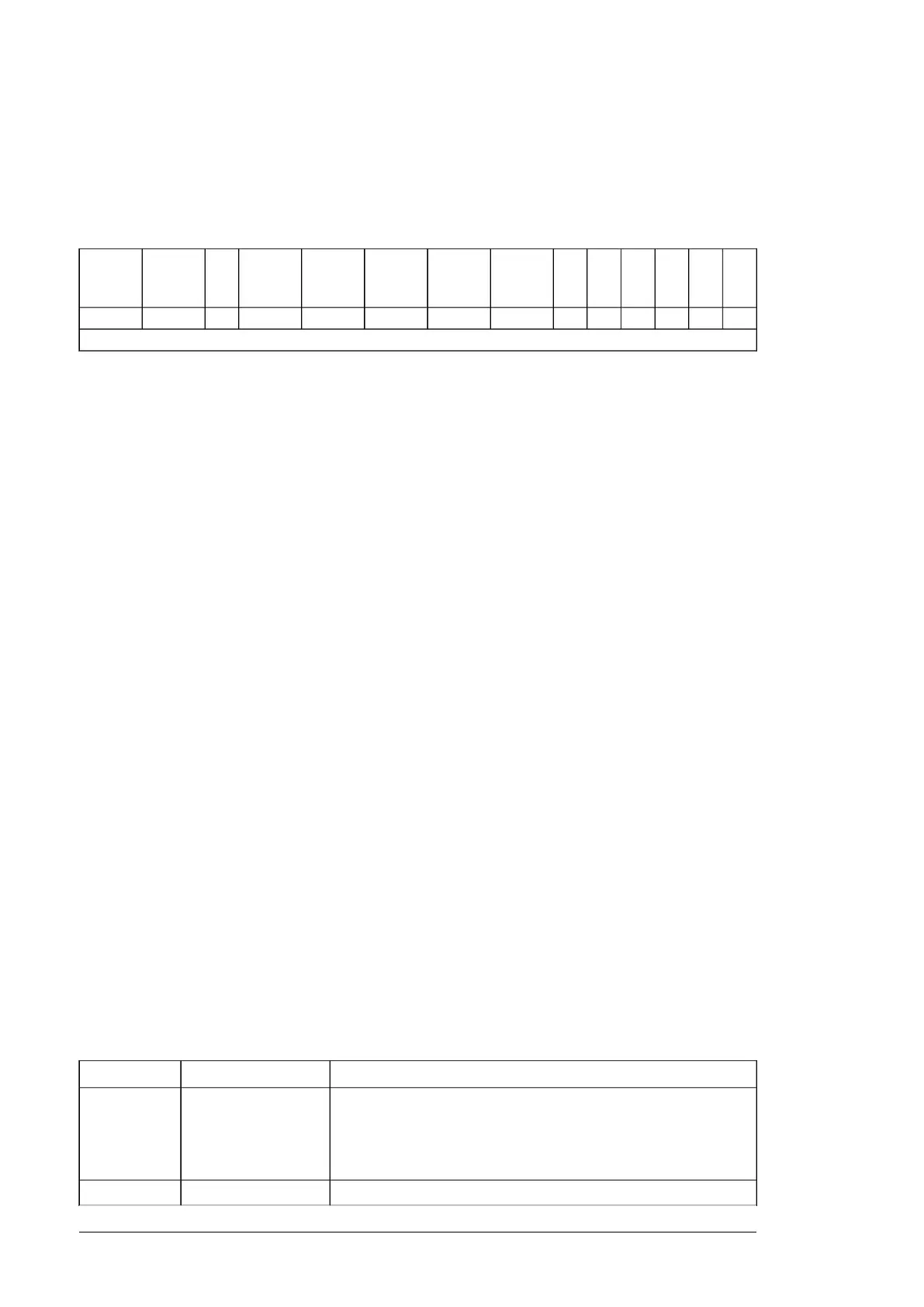

■ Abbreviations

DescriptionReferenceAbbr.

Classification of the safety-related parts of a control system in respect

of their resistance to faults and their subsequent behavior in the fault

condition, and which is achieved by the structural arrangement of the

parts, fault detection and/or by their reliability. The categories are: B,

1, 2, 3 and 4.

EN ISO 13849-1Cat.

Common cause failure (%)EN ISO 13849-1CCF

206 The Safe torque off function

Loading...

Loading...