Stamped/Wire Guard Spark Arrester Screw(s)

TorqueModels

71-124 lb-in (8-14 N-m)130G00, 131G00, 13R200

27-44 lb-in (3-5 N-m)13U100, 13U200

NOTE: Spark arrester is installed in either the 9 o'clock

or the optional 6 o'clock position.

Change 6:1 Gear Reduction Oil (If Equipped)

1. Remove spark plug wire from spark plug terminal.

Secure spark plug wire to prevent unintentional contact

with spark plug terminal.

2. Place engine on a flat, level surface.

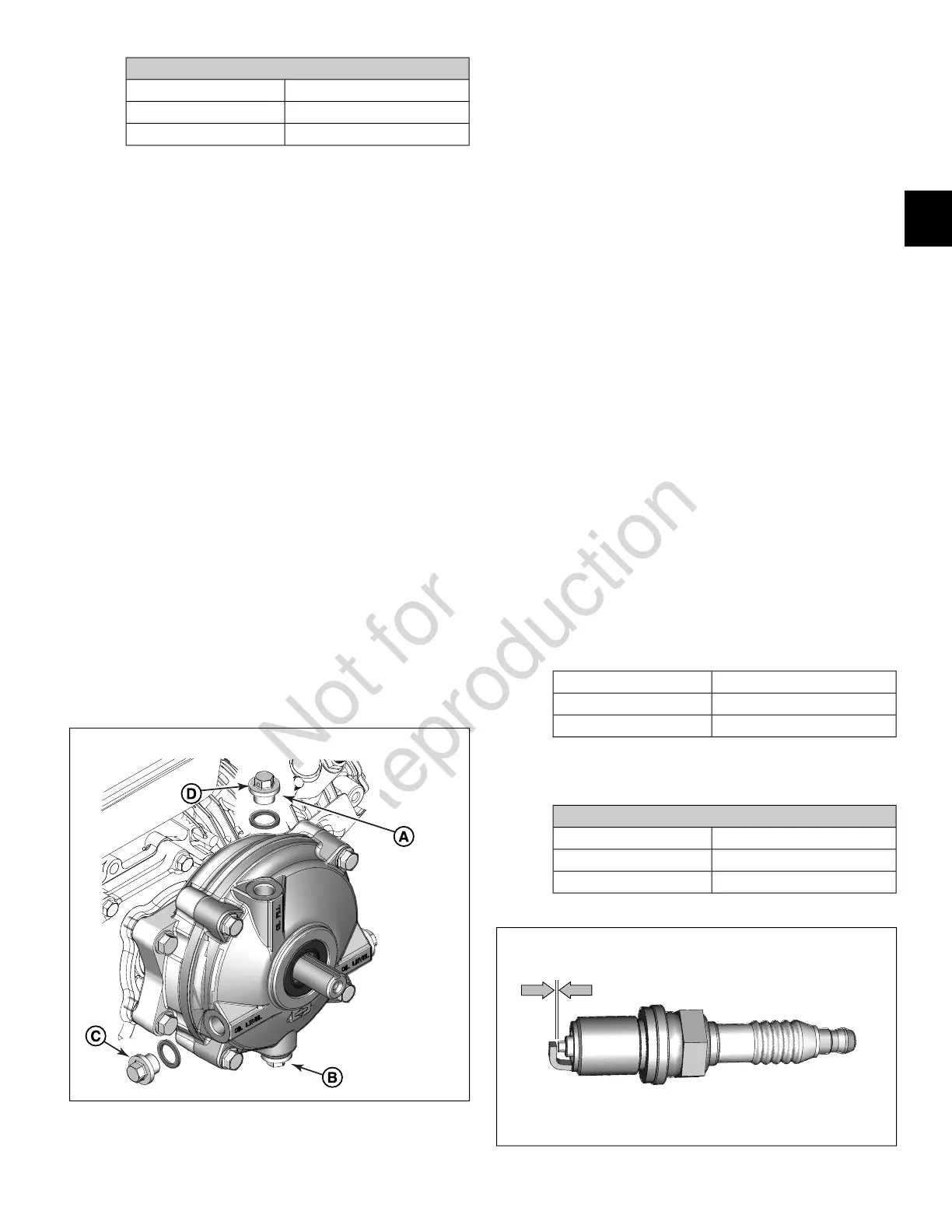

3. See Figure 9. Remove oil fill/vent plug (A) with sealing

washer from the gear case cover.

4. Remove oil drain plug (B) with sealing washer and drain

oil into an approved container.

5. Install oil drain plug with sealing washer and tighten to

180-210 lb-in (20.3-23.7 N-m).

6. Remove oil level plug (C) with sealing washer.

7. Slowly add the appropriate oil into the oil fill hole until

oil begins to run out of the oil level hole (approximately

4 ounces).

• Use SAE 80W-90 above 40° F (10° C)

• Use SAE 10W-30 below 40° F (10° C)

8. Install oil level plug with sealing washer. Install oil

fill/vent plug with copper washer. Tighten each plug to

180-210 lb-in (20.3-23.7 N-m).

9

NOTE: Verify that vent hole (D) of oil fill/vent plug is

facing outside.

9. Dispose of used oil at a proper waste disposal or

recycling center.

