MAINTENANCE

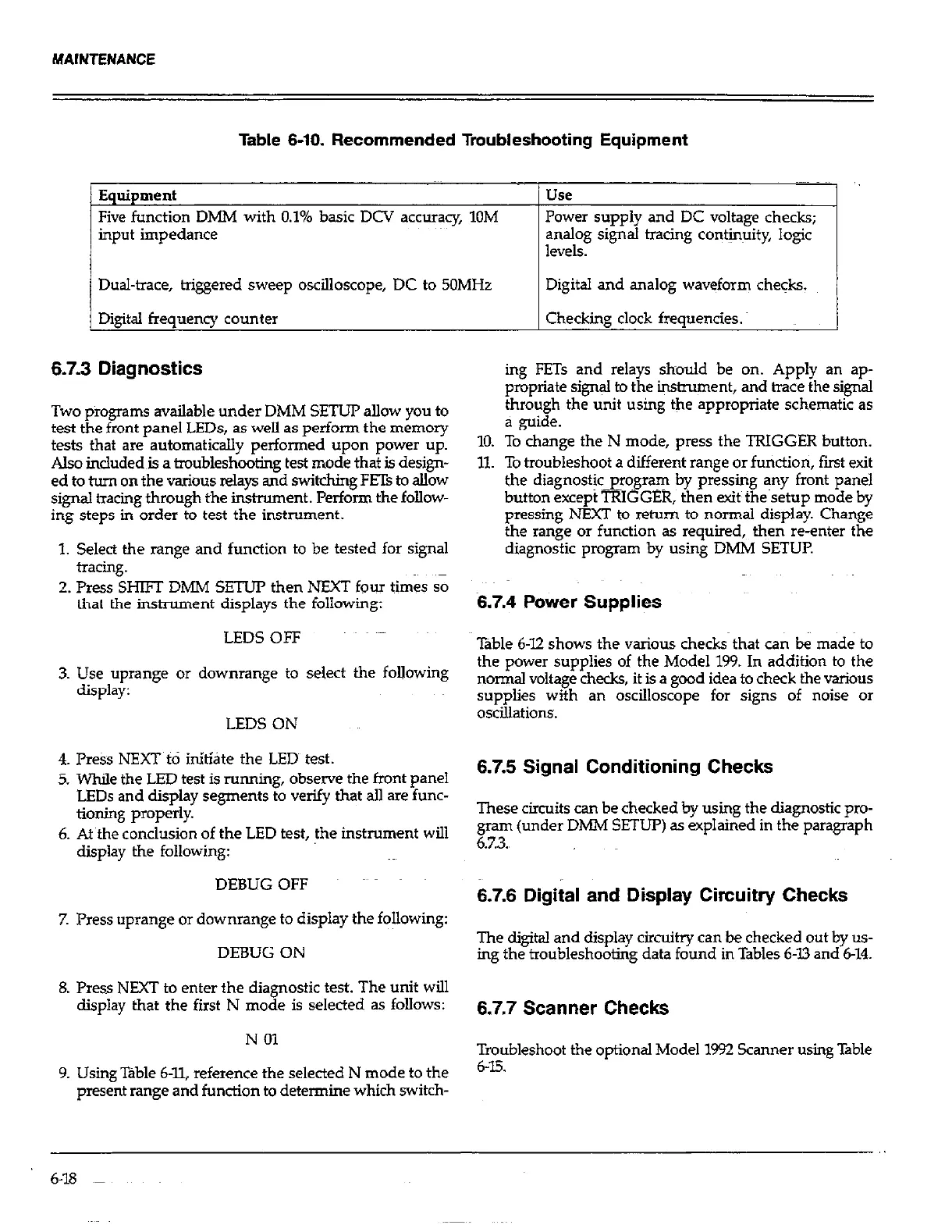

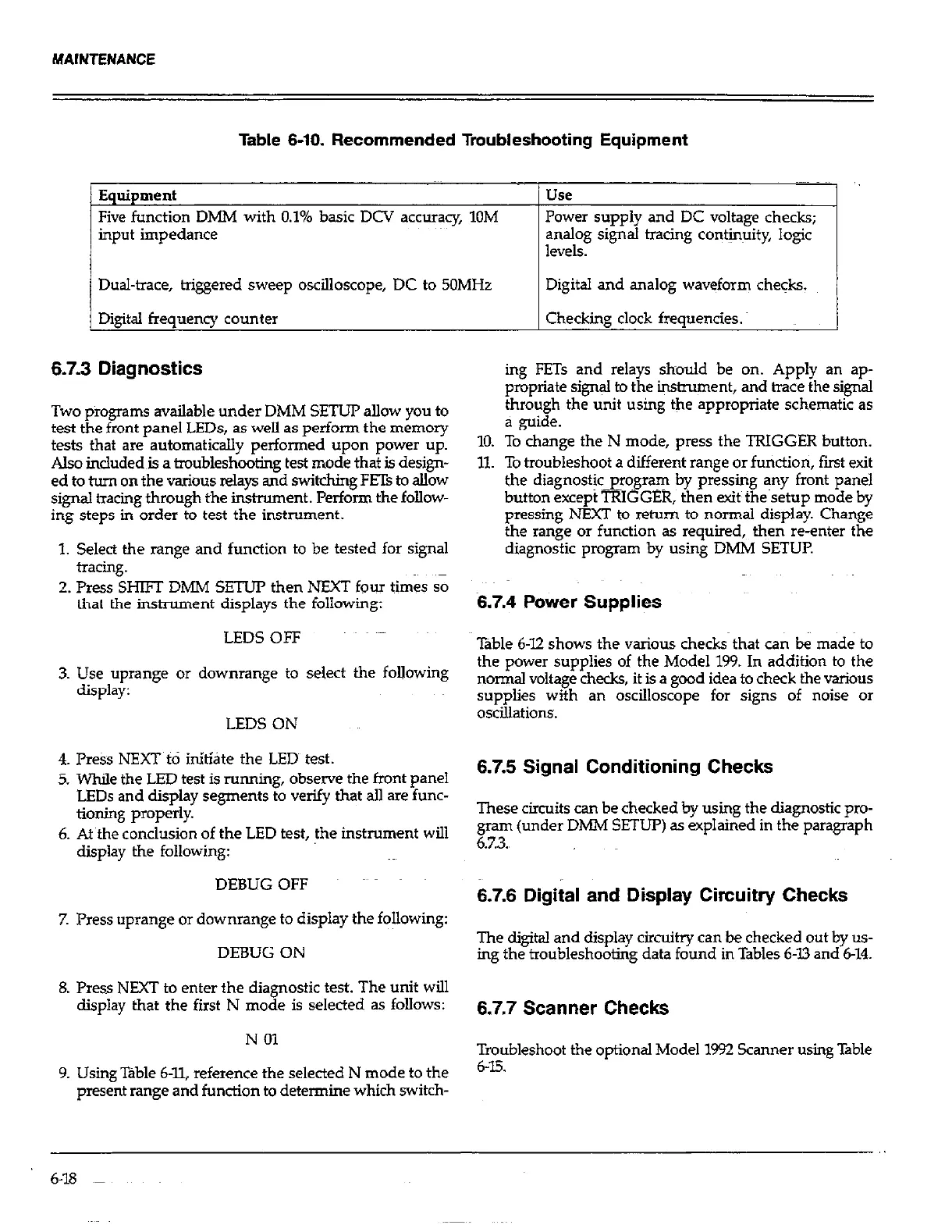

Table 6-10. Recommended Troubleshooting Equipment

Equipment

Five function DMM with 0.1% basic DCV accuracy, 10M

input impedance

Dual-trace, triggered sweep oscilloscope, DC to 50MHz

Digital frequency counter

6.7.3 Diagnostics

Two p?ograms available under DMM SETUP allow you to

test the front panel LEDs, as well as perform the memory

tests that are automatically performed upon power up.

Also included~is a truubleshooting test mode that is design-

ed to turn on the various relays and switching FETs to allow

signal tracing through the instrument. Perform the follow-

ing steps in order to test the instrument.

1. Select the range and function to be tested for signal

tracing.

2. Press SHm DMM SETUP then NEXT four times so

that the instrument displays the following:

LEDS OFF

3. Use uprange or downrange to select the following

display:

LEDS ON

4. P&s NEXT t0 initiate the LED test.

5. While the LED test is running, observe the front panel

LEDs and display segments to verify that all are func-

tioning properly.

6. At the conclusion of the LED test, the instrument will

display the following:

DEBUG OFF

7. Press uprange or downrange to display the following:

DEBUG ON

8. Press NEXT to enter the diagnostic test. The unit will

display that the first N mode is selected as follows:

N 01

9. Using Table 6-Q reference the selected N mode to the

