– 49 –

Switch/display Description

1

Manual switch A press on this switch increases the number of sewn pieces by one.

2

Product number selection switch This switch is used to display an abbreviated number for the selected prod-

uct number.

When this switch is pressed, the sewing product's product number input

screen is displayed. Refer to

"

#

-5-2. (2) Sewing product's product num-

ber input screen"

.

3

Operator ID selection switch This switch is used to display an abbreviated number for the selected op-

erator ID.

When this switch is pressed, the operator ID selection popup screen is dis-

played. Refer to

"

#

-5-2. (3) Operator ID selection screen"

.

4

Optional ID selection switch This switch is used to display an abbreviated number for the selected op-

tional ID.

When this switch is pressed, the optional ID selection screen is displayed.

Refer to

"

#

-5-2. (4) Optional ID selection screen"

.

5

No. of pcs. in lot setting switch In the case of the lot production, the number of pieces in a lot can be

counted collectively. The total number of pieces in a lot should be entered.

When this switch is pressed, the No. of pcs. in lot input screen is displayed.

Refer to

“

#

-5-2. (5) No. of pcs. in lot setting screen”

.

6

Measurement changeover switch This switch is used to stop measurement and recording of the sewing ma-

chine operation data.

* Measurement is carried out (state):

* Measurement is stopped: Sewing machine startup is stopped (state):

7

Communication selection switch This switch is used to upload measurement data.

When the switch is pressed, the communication selection screen is dis-

played. Refer to

"

#

-5-2. (6) Communication selection screen"

.

A

Display of the current time of day

The current time of day is displayed.

B Display of the latest pitch time The time period between two times of thread trimming is measured and

displayed.

C

Display of the production volume

The production volume under sewing work is displayed.

