Program features 75

Example 2: If the reference switching frequency is set to 12 kHz and the minimum

switching frequency is set to 1.5 kHz (or 1 kHz), the drive maintains the highest

possible switching frequency to reduce motor noise and only when the drive heats it

will decrease the switching frequency. This is useful, for example, in applications

where low noise is necessary but higher noise can be tolerated when the full output

current is needed.

Parameters

Parameter: 97.01 Switching frequency reference and 97.02 Minimum switching

frequency.

Speed compensated stop

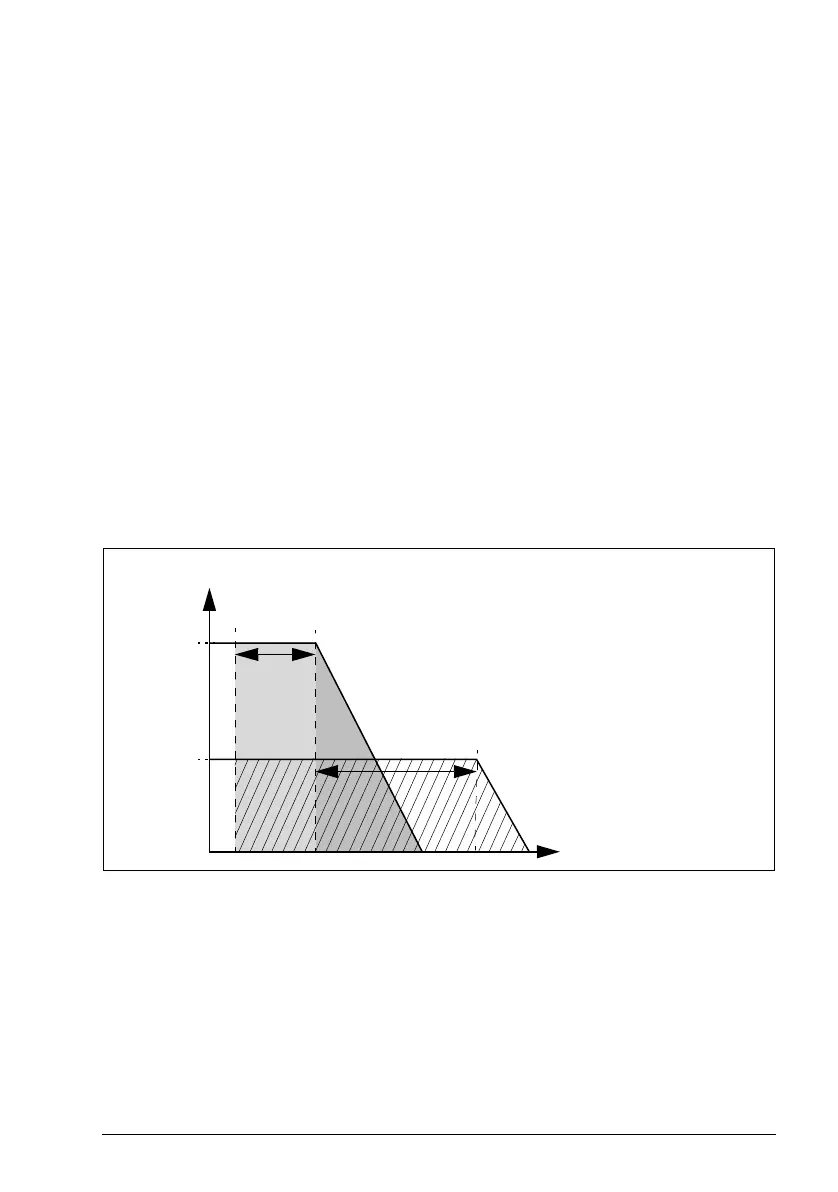

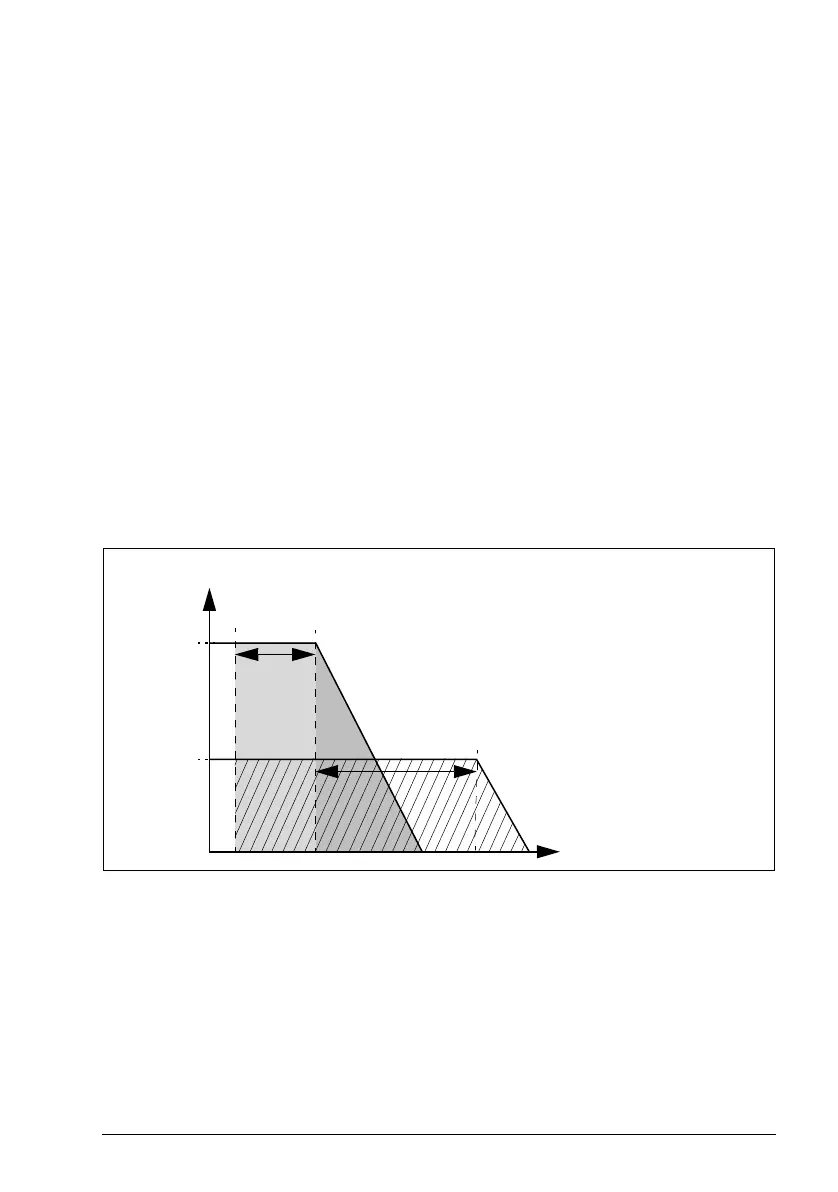

Speed compensation stop is available for example for applications where a conveyer

needs to travel a certain distance after receiving the stop command. At maximum

speed, the motor is stopped normally along the defined deceleration ramp, after the

application of a user defined delay to adjust the distance traveled. Below maximum

speed, stop is delayed still more by running the drive at current speed before the

motor is ramped to a stop. As shown in the figure, the distance traveled after the stop

command is the same in both cases, that is, area A + area B equals area C.

Speed compensation does not take into account shape times (parameters 23.32

Shape time 1 and 23.33 Shape time 2). Positive shape times lengthen the distance

traveled.

Speed compensation can be restricted to forward or reverse rotating direction.

Speed compensation is supported in both vector and scalar motor control.

Parameters

Parameters: 21.30 Speed compensated stop mode, 21.31 Speed compensated stop

delay and 21.32 Speed comp stop threshold.

Used

speed

A

Motor speed

Max.

speed

B

C

t (s)

Area A + Area B = Area C

Stop

command

D1

D1 = Delay defined by parameter

21.31

D2 = Additional delay calculated by

speed compensated stop

D2

Loading...

Loading...