present range and function to determine which switch-

Use

Power supply and DC voltage checks;

analog signal tracing co#jnuity, logic

levels.

Digital and analog waveform che&.

Checking clock frequencies.

ing FETs and relays should be on. Apply an ap-

propriate signal to the instrument, and trace the signal

through the unit using the appropriate schematic as

a guide.

10. To change the N mode, press the TRIGGER button.

11. To troubleshoot a different range or function, fmt exit

the diagnostjc-program by pressing any front panel

button except TRIGGER, then exit the setup mode by

pressing NEXT to return to normal display. Change

the range or function as required, then reenter the

diagnostic program by using DMM SETUP.

6.7.4 Power Supplies

Table 6-12 shows the various checks that can be made to

the power supplies of the Model 199. In addition to the

normal voltage checks, it is a good idea to check the various

supplies with an oscilloscope for signs oft noise or

oscillations.

6.7.5 Signal Conditioning Checks

These circuits can be checked by using the diagnostic pro-

gram (under DMM SETUP) as explained in the paragraph

6.7.3.,

6.7.6 Digital and Display Circuitry Checks

The digital and display circuitry can be checked out by us-

ing the troubleshooting data found in Tables 6X3 and 6-14.

6.7.7 Scanner Checks

Troubleshoot the optional Model 1992 Scanner using Table

6-E

Loading...

Loading...