AMS-210D, 210D P TYPE (September, 2003) 1/3

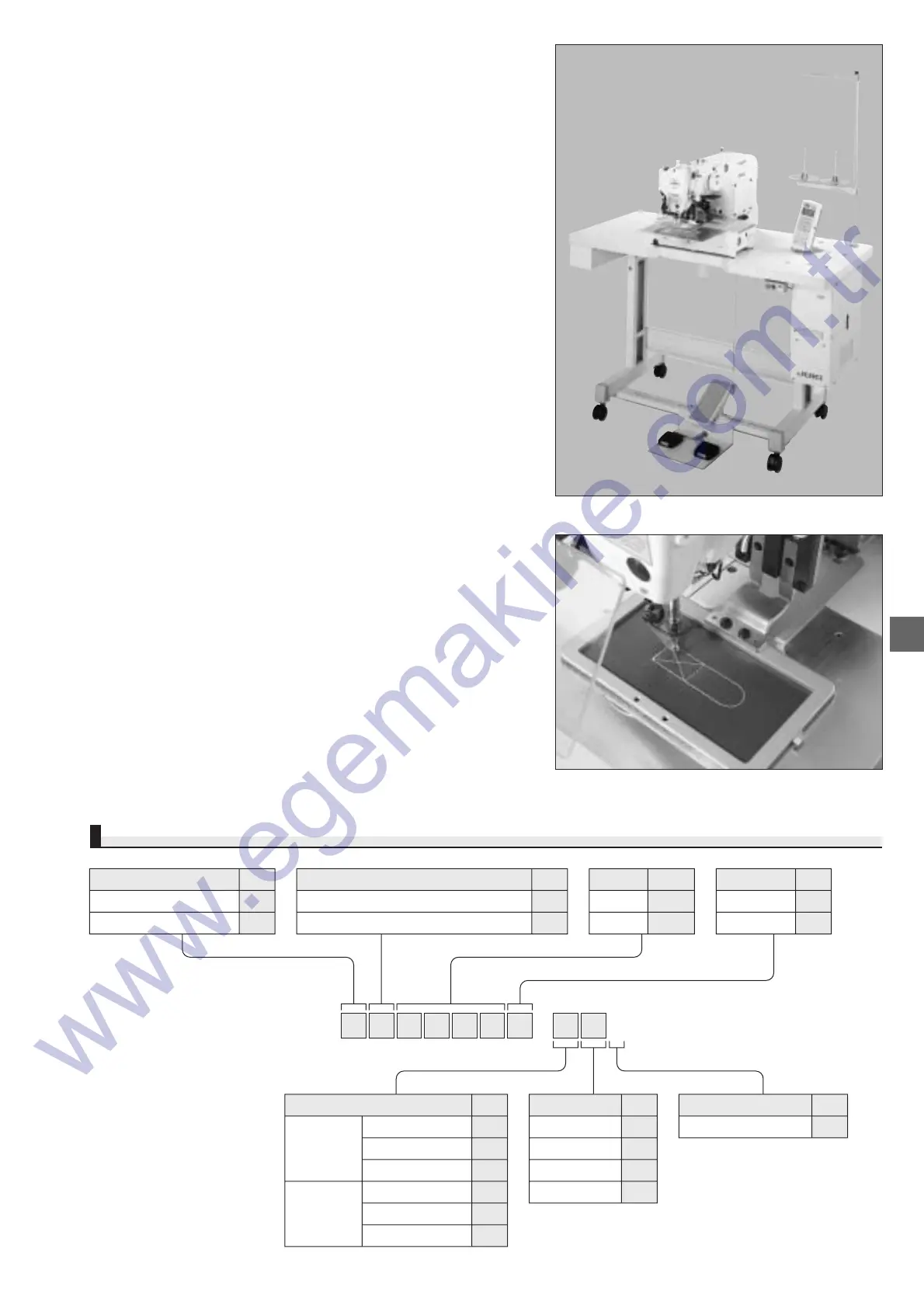

AMS210D Z B

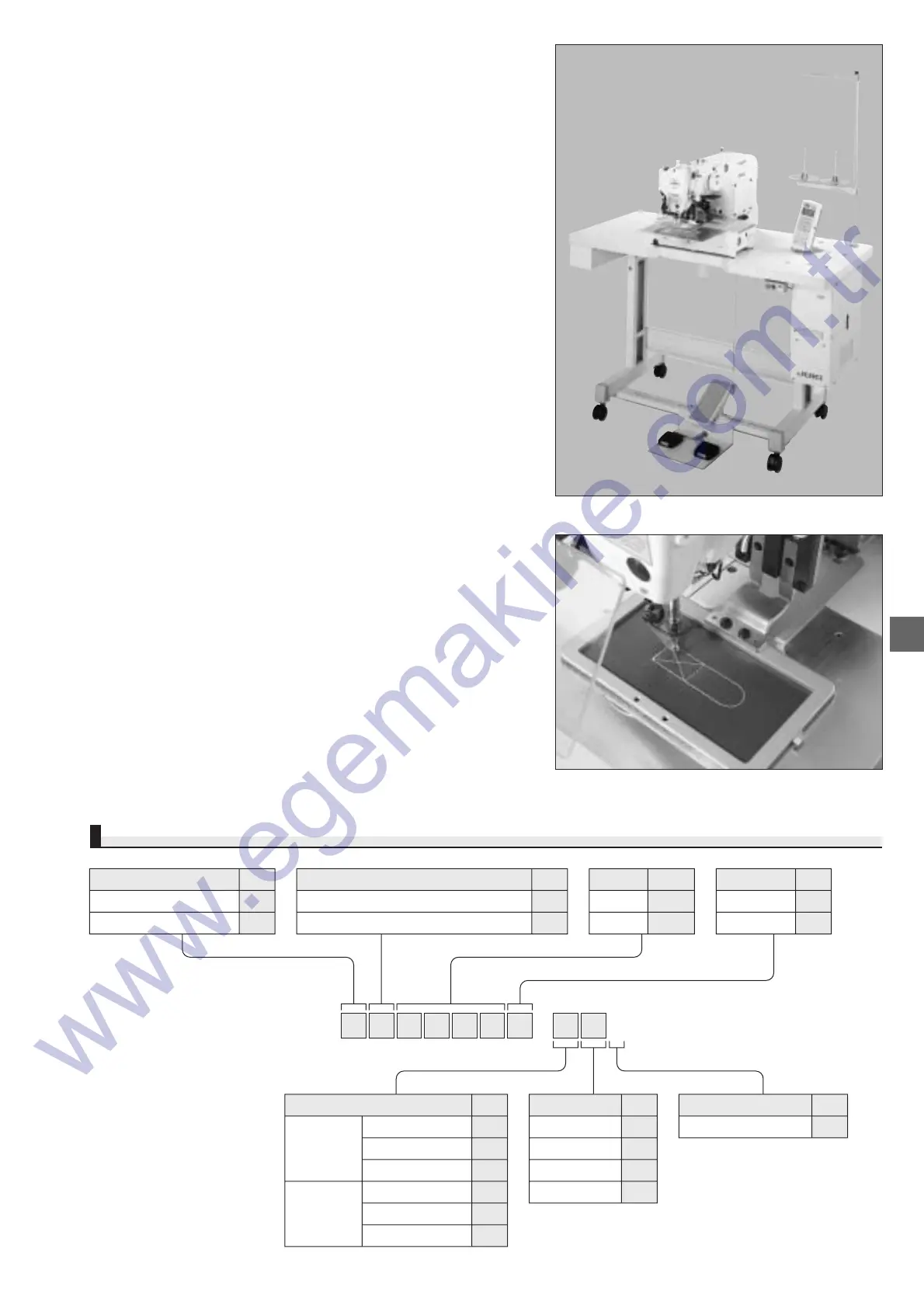

AMS-210D

AMS-210D (P type)

WHEN YOU PLACE ORDERS

● With its newly designed thread take-up and shuttle hook, the machine

reduces irregular stitches and provides consistent thread tension.

● The feeding frame and the intermediate presser have been improved to

provide a higher pressure on the material. By securely clamping the

material, they ensure consistent-quality seams free from uneven

material feed.

● The sewing capability has been improved further, especially sewing

heavy-weight materials with thick thread.

● High-speed performance of 2500rpm (when stitch length is set to 3mm).

● The lift of the feeding frame is now as high as 30mm (for pneumatic

feeding frame), and the lift of the intermediate presser has also been

extended to 20mm.

With these increased lifts, the material to be sewn can be easily placed

on the machine.

● The machine incorporates a direct-drive mechanism that connects a

compact AC servomotor directly to the main shaft. This transmits

motor revolutions to the main shaft with no loss, thereby improves the

machine's responsiveness.

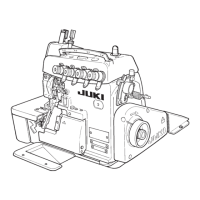

AMS-210D

〈Sewing area: 60mm(L)×130mm(W)〉

● As a result of JUKI's thorough study of sewing performance, the area in

