Flange seals and static seals

The following procedure describes how to fit flange seals and static seals.

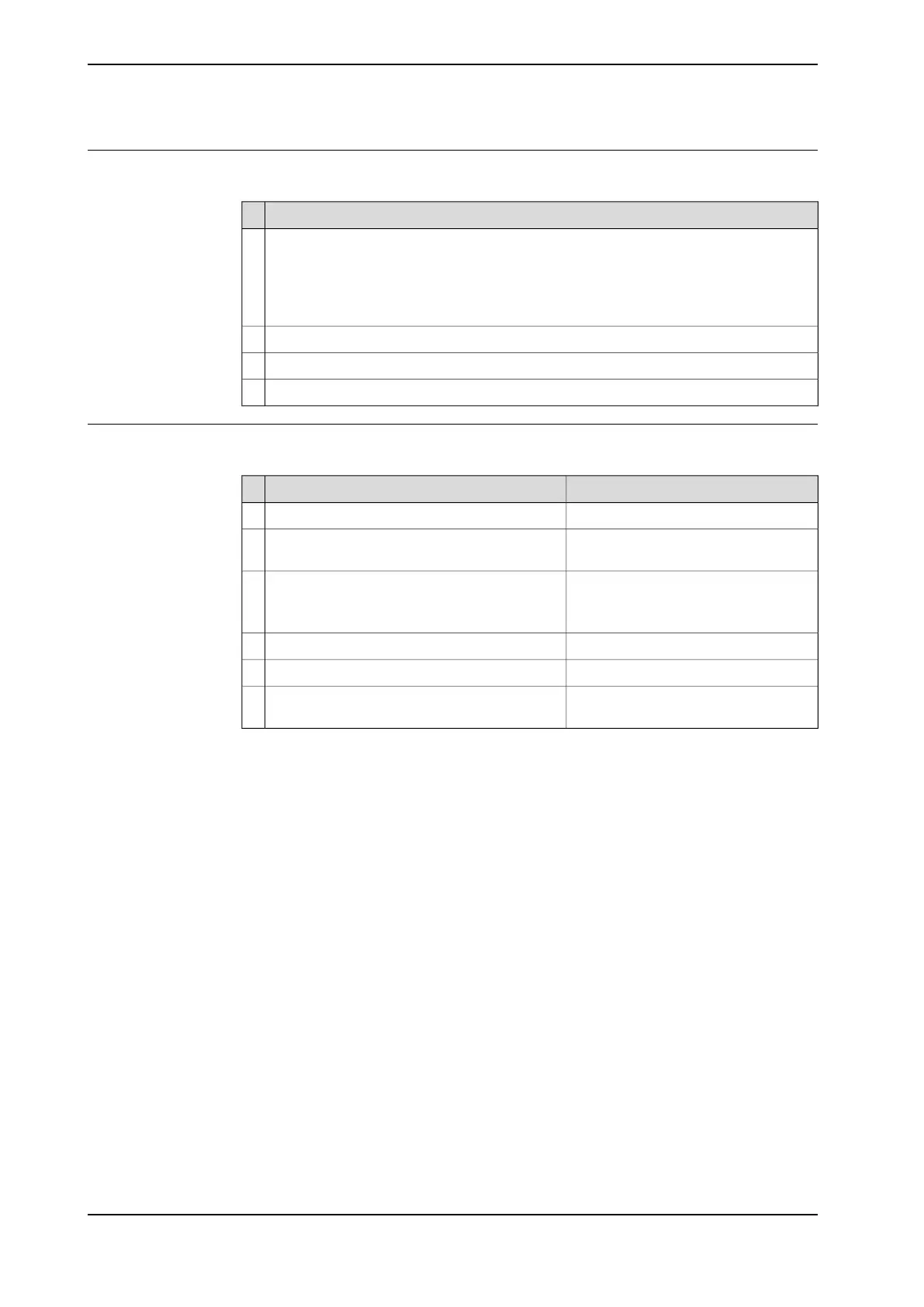

Action

Check the flange surfaces. They must be even and free from pores.1

It is easy to check flatness using a gauge on the fastened joint (without sealing com-

pound).

If the flange surfaces are defective, the parts may not be used because leakage could

occur.

Clean the surfaces properly in accordance with the recommendations of ABB.2

Distribute the sealing compound evenly over the surface, preferably with a brush.3

Tighten the screws evenly when fastening the flange joint.4

O-rings

The following procedure describes how to fit o-rings.

