cleanliness. Do not use a wire brush or the holes may

be enlarged.

7. If present, verify that set of oil drain back holes at top

of piston skirt are clean and open.

Connecting Rod

1. Thoroughly clean parts in a non-volatile cleaning

solution or solvent. Follow up with a thorough wash in

hot soapy water.

2. Blow dry with low pressure compressed air.

3. Verify that oil holes in connecting rod shank and at top

of piston pin bore are clean and open.

Inspection

Piston and Pin

1. Carefully inspect the piston for damage or excessive

wear. Proceed as follows:

A. Inspect the piston for cracks. Pay special attention

to the area around the pin bores and oil drain back

holes beneath the piston crown.

B. Check piston for cracked, broken or bent ring lands.

C. Check piston skirt for cracks, gouges, deep

scratches or heavy scoring.

D. Check piston head for evidence of burning, etching

or melting.

E. Look for marks or imprints caused by contact with

valves.

NOTE: A piston with superficial wear marks, minor

scratching or mild scoring may continue to be used.

2. Lightly oil a good piston pin and insert it into the piston

pin bore to feel for proper fitment. The pin should slide

in and out without binding, but also without pivoting or

rocking.

60

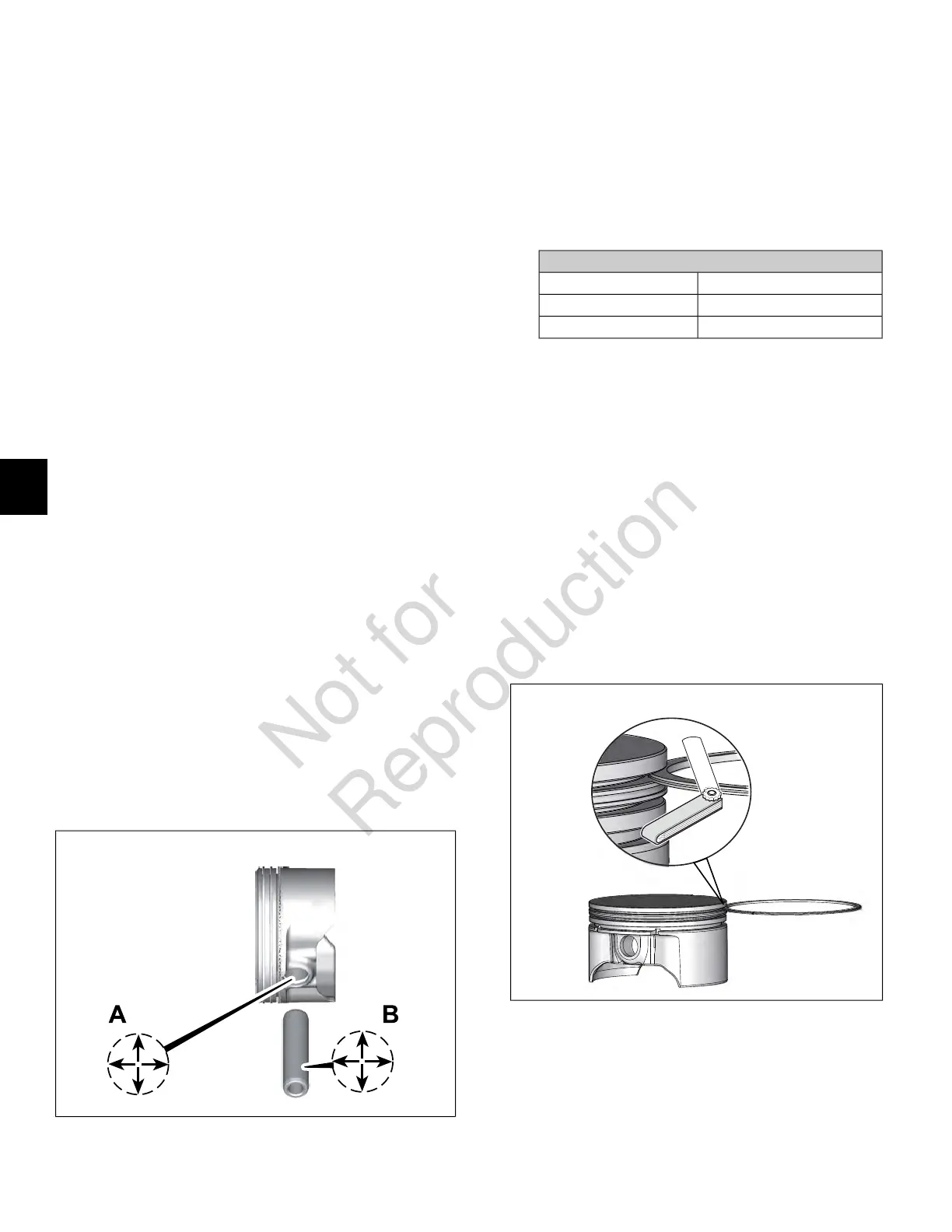

3. See A of Figure 60. Using an inside micrometer or dial

vernier caliper, measure the piston pin bore diameter

at two locations- parallel and perpendicular to the

crankshaft. Replace the piston if either measurement

is 0.711 inches (18.06 mm) or more.