which hitch stitches appears is reduced to one-third or less of the area

produced with conventional cycle machines. Consequently, the

sewing area finished with perfect stitches is enlarged, and the seam

quality of top stitches is further upgraded.

● Since the feeding direction of the hitch stitching area is restricted to a

range of 5˚to 55˚, each of the four different feeding directions

(0˚, 90˚, 180˚and 270˚) used to sew the four sides of a rectangular

label can be finished with perfect stitching.

AMS-210D P TYPE

〈Sewing area: 60mm(L)×130mm(W)

〉

Application Code

Standard S

For heavy-weight materials H

Subclass Code

Standard 5000

Subclass 6001〜

Stitch type Code

Standard S

Perfect stitch P

Feeding frame type Code

Magnet-driven feeding frame S

Pneumatic separately-driven feeding frame L

Control panel Code

English and pictograph B

Power supply Code

100〜120V C

Single-phase 200〜240V K

220〜415V R

200〜240V D

3-phase 220〜415V L

220〜415V (For CE) M

Pedal switch Code

2-pedal unit A

3-pedal unit B

PK 2-pedal unit C

PK 3-pedal unit D

*For using magnet-driven feeding frame type,

please select A or C type. (Standard: C type)

*For using Pneumatic separately-driven feeding

frame type, please select B or D type.

Computer-controlled Cycle Machine with Input Function

Computer-controlled Cycle Machine with Input Function

for Wider-area Perfect Stitching

Loading...

Loading...