Publication 1763-RM001C-EN-P - October 2009

298 Process Control Instruction

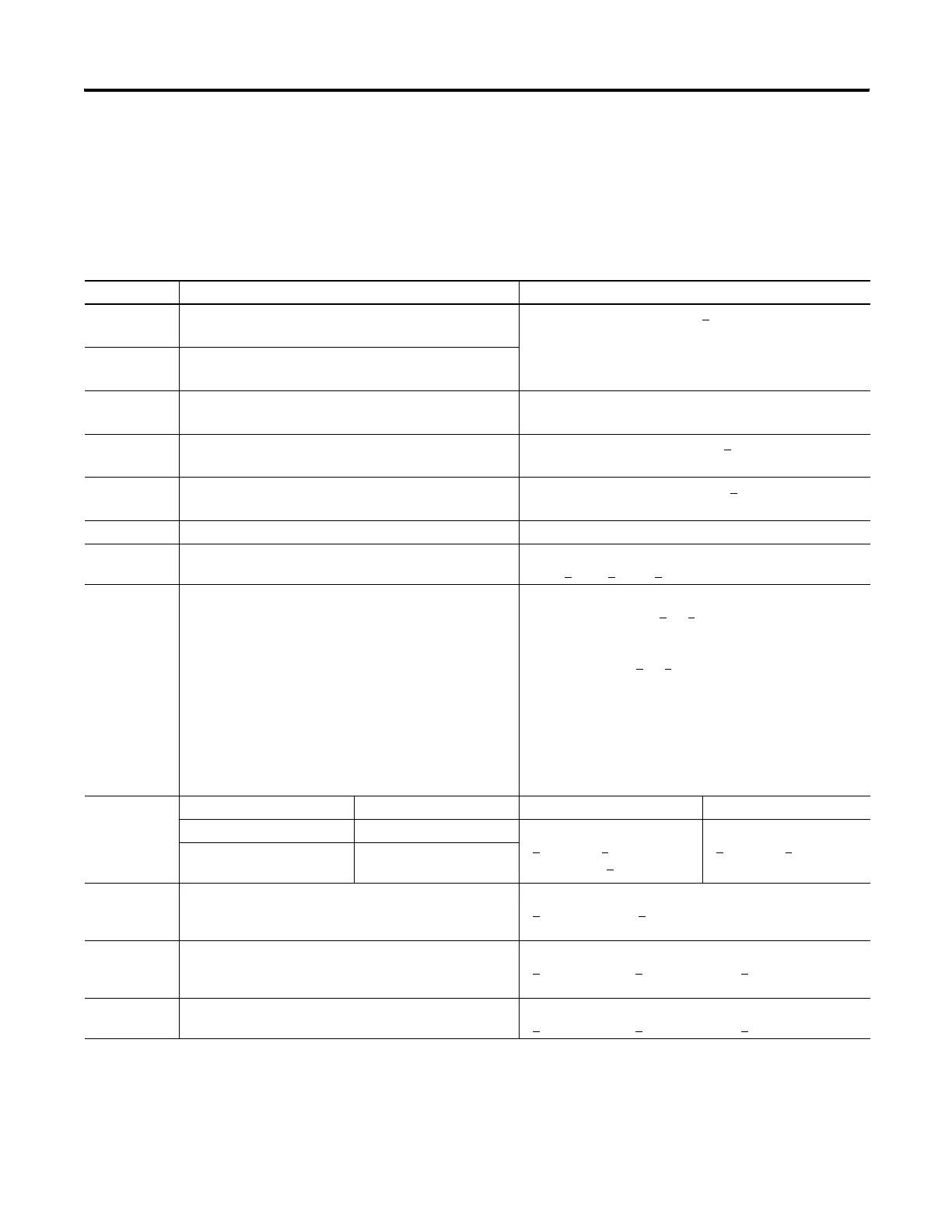

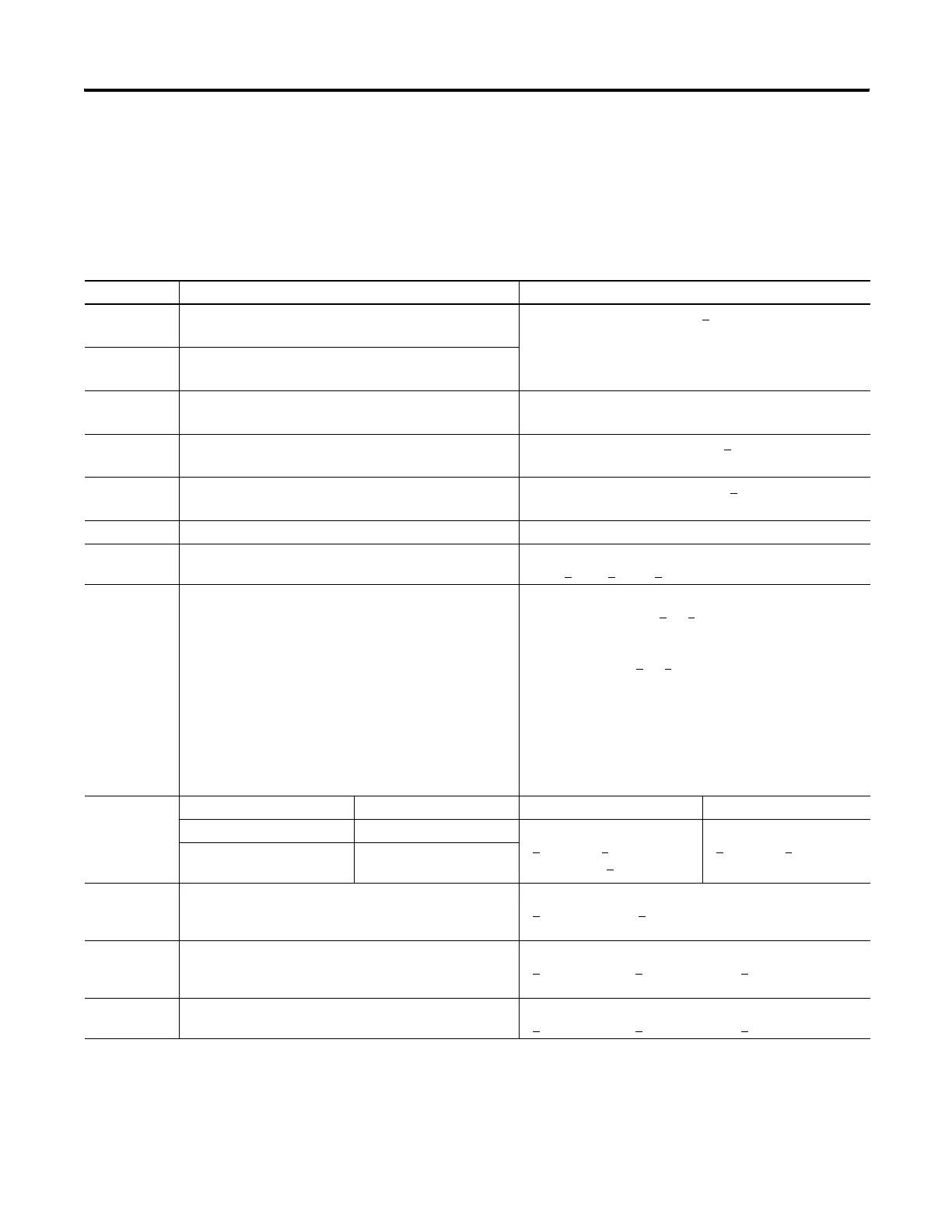

Runtime Errors

Error code 0036 appears in the status file when a PID instruction runtime

error occurs. Code 0036 covers the following PID error conditions, each

of which has been assigned a unique single byte code value that appears

in the MSB of the second word of the control block. The error code is also

displayed on the PID Setup Screen in RSLogix 500.

Error Code Description of Error Condition or Conditions Corrective Action

11H 1. Loop update time

D

t

> 1024

Change loop update time 0 < D

t

< 1024

2. Loop update time

D

t

= 0

12H Proportional gain

K

c

< 0

Change proportional gain K

c

to 0 < K

c

13H Integral gain (reset)

T

i

< 0

Change integral gain (reset) T

i

to 0 < T

i

14H Derivative gain (rate)

T

d

< 0

Change derivative gain (rate) T

d

to 0 < T

d

15H Feed Forward Bias (FF) is out-of-range. Change FF so it is within the range -16383 to +16383.

23H Scaled setpoint min

MinS > Scaled setpoint max MaxS

Change scaled setpoint min MinS to

-32768 <

MinS < MaxS < +32767

31H If you are using setpoint scaling and

MinS > setpoint SP > MaxS, or

If you are not using setpoint scaling and

0 > setpoint SP > 16383,

then during the initial execution of the PID loop, this error

occurs and bit 11 of word 0 of the control block is set.

However, during subsequent execution of the PID loop if an

invalid loop setpoint is entered, the PID loop continues to

execute using the old setpoint, and bit 11 of word 0 of the

control block is set.

If you are using setpoint scaling, then change

the setpoint SP to MinS <

SP < MaxS, or

If you are not using setpoint scaling, then change

the setpoint SP to 0 <

SP < 16383.

41H Scaling Selected Scaling Deselected Scaling Selected Scaling Deselected

1. Deadband < 0, or 1. Deadband < 0, or Change deadband to

0 <

deadband <

(MaxS - MinS) <

16383

Change deadband to

0 <

deadband < 16383

2. Deadband

>

(MaxS – MinS)

3. Deadband > 16383

51H 1. Output high limit < 0, or

2. Output high limit > 100

Change output high limit to

0 <

output high limit < 100

52H 1. Output low limit < 0, or

2. Output low limit > 100

Change output low limit to

0 <

output low limit < output high limit < 100

53H Output low limit > output high limit Change output low limit to

0 <

output low limit < output high limit < 100

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Loading...

Loading...