4. See B of Figure 60. Using an outside micrometer,

measure the outside diameter of the piston pin at two

locations- parallel and perpendicular to the crankshaft.

Replace piston pin if either measurement is at the reject

size shown below.

Piston Pin Diameter

Reject SizeModels

0.707 in (17.96 mm) or less130G00, 131G00, 13R200

0.708 in (17.97 mm) or less13U100, 13U200

5. Run your index finger around the edge of the piston

crown to feel for dings, nicks or burrs. Lightly file the

edge of the crown to remove any defects.

6. Measure the piston ring side clearance as follows:

NOTE: Worn ring grooves result in high oil consumption

and blow-by of exhaust gases. Blow-by of exhaust

gases contaminates the engine oil supply, and reduces

engine efficiency by weakening the combustion seal

necessary for efficient transfer of energy to the piston.

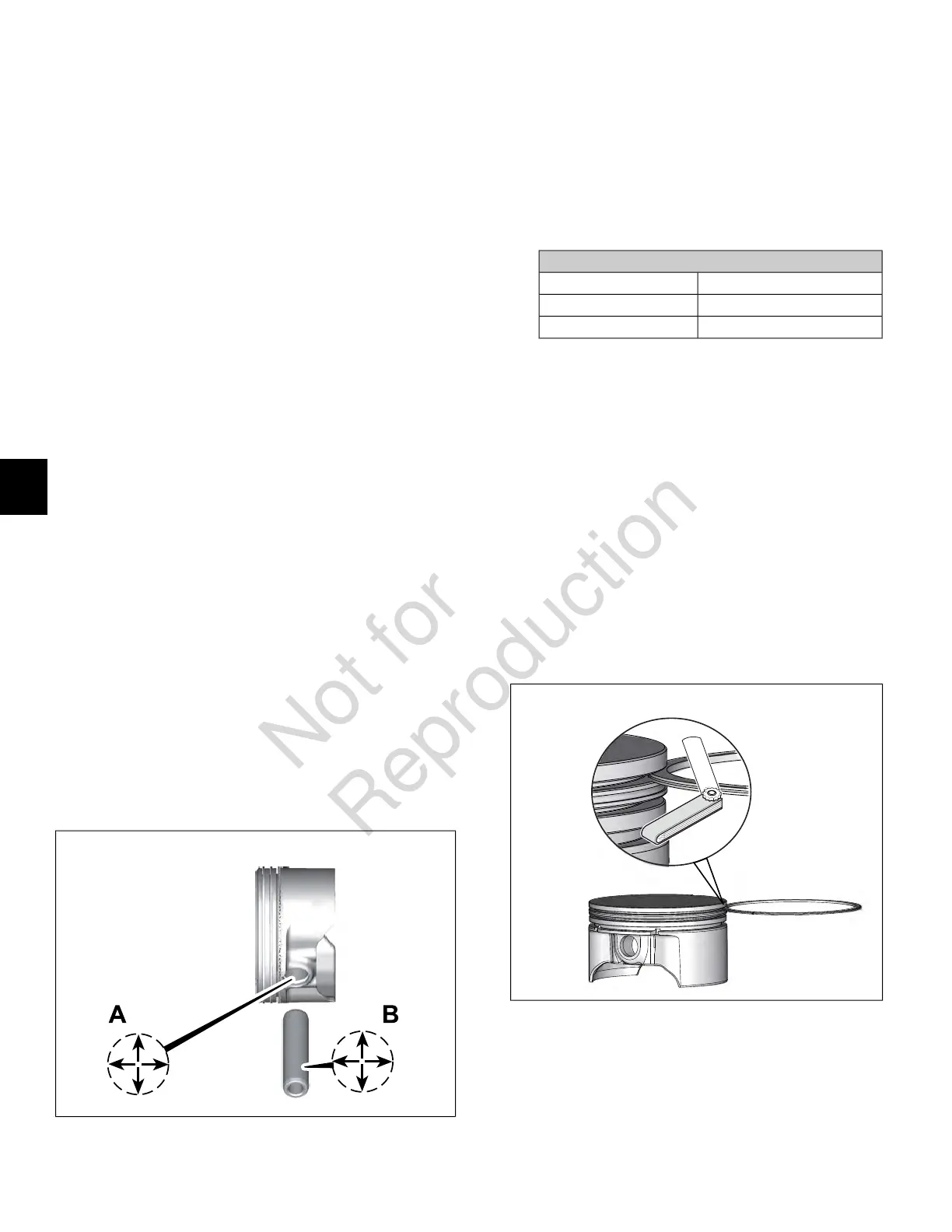

A. See Figure 61. Insert the edge of a new

compression ring into the top piston ring groove.

Insert a feeler gauge between the upper surface of

the ring and the ring land.

61

B. Since the grooves wear unevenly, repeat this check

at several locations around the piston ring groove

circumference.

C. Discard the piston if any measurement is 0.009

inches (0.23 mm) or more.

54

6

Loading...

Loading...