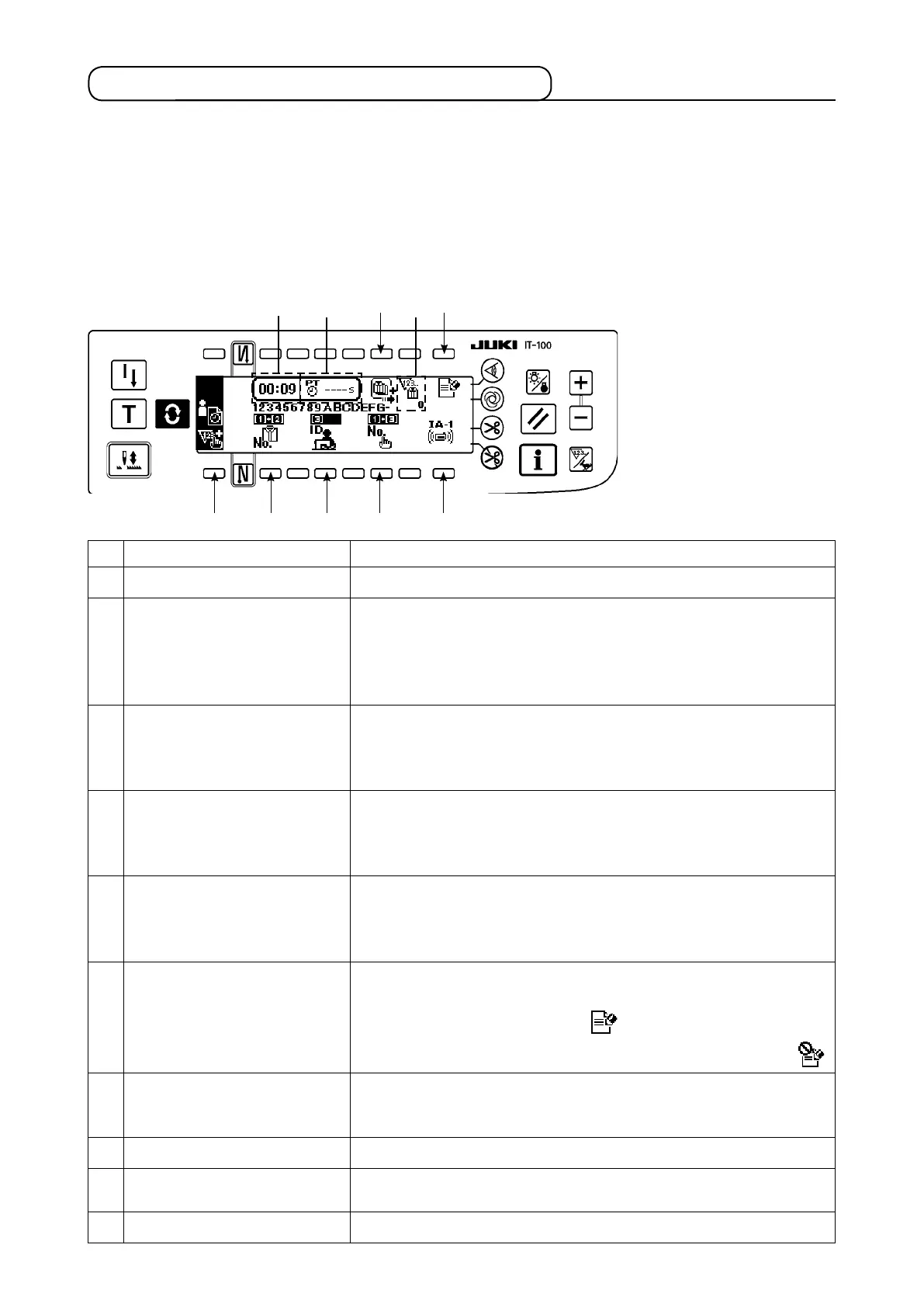

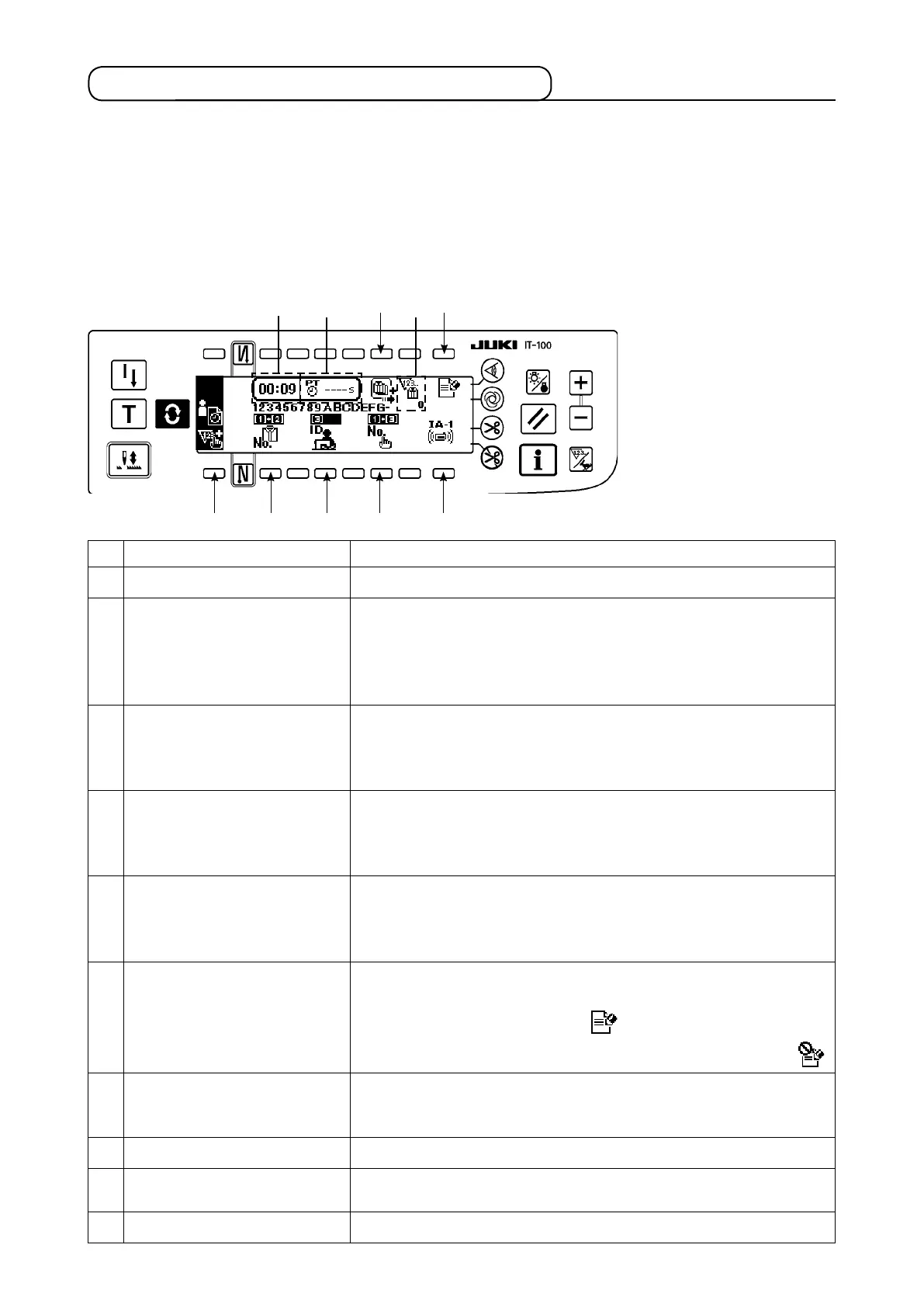

5-2. Operating the work management screen

1

6

4

5

2 3

7

A B C

(1) Work management screen

On the work management screen, work data such as the operator ID, product number and process number,

which are to be embedded in the operation data recorded by each sewing machine are entered and man-

aged. In addition, the recoded operation data can be uploaded. Furthermore, on the work management

screen, operations required for procedures such as count-up of the production volume and stopping of mea-

surement can be carried out. This means that sewing work can be done with this screen displayed.

*

Refer to "

#

. 5-1. How to change over the screen under the normal sewing mode" for the operating pro-

cedure to be taken until this screen is displayed.

Loading...

Loading...