MAINTENANCE

Maintenance Schedule

After First 5 Hours

• Change Engine Oil

Every 8 Hours or Daily

• Check Engine Oil Level

• Clean Muffler, Rewind Starter Finger Guard, and Controls

Every 25 Hours or Annually

• Clean Air Filter and Pre-Cleaner †

Every 50 Hours or Annually

• Change Engine Oil

• Clean/Inspect Muffler and Spark Arrester

Every 100 Hours or Annually

• Change 6:1 Gear Reduction Oil (If Equipped)

Annually

• Replace Air Filter and Pre-Cleaner

• Clean/Gap/Replace Spark Plug

• Clean/Replace In-Tank Fuel Filter

• Clean Carburetor Sediment Bowl

• Clean Air Cooling System †

• Check/Adjust Valve Clearance ‡

† Clean more often in dusty conditions or when airborne debris is

present.

‡ Not required unless engine performance problems are noted.

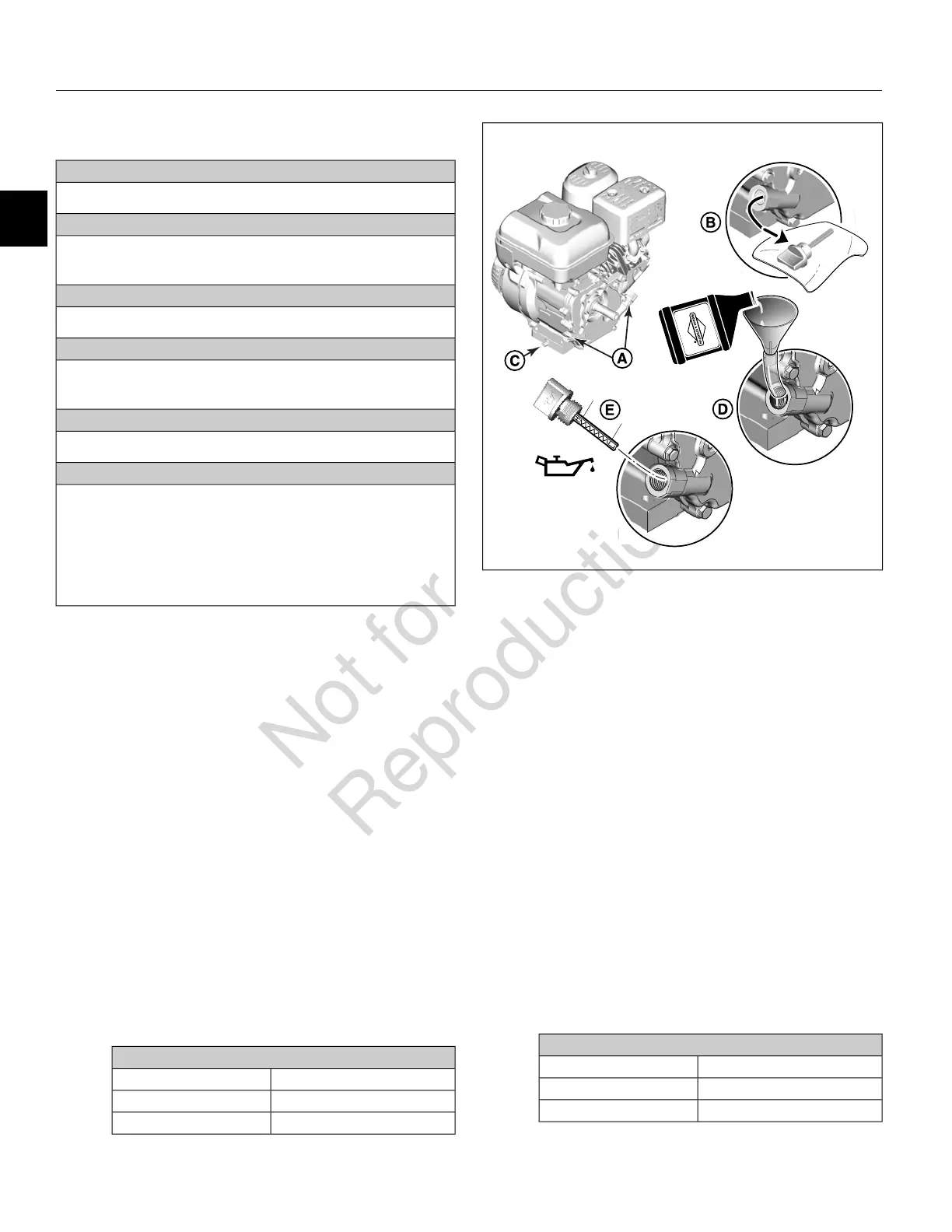

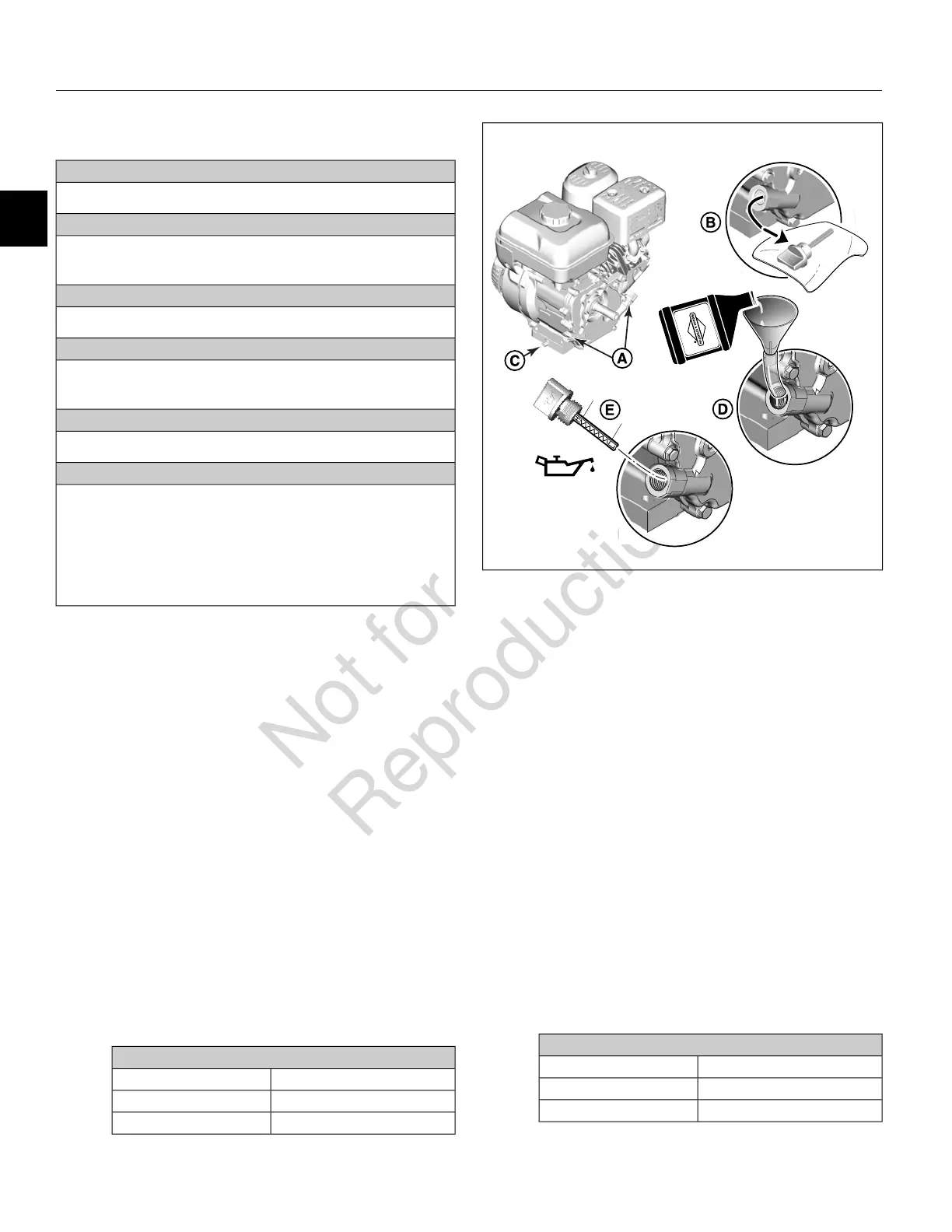

Change Engine Oil/Check Engine Oil Level

1. Place engine on a flat, level surface.

2. Remove spark plug wire from spark plug terminal.

Secure spark plug wire to prevent unintentional contact

with spark plug terminal.

3. See Figure 2. Thoroughly clean area around dipstick

oil plug (A) of all dirt and debris.

4. Remove dipstick oil plug and wipe dipstick with a clean,

lint free cloth (B).

NOTE: Proceed to step 8 if only checking engine oil

level.