Clean/Gap/Replace Spark Plug

NOTE: Spark plugs have different thread lengths and heat

ranges. Always use the specified replacement spark plug

or engine damage can occur.

NOTE: Some localities require use of a special resistor type

spark plug to suppress ignition noise. If the engine was

originally equipped with a resistor type spark plug, be sure

to use the same replacement spark plug.

1. Remove spark plug wire from spark plug terminal.

2. Thoroughly clean area around spark plug to keep dirt

and debris out of combustion chamber.

3. Remove spark plug from cylinder head using the 5/8

inch Spark Plug Wrench (Part No. 19576S).

4. Check condition of threads in cylinder head. If

necessary, soften deposits with penetrating oil and

clean out with a thread chaser.

5. Clean spark plug using a wire brush and commercial

solvent. Do not bead blast spark plug. Obtain new spark

plug if electrode is pitted or burned, or if porcelain is

cracked.

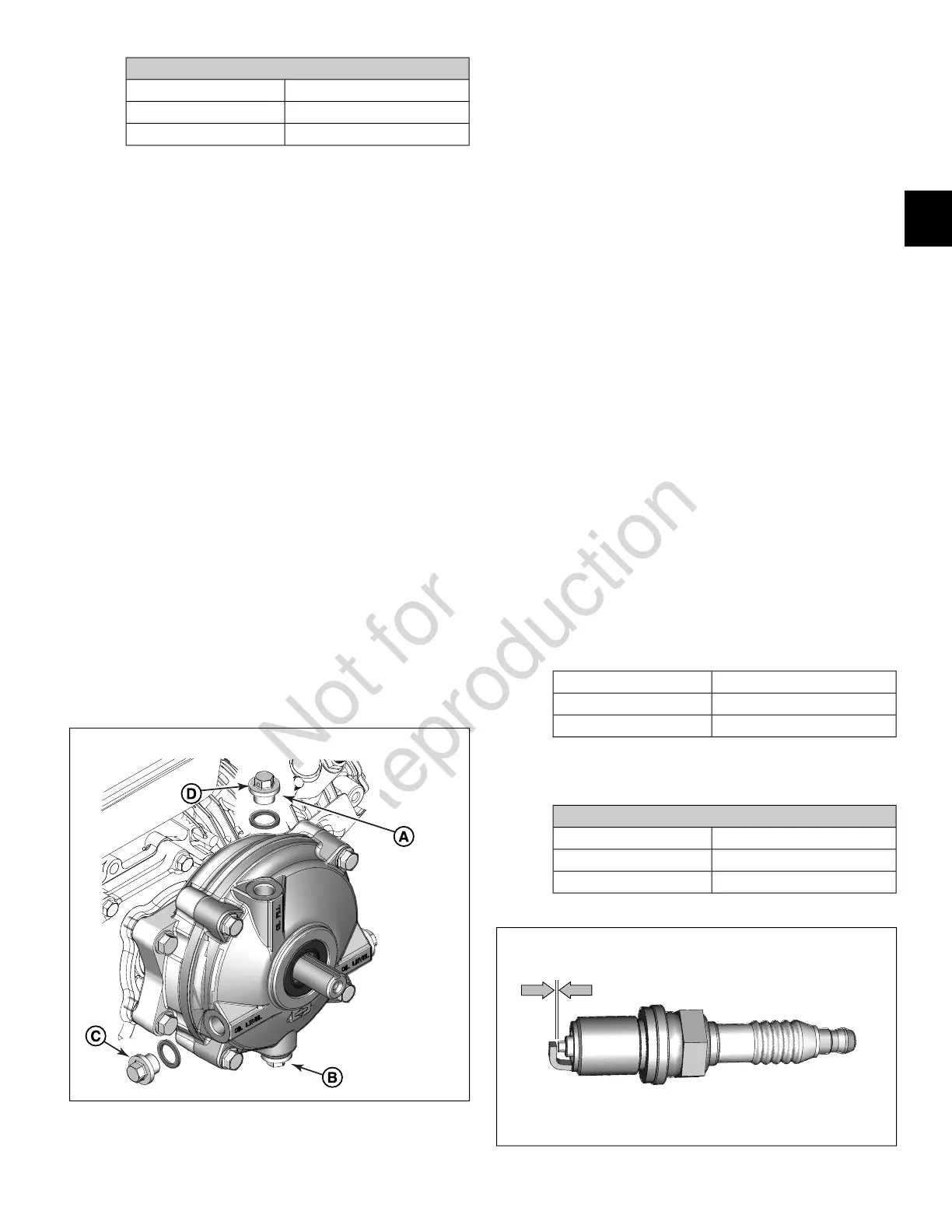

6. See Figure 10. Using a feeler gauge, verify spark plug

gap is as follows. If necessary, adjust gap by carefully

bending ground electrode.

Spark Plug GapModels

0.027-0.033 in (0.69-0.83 mm)130G00, 131G00, 13R200

0.028-0.035 in (0.70-0.90 mm)13U100, 13U200

7. Finger tighten spark plug into cylinder head, and then

tighten as follows.

Spark Plug

TorqueModels

140-200 lb-in (15.8-22.6 N-m)130G00, 131G00, 13R200

230-319 lb-in (26-36 N-m)13U100, 13U200

10

15

2

Loading...

Loading...