Troubleshooting Guide

Powermax45 XP Operator Manual 809240 145

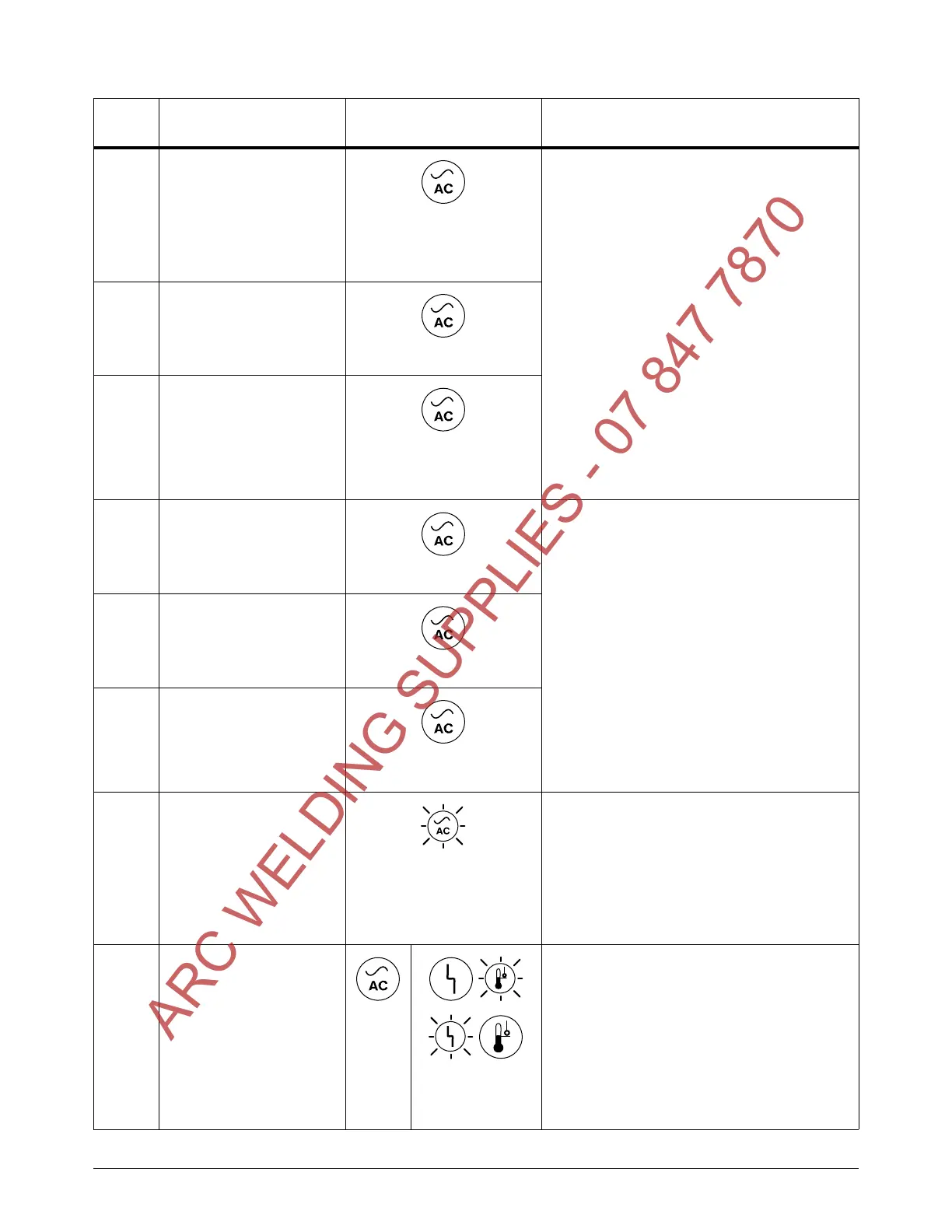

0-11-0 Remote controller mode

invalid. Valid remote

modes for this system:

• 1, 2 – Continuous

pilot arc

•3–Gouge

ON

There is a problem with the remote controller

or the software interface to the system. The

system cannot interpret the mode, output

current, or gas pressure information coming

from the controller.

• Fix the controller.

• Check the RS-485 interface cable.

• Examine the programming code for

incorrect process variables.

0-11-1 Remote controller current

invalid. Valid remote

current settings for this

system: 10 – 45 A.

ON

0-11-2 Remote controller

pressure invalid. Valid

remote pressure settings

for this system depend on

the process, mode, torch,

and torch lead.

ON

0-12-1 Output gas pressure low

ON

The 0-12-n fault codes do not appear on the

2-digit display. They display only on a CNC via

an RS-485 serial interface. An 0-12-n fault

does not stop the system from operating.

• Adjust the gas inlet pressure as needed.

• Make sure none of the gas lines are

kinked or blocked.

• Run a gas test to see if the actual

pressure is lower or higher than the set

pressure. See Run a gas test on

page 149.

