Starter Motor (If Equipped)

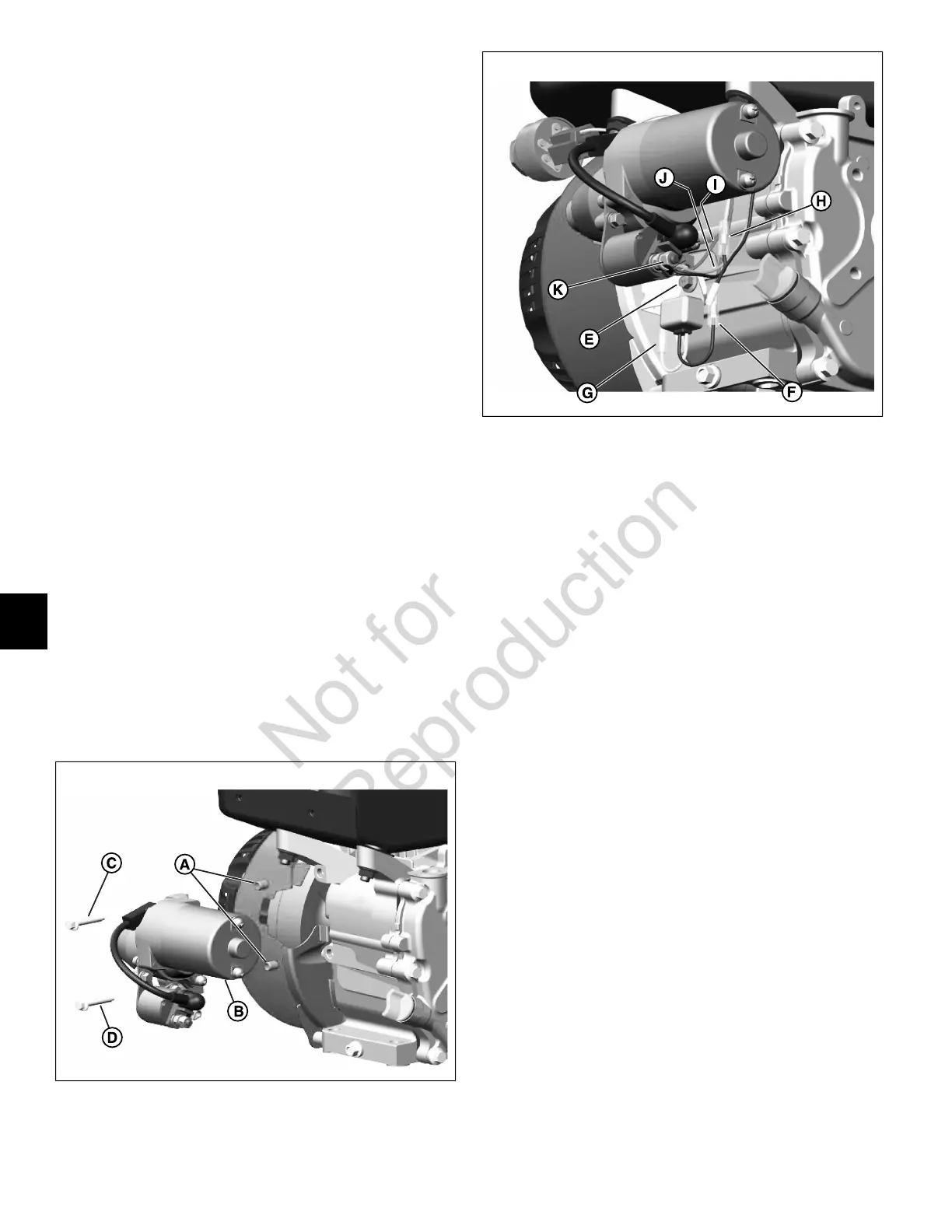

1. Install connector and spade terminal to key switch on

trim panel.

2. See Figure 125. Install two locating pins (A) into holes

in crankcase.

3. With the stator wires routed over the top of the starter

motor, install starter motor (B) onto locating pins.

4. Install top starter motor screw (C) capturing brown key

switch ground wire ring terminal, and tighten to 80-110

lb-in (9-12.4 N-m).

5. Install bottom starter motor screw (D) and tighten to

80-110 lb-in (9-12.4 N-m).

