114

TROUBLESHOOTING

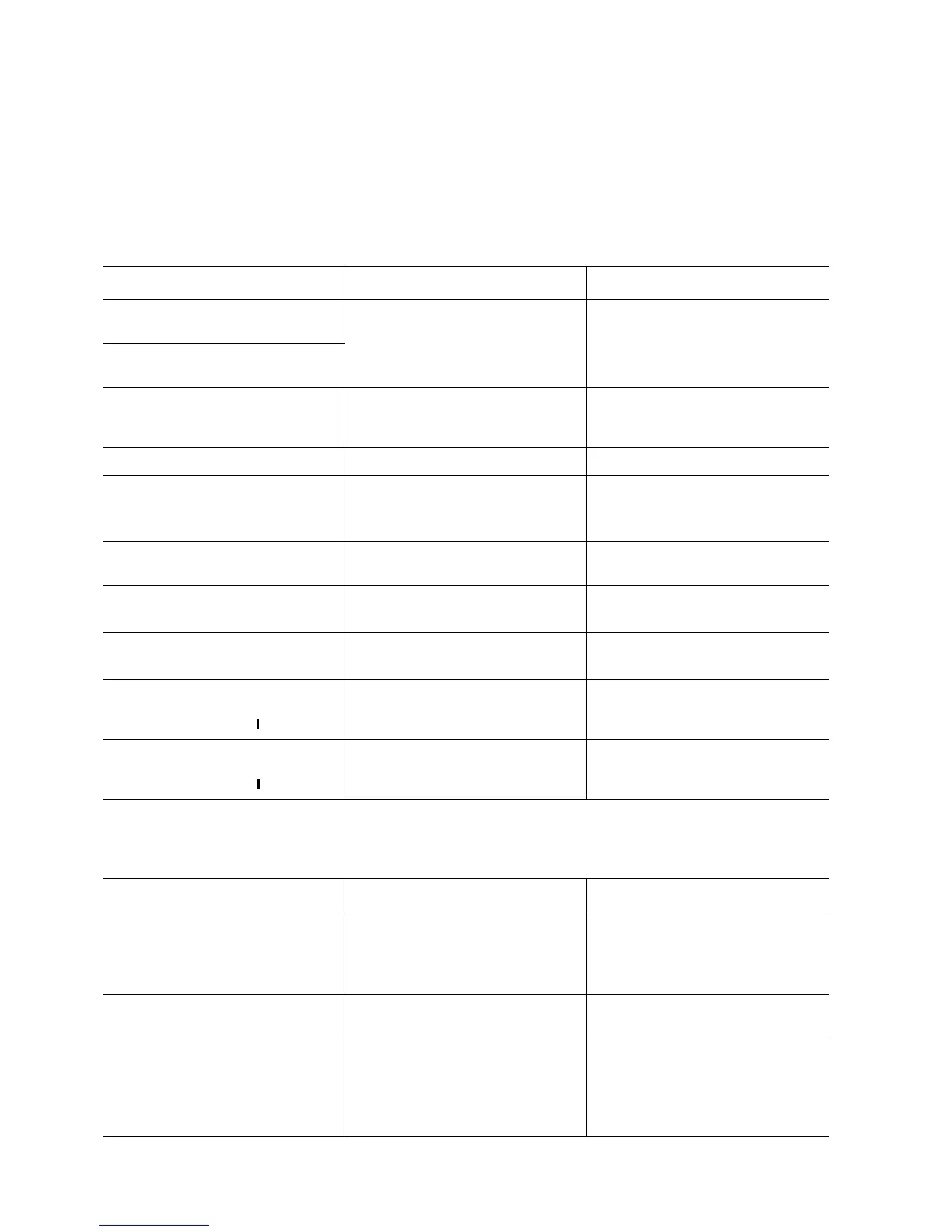

3.15.5 OTHER TROUBLES

3.15.5.1 ELECTRICAL CIRCUIT

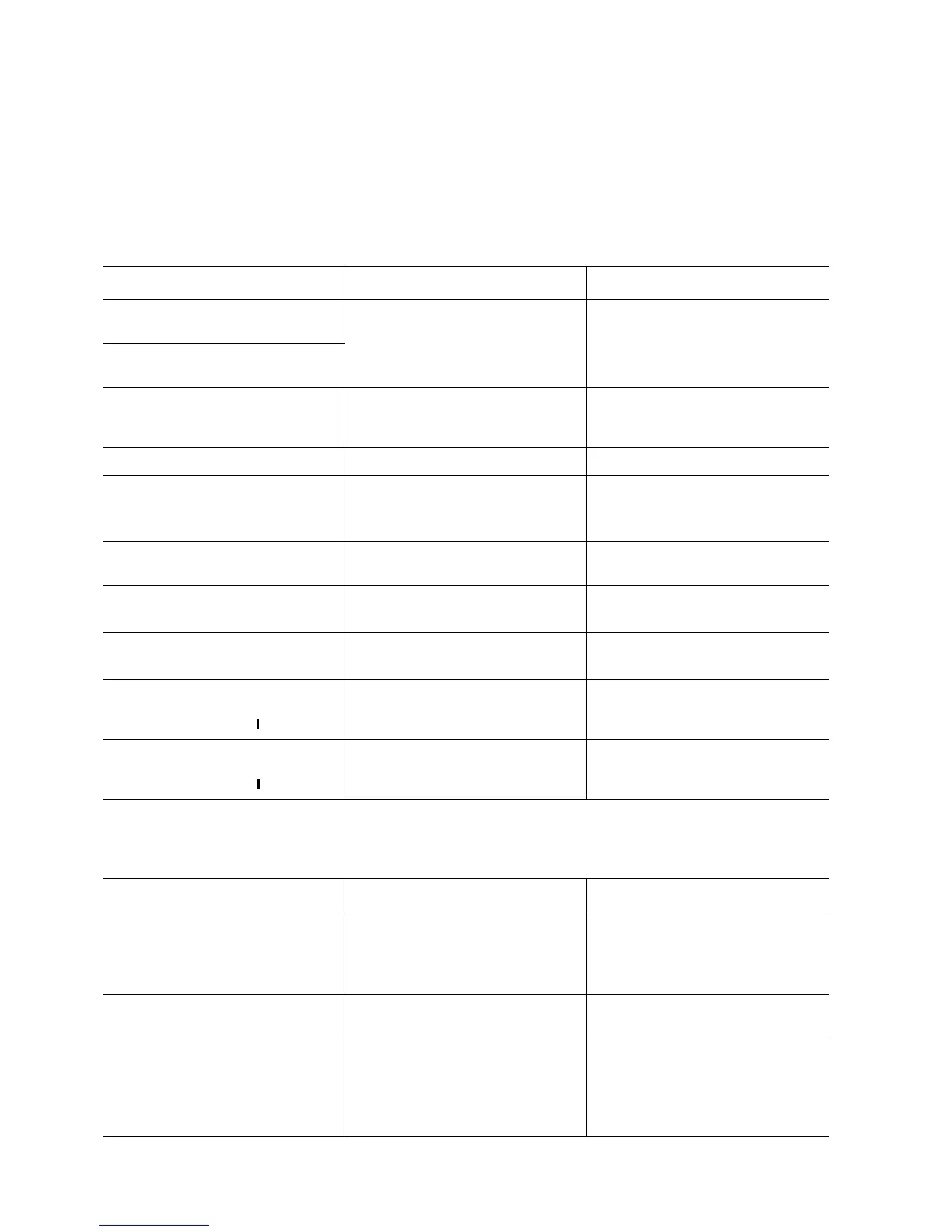

3.15.5.2 HYDRAULIC SYSTEM

(•): Always contact your Komatsu Utility Dealer when you have to carry out this operation.

• : If the anomaly or its cause are not included in the failures indicated below, contact your Komatsu Utility Deal-

er for the necessary repair.

TROUBLE CAUSE REMEDY

Lights do not work satisfactorily even

with engine running at high speed:

• Faulty cables.

• Faulty fan belt tension.

(•) Check and repair any loose termi-

nal and connection.

• Adjust fan tension (see “EVERY 250

HOURS”).

Lights come on intermittently with

engine running:

Alternator charge warning light does

not go out with engine running and

increasing speed:

• Faulty alternator.

• Faulty cables.

(•) Change.

(•) Check and repair.

Alternator emits an abnormal noise:

• Faulty alternator. (•) Change.

Starter does not turn with key in

START position:

• Faulty cables.

• Battery charge insufficient.

• Faulty main fuse.

(•) Check and repair.

• Charge battery.

• Change.

Starter pinion engages and then dis-

engages:

• Battery charge insufficient. • Charge battery.

Starter makes engine run slowly:

• Battery charge insufficient.

• Faulty starter.

• Charge battery.

(•) Change.

Starter disengages before engine has

started:

• Faulty cables.

• Battery charge insufficient.

(•) Check and repair.

• Charge battery.

Engine oil pressure warning light does

not come on when engine is stopped

(ignition key in position «»):

• Faulty bulb.

• Faulty pressure sensor.

(•) Change.

(•) Change.

Alternator charge warning light does

not come on when engine is stopped

(ignition key in position «»):

• Faulty bulb.

• Faulty cables.

(•) Change.

(•) Check and repair.

TROUBLE CAUSE REMEDY

Pump emits an abnormal noise:

• No oil in the tank.

• Faulty pump.

• Hydraulic oil unsuitable for the tem-

perature.

• Top up.

(•) Repair or change.

• Change.

Equipment control levers do not return

automatically to neutral position:

• Broken return spring or seized ele-

ment.

(•) Change spring or distributor ele-

ment.

Equipment moves only at low speed:

• Faulty pump.

• Max. pressure valve setting incor-

rect, or valves not closed due to im-

purities.

• Dirty drain filter.

(•) Repair or change.

(•) Set or change.

• Change.

Loading...

Loading...