• Have a qualified service technician

examine the system. Contact your

distributor or authorized repair facility.

0-12-2 Output gas pressure high

ON

0-12-3 Output gas pressure

unstable

ON

0-13-0 Alternating current (AC)

input power unstable

(system continues to

operate)

Blinks

• Perform a cold restart.

• If applicable, disconnect the system from

generator power. See Generator

considerations on page 149.

• If the fault does not clear, have an

electrical technician correct the power

source. Seepage27.

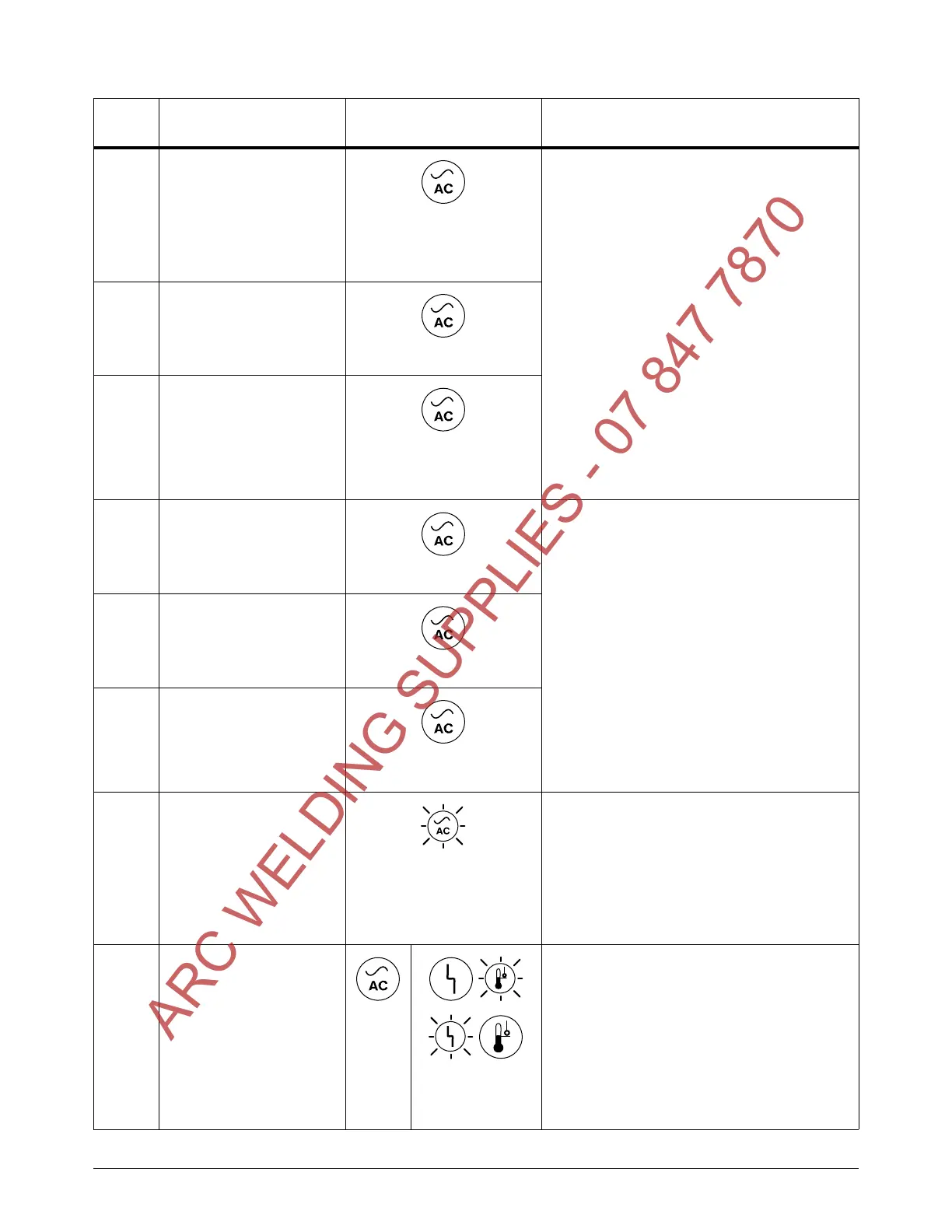

0-51-0 Start/trigger signal on at

power up

This condition indicates

that the power supply is

receiving a start signal. It

is sometimes referred to

as a “stuck start.”

ON

Blinks alternately

• Hand torch: The torch trigger was being

held in the “fire” position while the plasma

power supply was being powered ON (I).

Release the trigger and restart the power

supply.

• Machine torch: The plasma power supply

was receiving a start signal when it was

powered ON (I). Turn off the start signal

and restart the power supply.

Fault

code

Description LED behavior Solutions

ARC WELDING SUPPLIES - 07 847 7870

Loading...

Loading...