AMS-223C, 224C, 223P, 224P (September, 2003) 1/4

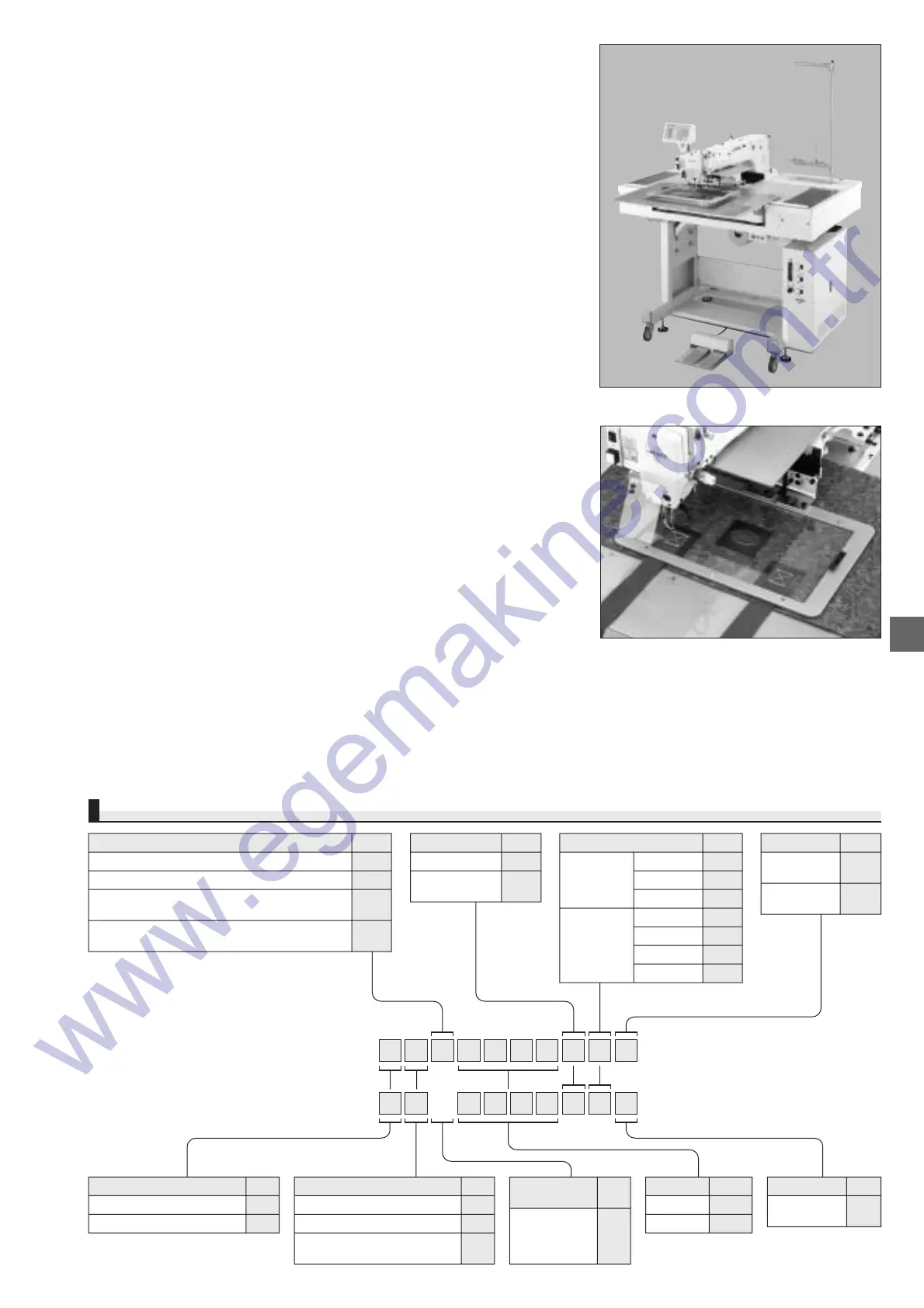

AMS223

Code

S

B

T

L

Feeding frame type

Standard (pneumatic monolithic feeding frame)

Pneumatic double-stepped stroke feeding frame

Pneumatic inverted clamp

(with a double-stepped stroke feeding frame)

Pneumatic separately-driven feeding frame

(with a double-stepped stroke feeding frame)

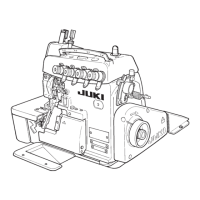

● Best-suited for sewing processes to attach small parts onto shoes or bags,

attach pockets onto garments, sew decorative stitches, etc.

● There is sufficient area under the arm (sewing area + free space 290mm

(AMS-223C) or 240mm (AMS-224C)).

● The feeding frame can go up as high as 30mm, which means that a heavy-

weight material can be handled with ease.

● The feeding frame can also be manually lowered. This allows the operator

to finely adjust the position of the material to be sewn.

● The machine is capable of sewing at a speed as high as 2,000rpm

(when the stitch length is set to 3mm (AMS-223C) or 2.7mm (AMS-224C)).

● The machine is equipped with a large hook which reduces the frequency that

the bobbin thread needs to be replaced.

● The machine ensures accurate stitching with a resolution as precise as 0.1mm.

● The newly-developed XY mechanism further improves strength and rigidity of

the feed.

● Thread trimming mechanism ensures highly-improved reliability.

