- 59 - UMC100-FBP

Universal Motor Controller

UMC100-FBP

Technical Description

FieldBusPlug / Issue: 03.2012

5 Configuring the Motor Management Functions

In this section you find the following information:

•Introduction into the supported control stations and operation modes

•How to start and stop the motor from the different control stations

•Available control functions

•Functions related to motor control such as emergency start, checkback monitoring etc.

Starting and Stopping the Motor

Control Stations

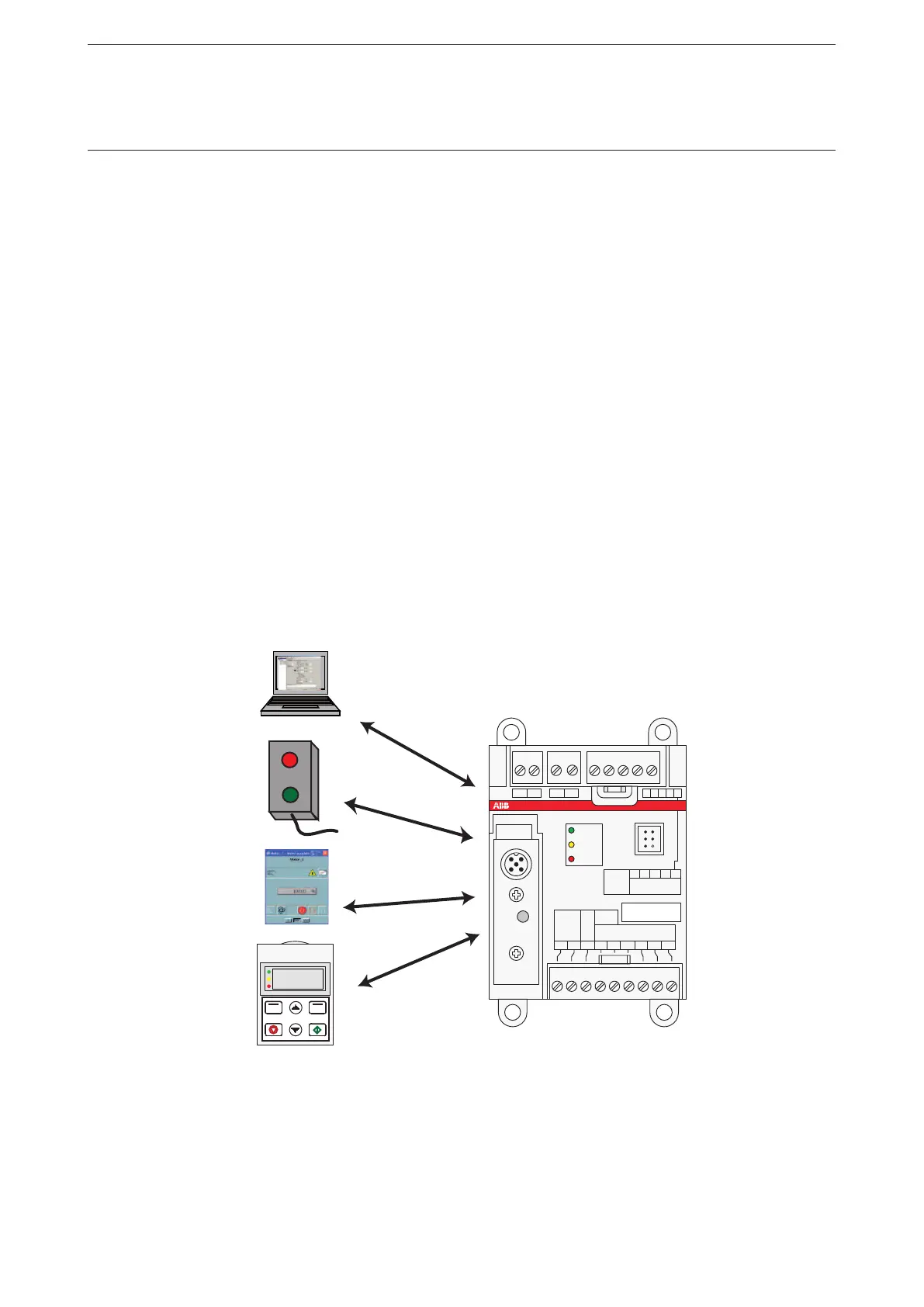

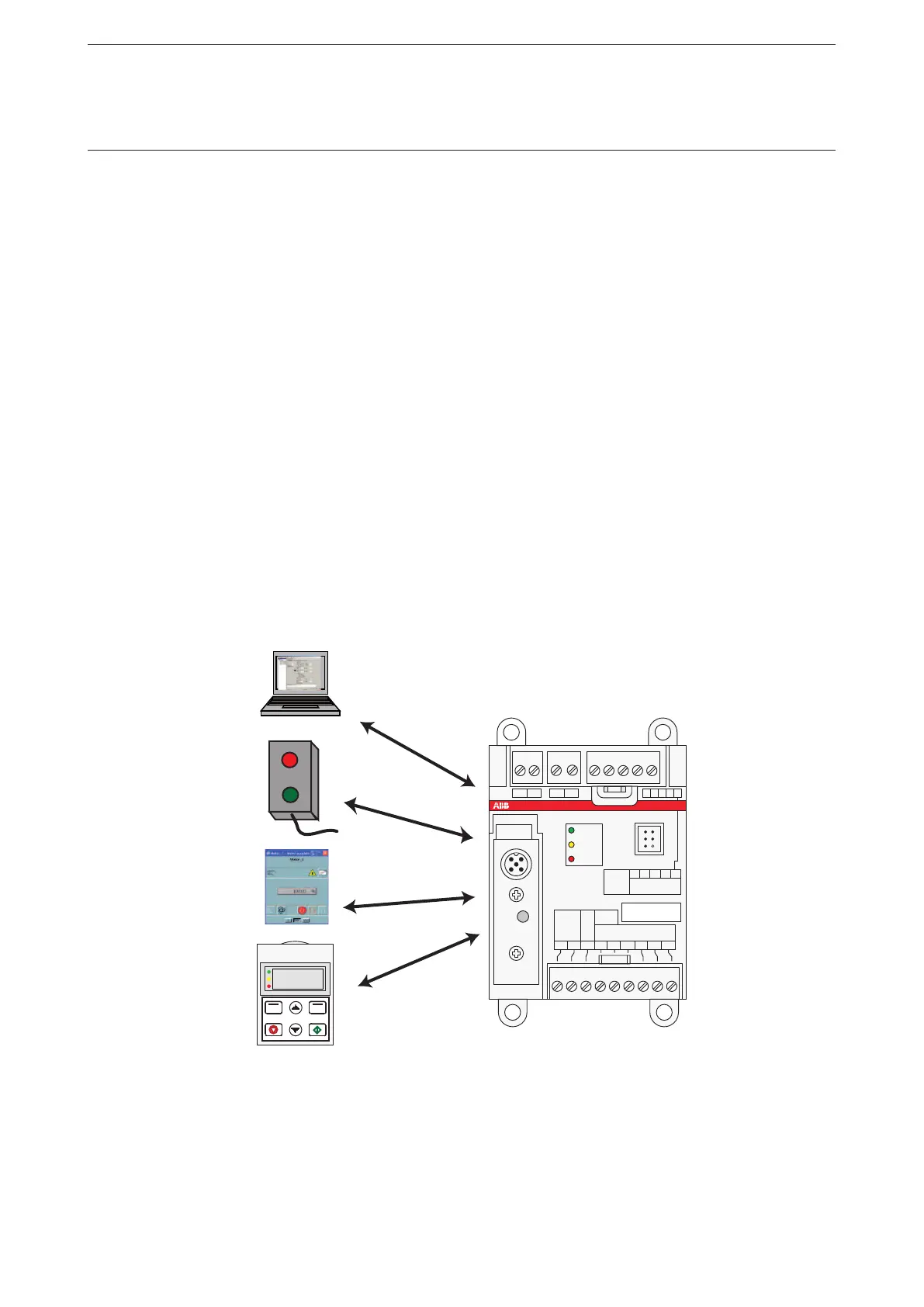

From control stations (i.e. source of commands) start/stop commands can be sent to the UMC. Four

control stations are supported:

•Digital Inputs: Allow the motor to be controlled from a control panel with push buttons e.g. mounted lo-

cally to the motor.

•DCS/PLC: Commands are transferred via cyclic communication telegrams from the process control-

ler via fieldbus to the UMC. The UMC uses the PNO motor starter profile which defines the meaning of

each bit in the cyclic telegrams. See section XXX for further details.

•LCD-Panel: Allows control via the buttons of the UMC-PAN usually mounted in the switchgear cabinet

door

•Service Tool: Allows control commands to be issued via acyclic communication services of the used

fieldbus. The UMC DTM uses this communication channel for example.

For each control station you can configure if a start and/or a stop command is accepted by the UMC.

o

I

181716151413121110

DIDIDIDIDIDI

24V

240

543210OutVV

Powe r

T1

8

DO

1

7

DO

0

6

DO

C

5

DO

C

9

DO

2

8765 9T2 Ca Cb

UMC100

READY

MOT.O N

FAUL T

Rela y

230V AC

1A

Inputs

24VDC

DC

Modes

In practise it is often required to release or block start/stop commands from a control station depending

on various reasons e.g.

•If the communication to the bus master is interrupted you want to automatically enable control via digital

inputs which would not be possible if the communication is ok

•For service purposes all commands from the bus should be ignored

•...

Loading...

Loading...