INSTALL EXTERNAL ASSEMBLIES

Armature

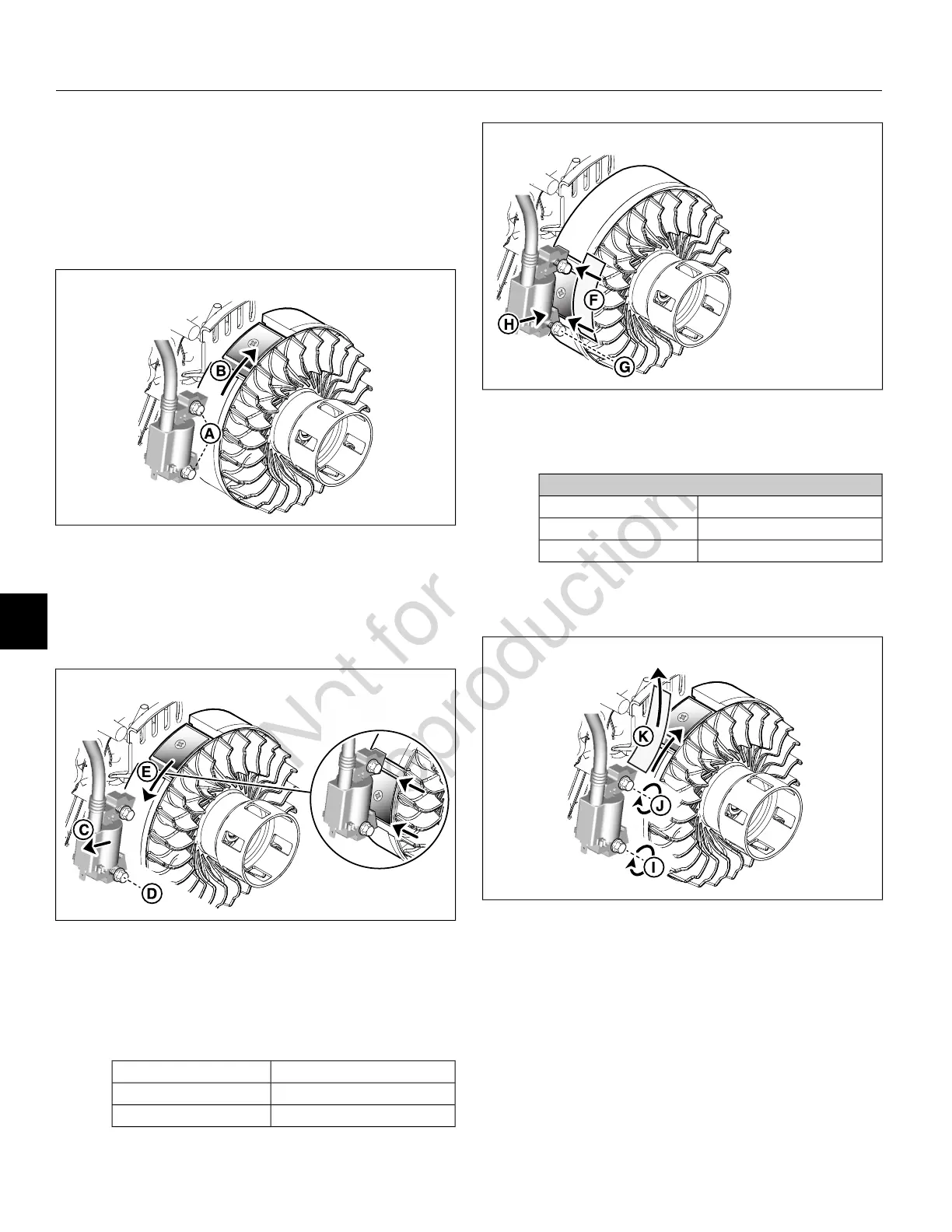

1. See Figure 105. Loosely install two hex flange screws

(A) to fasten armature to crankcase.

2. Rotate flywheel to move magnet away from armature

legs (B).

105

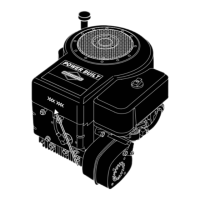

3. See Figure 106. Slide armature (C) away from flywheel.

4. Tighten bottom hex flange screw (D) until snug.

5. Rotate flywheel, so that magnet is aligned with armature

legs (E).