5. Remove oil drain plug(s) with sealing washer(s) at base

of engine (C) and drain oil into an approved container.

6. Install oil drain plug(s) with sealing washer(s) and

tighten as follows.

Oil Drain Plug

TorqueModels

140-200 lb-in (15.8-22.6 N-m)130G00, 131G00, 13R200

248-266 lb-in (28-30 N-m)13U100, 13U200

2

7. Using a funnel and a short length of plastic tubing,

slowly pour 19-22 ounces (550-650 ml) of the

recommended type of oil into the oil plug opening (D).

See

Section 1 - Safety and General Information,

General Information, Oil Recommendations.

DO NOT

overfill.

8. Slowly insert dipstick oil plug until lightly seated on

threads, but do not tighten.

NOTE: The most accurate oil level readings are

obtained when the engine is cold.

9. Allow a few seconds to elapse, and then slowly remove

dipstick oil plug.

10. Verify that oil level (E) is on the cross hatch pattern at

or near the H(igh) mark.

NOTE: Observe oil level on both sides of the dipstick.

The lower level of the two readings is the correct oil

level measurement.

11. Add oil as necessary until oil level is correct.

12. Install dipstick oil plug and tighten as follows.

Dipstick Oil Plug

TorqueModels

10-30 lb-in (1.1-3.4 N-m)130G00, 131G00, 13R200

18-27 lb-in (2-3 N-m)13U100, 13U200

10

2

Loading...

Loading...