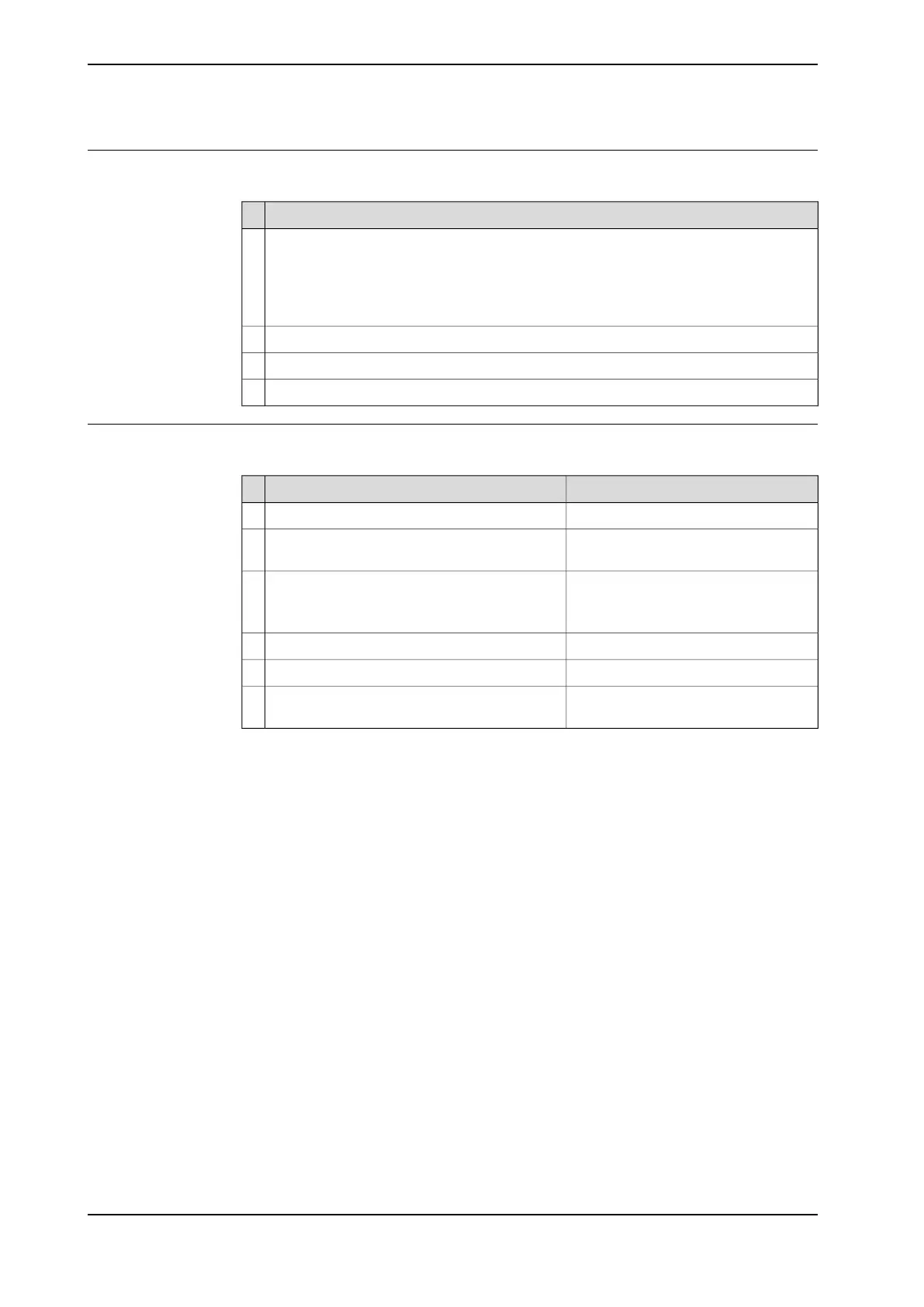

NoteAction

Ensure that the correct o-ring size is used.1

Defective o-rings, including damaged

or deformed o-rings, may not be used.

Check the o-ring for surface defects, burrs,

shape accuracy, or deformation.

2

Defective o-rings may not be used.Check the o-ring grooves.3

The grooves must be geometrically correct and

should be free of pores and contamination.

Lubricate the o-ring with grease.4

Tighten the screws evenly while assembling.5

Make sure that no grease is left on the robot

surface.

192 Product manual - IRB 2600

3HAC035504-001 Revision: Q

© Copyright 2009-2018 ABB. All rights reserved.

4 Repair

4.2.3 Mounting instructions for seals

Continued

Loading...

Loading...