NOTE: If stud is difficult to remove, apply suitable

penetrating oil to threads, and then work stud in

and out until it moves freely.

E. Remove stud from cylinder head. Remove hex

flange nuts from stud.

F. Install new stud, so that the stepped side goes into

the cylinder head.

G. Repeats steps 2(B) and 2(C).

H. Rotating outside nut in a clockwise direction, tighten

stud as follows.

Carburetor Stud

TorqueModels

50-70 in-lbs (5.7-7.9 N-m)130G00, 131G00, 13R200

44-62 lb-in (5-7 N-m)13U100, 13U200

3. Replace a muffler stud as follows:

A. Retrieve the two hex nuts removed from the studs

during muffler removal.

B. Thread first nut onto stud.

C. Thread second nut onto stud until it makes firm

contact with the first.

D. Rotate inside nut in a counter-clockwise direction

until stud is loose.

NOTE: If stud is difficult to remove, apply suitable

penetrating oil to threads, and then work stud in

and out until it moves freely.

E. Remove stud from cylinder head. Remove hex nuts

from stud.

F. Install new stud, so that the side with the shorter

threads goes into the cylinder head.

G. Repeats steps 3(B) and 3(C).

H. Rotating outside nut in a clockwise direction, tighten

stud as follows.

Muffler Stud

TorqueModels

40-60 in-lbs (4.5-6.8 N-m)130G00, 131G00, 13R200

35-62 lb-in (4-7 N-m)13U100, 13U200

Assembly

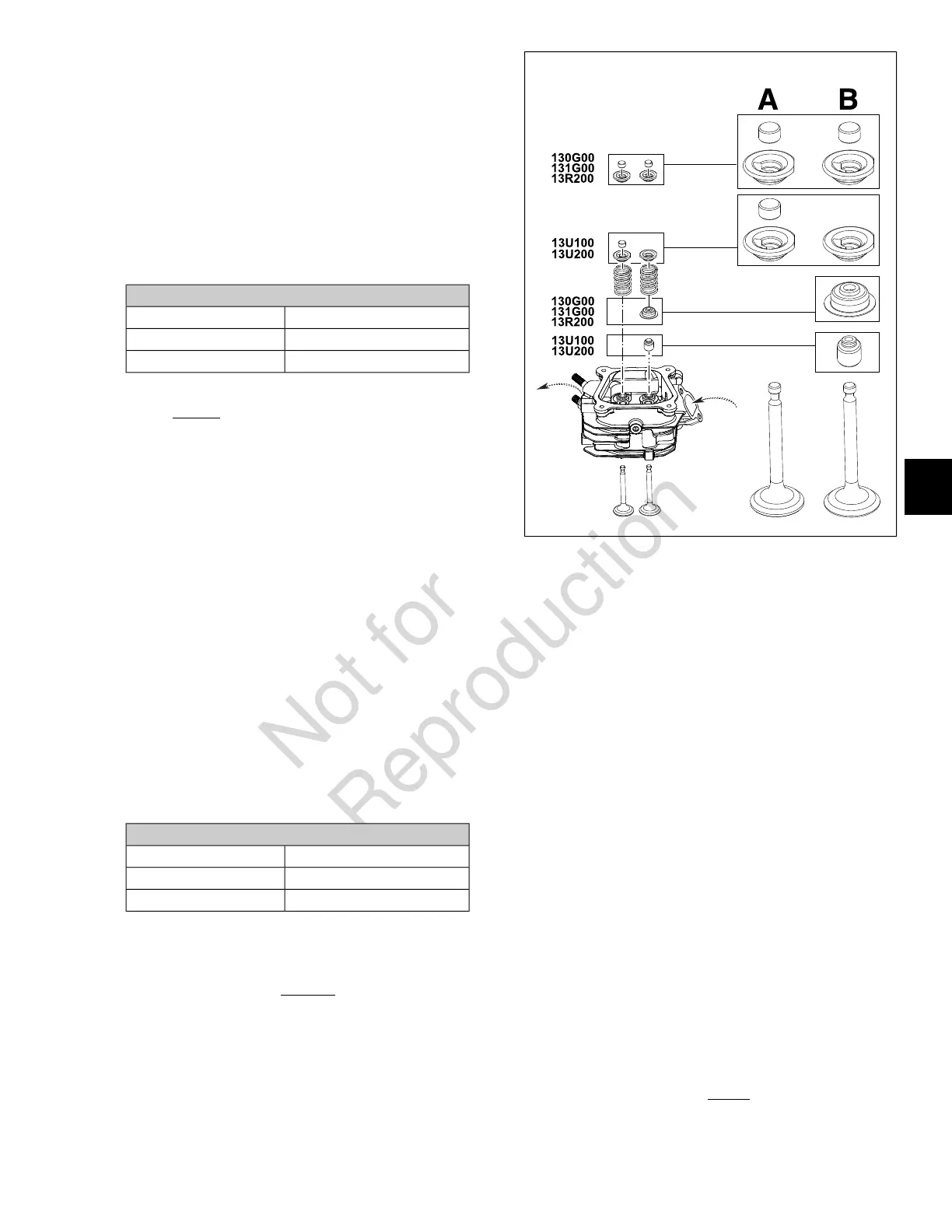

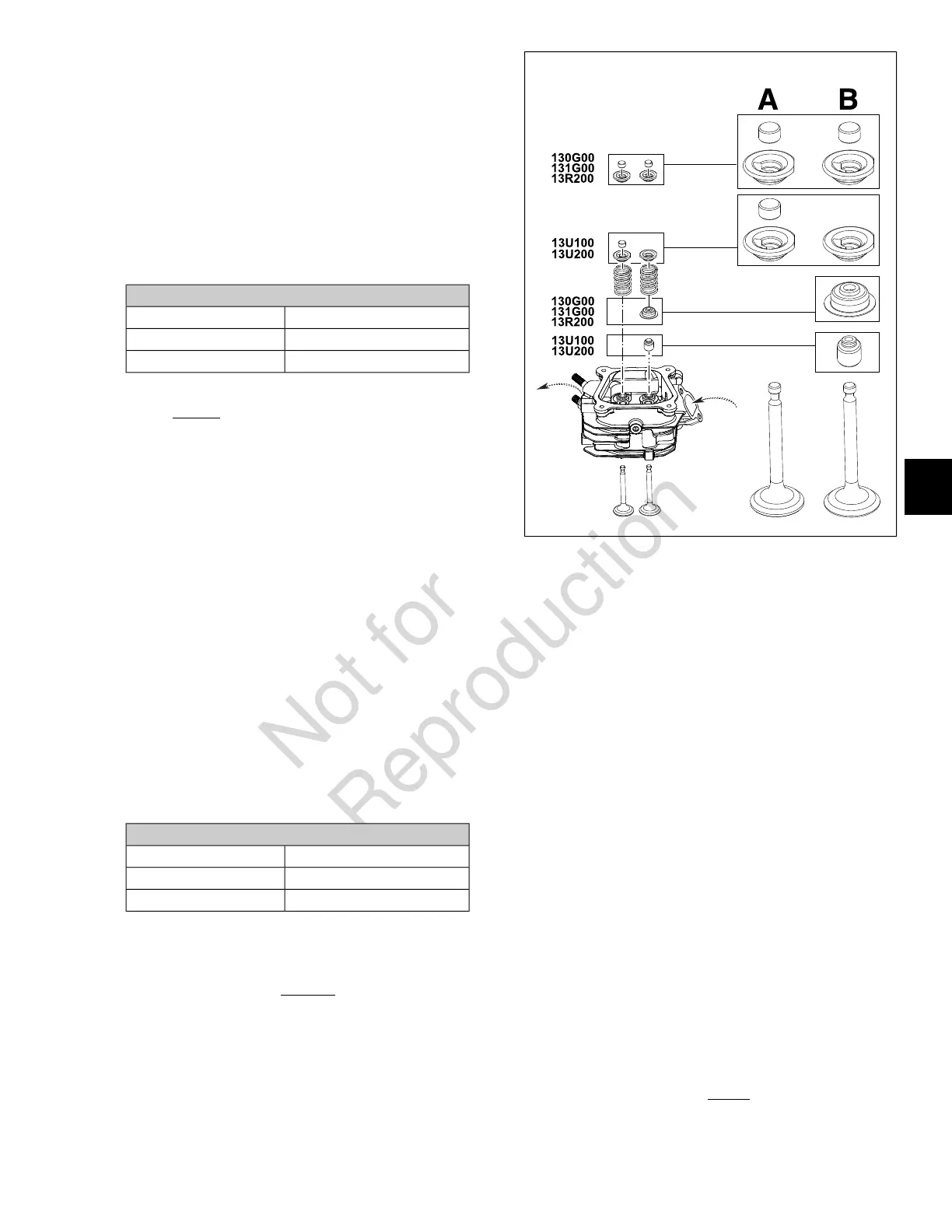

1. See A of Figure 57. Install exhaust valve assembly as

