Behavior models used in CIP Motion

Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018 29

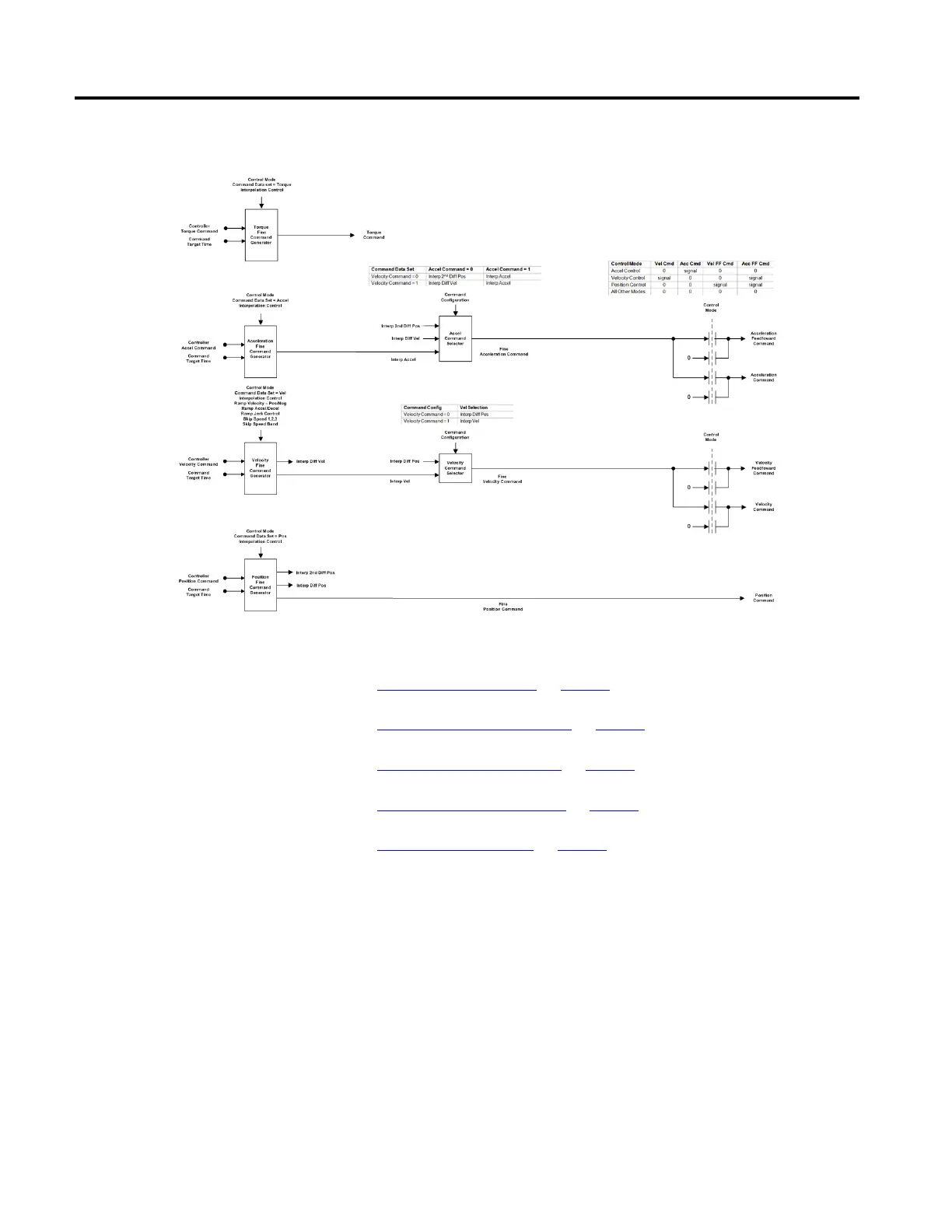

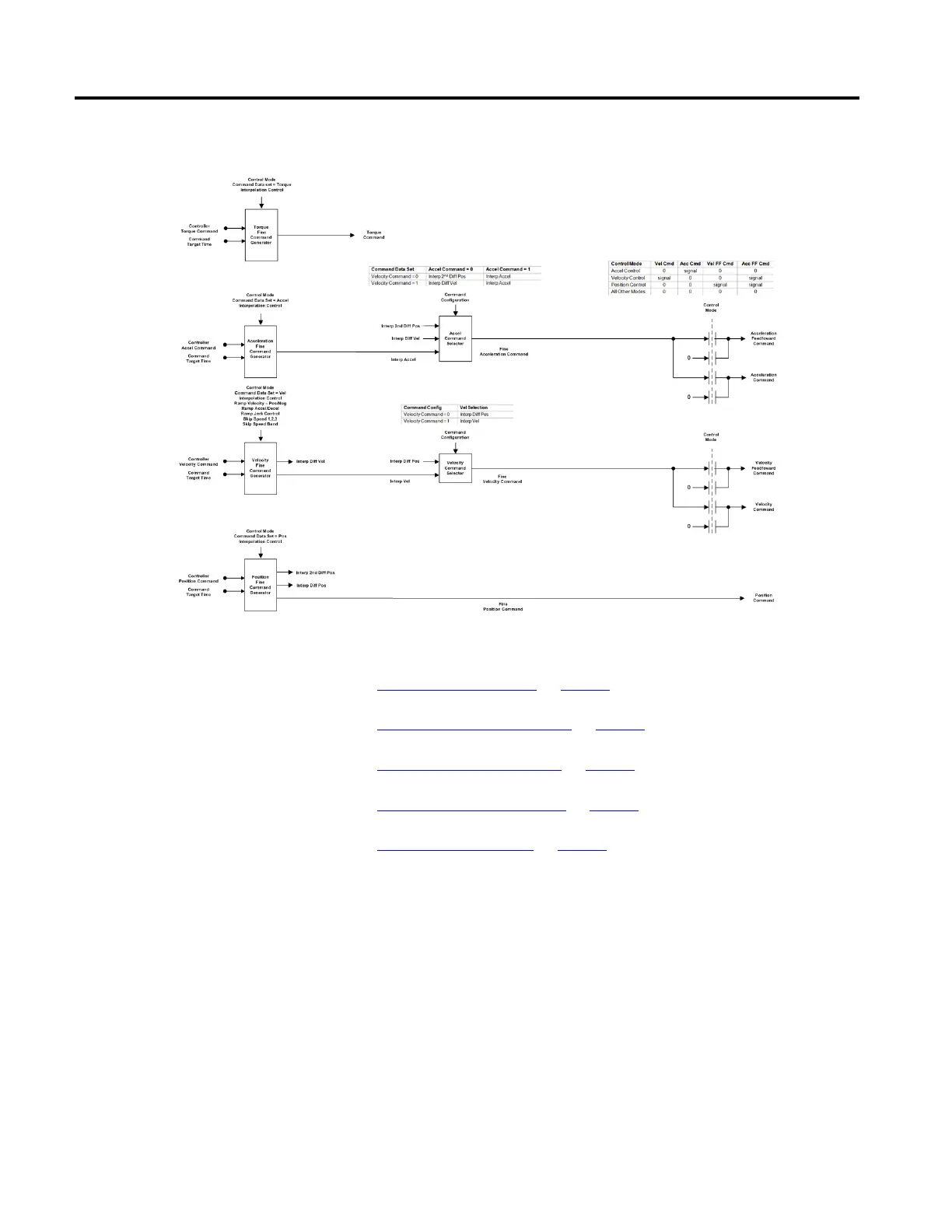

The following diagram illustrates the interaction command generation behavior:

See also

Command Data Sources on page 29

Command Fine Interpolation on page 30

Command Ramp Generator on page 33

Feedforward Signal Selection on page 34

Command Notch Filter on page 35

Command data that impacts axis motion can come from a variety of sources. The

most common command data source is from a controller-based Motion Planner

using the CIP Motion C-to-D Connection. In this context, command data can

take the form of Controller Position, Velocity, Acceleration, and Torque

Commands generated by the Motion Planner. The command data elements

provided are specified by the Command Data Set attribute, which is based on the

selected Control Mode. The primary command data element can be augmented by

higher order command elements for the purposes of generating high quality

feedforward signals. Alternatively, these higher order command elements can be

derived by the device from the primary command data. In either case, a Fine

Command Interpolator is generally applied to the Command Data to generate

Loading...

Loading...