106

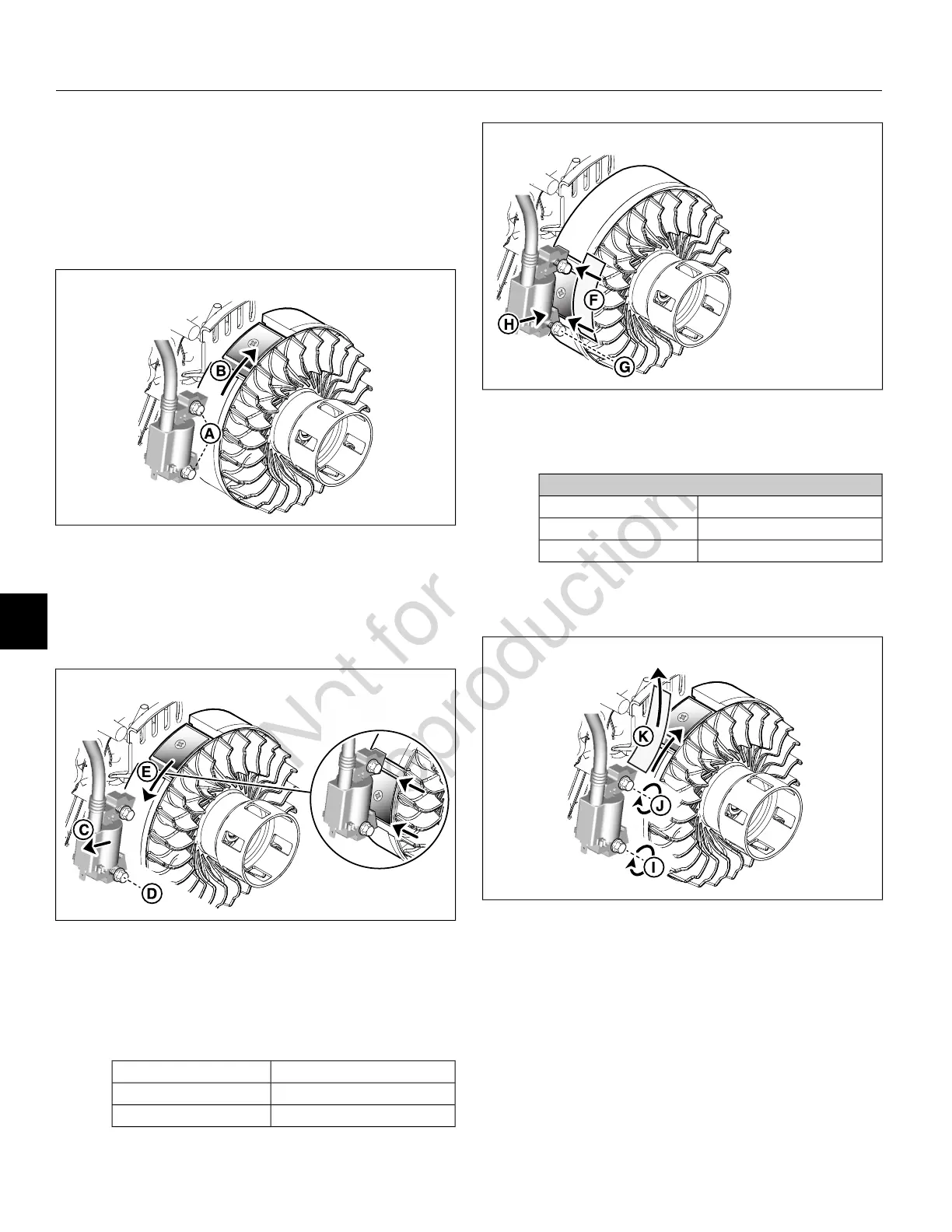

6. See Figure 107. Insert feeler gauge (F) or Armature Air

Gap Gauge (Part No. CE5121) between flywheel and

armature legs. Loosen bottom hex flange screw (G)

and push armature legs (H) tight against gauge to set

air gap as follows.

Armature Air GapModels

0.010-0.014 in (0.25-0.35 mm)130G00, 131G00, 13R200

0.008-0.016 in (0.20-0.40 mm)13U100, 13U200

107

7. See Figure 108. Tighten bottom hex flange screw (I)

and then top hex flange screw (J) as follows.

Armature Screws

TorqueModels

80-110 lb-in (9-12.4 N-m)130G00, 131G00, 13R200

71-124 lb-in (8-14 N-m)13U100, 13U200

8. Rotate flywheel to remove gauge (K).

108

9. See Figure 109. Route remote magneto stop terminal

wire between ribs at top of crankcase. First pull wire

tight and then push down firmly, so that it is snugly

seated against casting. Capture wire in clip on flywheel

guard.

NOTE: Through contact with governor lever, link, or

springs, loose wires can interfere with governor

operation.

76

8

Loading...

Loading...