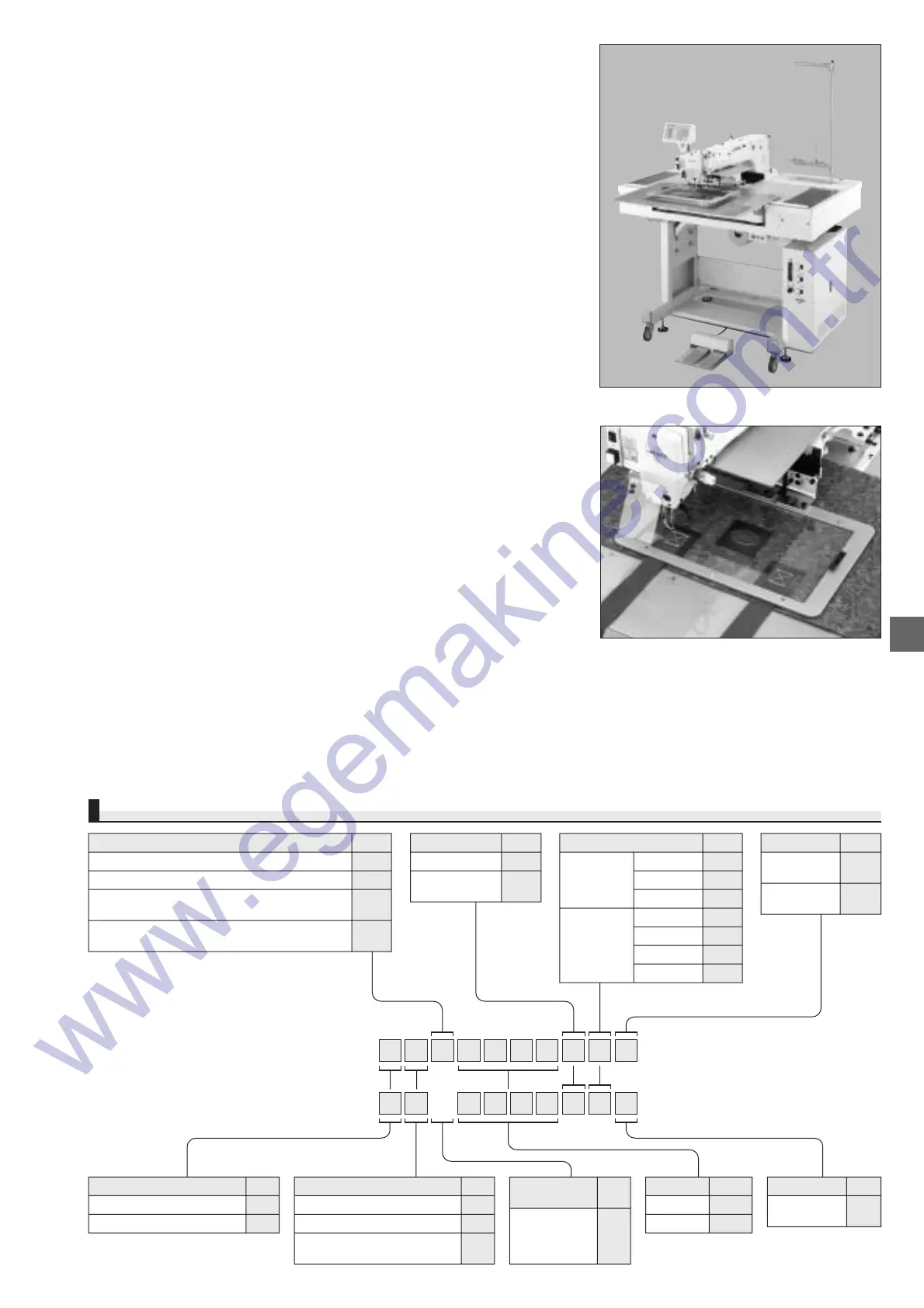

AMS-223C

〈Sewing area: 200mm(L)×300mm(W)〉

AMS-224C

〈Sewing area: 250mm(L)×400mm(W)〉

Computer-controlled Cycle Machine with Input Function

● As a result of JUKI's thorough study of sewing performance, the area in which

hitch stitches appears is reduced to one-third or less of the area produced

with conventional cycle machines. Consequently, the sewing area finished

with perfect stitches is enlarged, and the seam quality of top stitches is

further upgraded.

● Since the feeding direction of the hitch stitching area is restricted to a range

of 5˚to 55˚, each of the four different feeding directions (0˚, 90˚, 180˚and

270˚) used to sew the four sides of a rectangular label can be finished with

perfect stitching.

AMS-223P

〈Sewing area: 200mm(L)×300mm(W)〉

AMS-224P

〈Sewing area: 250mm(L)×400mm(W)〉

Computer-controlled Cycle Machine with Input Function

for Wider Area Perfect Stitching

• For the machine with sewing specification G, the feeding

frame that can be used with it is limited to S, B or L.

AMS224 B

Code

S

H

G

Application

Standard

For medium-weight materials

For heavy-weight materials with

double-capacity shuttle hook

Code

Y

B

Option

Not provided

Automatic

bobbin changer

Code

C

P

Machine head type

Standard

Wider-area perfect stitching*

Code

5000

5001〜

Subclass

Standard

Subclass

Code

C

D

Pedal switch

Standard

(2-pedal unit)

3-pedal unit

(PK47)

Code

D

Pedal switch

3-pedal unit

(PK47)

Code

B

Feeding frame

type

Pneumatic

double-stepped

stroke feeding

frame

Code

D

E

H

F

G

J

K

Power supply

100〜130V

Single-phase 190〜250V

U.S.A.,115V

190〜250V

3-phase

380〜440V

U.S.A.,220V

(JE)380V

AMS-223C

WHEN YOU PLACE ORDERS

• AC 2P motor is used for the

sewing application type G.

*For the AMS-223P and AMS-224P,

only the application S and H are

applicable.

Loading...

Loading...