XNX Universal Transmitter

Section 3 - Calibration

105

Using the Calibration Cup

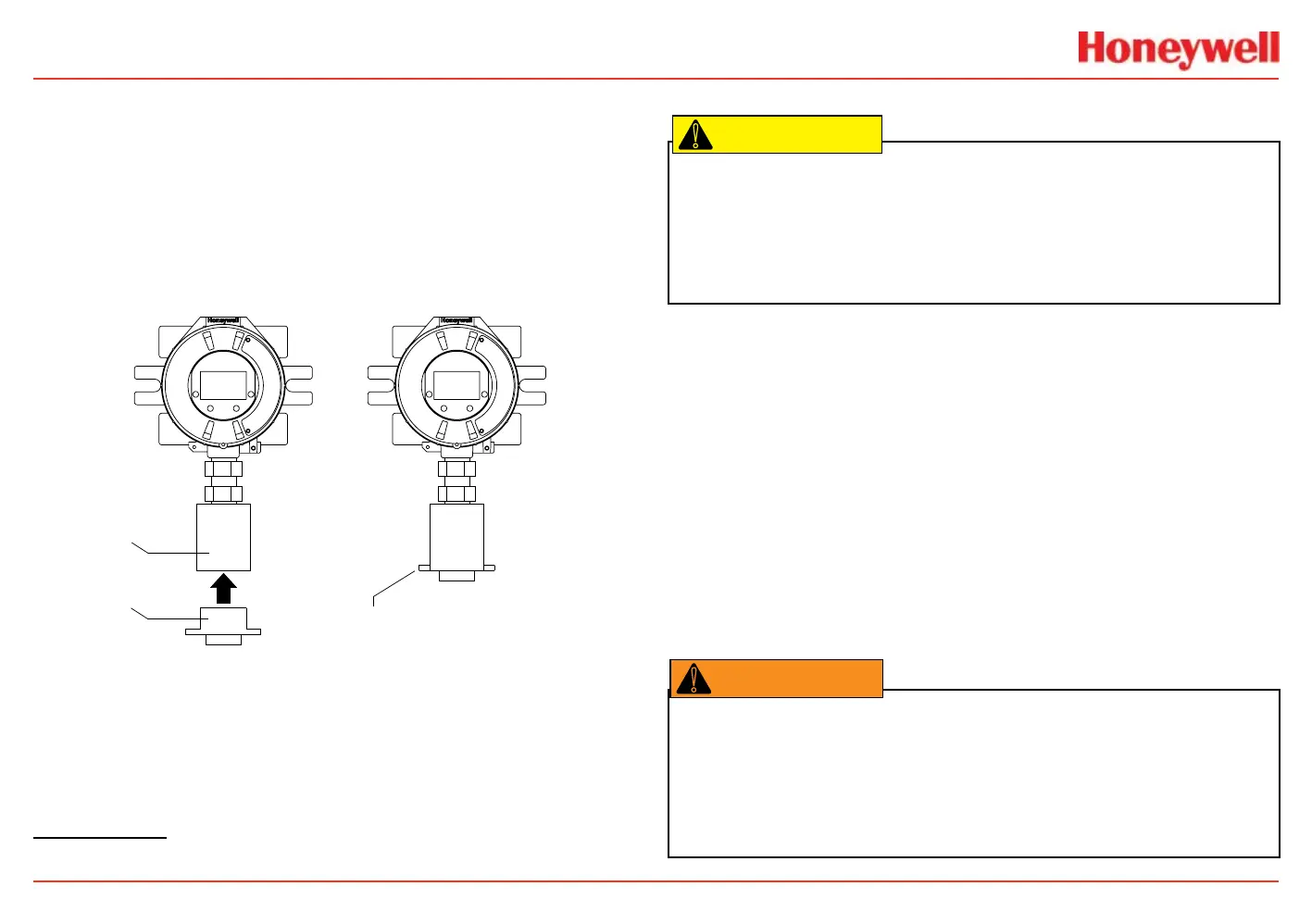

Refer to Figure 202 to attach the calibration cup:

1. Snap the calibration cup into the weather protector. The two

protrusions on the cup t into recesses in the weather protector.

2. Attach the hose from the gas cylinder to the calibration cup. Note

that the cup’s ow is unidirectional. There is an arrow on the

bottom showing ow direction

3. Adjust the calibration ow rate

1

.

weather

protector

calibration cup

attach gas

cylinder hose

Figure 202. Attaching the Calibration Cup

1 300-375 ml/min for XNX EC sensors, 300-700 ml/min for XNX mV sensors, unless other-

wise directed.

Zero and Span Calibration of EC Sensors

Caution: Before initial calibration, allow the sensor to stabilize for 30 minutes after applying power.

When in zero and span calibration modes, the current output from the sensor is inhibited (default

2mA) to avoid false alarms.

Caution: Recalibrate if the temperature of local environment has varied by more than ±15°C from

the temperature of calibration.

!

Hydrogen Sulde

Hydrogen Sulde sensors can be affected by extreme humidity

changes. A sudden increase in ambient humidity can result in a short-

term positive drift in the instrument’s reading. A sudden decrease

in ambient humidity can result in a short-term negative drift in the

instrument’s reading. These are most likely to be noticed during

calibration with dry or cylinder gas.

When calibrating hydrogen sulde cartridges, follow the procedure

in Calibration Procedure. To zero the sensor, use a compressed gas

cylinder of 20.9%Vol oxygen (not nitrogen). Do not use background air.

If a span calibration is to be performed, apply the span calibration gas

immediately after the zeroing procedure. Do not allow the sensor to

return to ambient air conditions.

Warning: Long-term exposure (>20 minutes) to concentrations exceediing the full-scale range of

the H

2

S sensor Type 2 can cause it to lose sensitivity. The measured value may then decrease

even though high levels of toxic gas are still present. If such conditions can occur, set the control unit

to latch at overrange. In standalone operation, set alarms to latching. When resetting the overrange

or alarm, verify the correct operation of the transmitter. Before re-calibrating the transmitter, verify

the absence of gas.

Loading...

Loading...