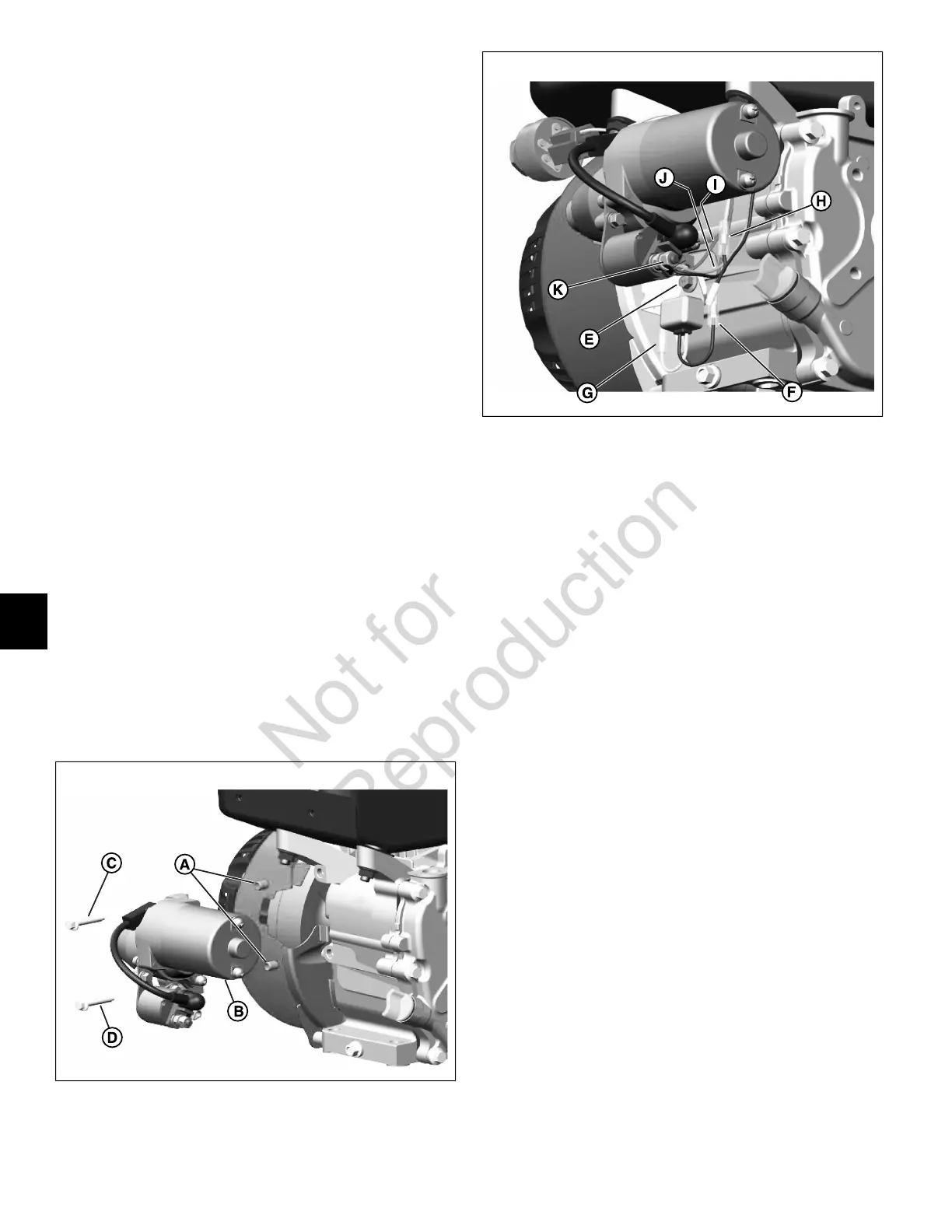

6. See Figure 126. If equipped, install low oil sensor

module as follows:

A. Install hex flange screw (E) to fasten oil sensor

module bracket to flywheel guard. Tighten screw

to 30-80 lb-in (3.4-9 N-m).

B. Connect one-place wire connector (F) between oil

sensor module and key switch spade contact.

C. Connect one-place wire connector (G) between oil

sensor module and oil sensor.

7. Route yellow key switch wire and orange key switch

wire behind starter motor to area of starter solenoid.

8. Connect yellow key switch wire terminal to starter

solenoid black wire terminal (H).

9. If stator wires terminate in a ring terminal, move to step

10. If stator wires terminate in a 2-place jumper wire

connector, proceed as follows:

NOTE: Ring terminal supersedes 2-place jumper wire

connector on late model engines.

125

126

A. Install flat washer and red jumper wire (I) ring

terminal onto starter solenoid post.

B. Coil extra length of jumper wire behind starter

motor.

C. Connect 2-place jumper wire connector between

stator and starter solenoid post.

D. Move to step 11.

10. Install flat washer and red stator wire ring terminal (I)

onto starter solenoid post.

11. Install orange key switch wire ring terminal (J) onto

starter solenoid post.

12. Install flat washer, lock washer, and hex nut (K) onto

starter solenoid post. Tighten hex nut to 30-40 lb-in

(3.4-4.5 N-m).

86

8

Loading...

Loading...