follows:

A. Apply a suitable engine assembly lube to the valve

stem.

NOTE: If the valves were not tagged during

disassembly, remember that the exhaust valve

always has the smaller valve face diameter.

57

B. From the bottom of the cylinder head, insert the

valve stem into the valve guide.

C. To distribute the assembly lube evenly around the

valve stem and guide, hand spin the valve as it is

installed. Work the valve back and forth in the bore

to verify that it slides smoothly and seats properly.

D. Using denatured alcohol or other suitable

degreaser, thoroughly clean valve face, valve seat,

valve guide, and end of valve stem of any excess

assembly lube.

E. Install valve spring over the valve stem and valve

guide.

F. Set the valve spring retainer on top of the valve

spring. Using thumbs to compress valve spring,

guide the end of the valve stem through the larger

offset hole in the valve spring retainer. Continue

pressing down until the smaller center hole engages

the valve stem groove.

G. Verify that the axis of the valve spring is parallel to

the valve stem. A cocked valve spring will result in

premature valve guide wear.

H. Lightly tap the end of the valve stem once or twice

with a soft mallet to ensure that valve spring retainer

is tightly seated in the valve stem groove.

I. Install valve cap on end of valve stem.

2. See B of Figure 57. Install intake valve assembly as

follows:

51

6

Loading...

Loading...