MAINTENANCE PLAN

153

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING

• Clean the grease nozzles before applying the greasing pump.

• After lubrication, remove any excess grease.

• If the machine is used in difficult conditions, perform this maintenance operation more frequently.

These maintenace operations must be carried out with the equipment completely extended and resting on the

ground. For the lubrication, use a syringe and the prescribed grease.

(See “4.3 FUEL, COOLANT AND LUBRICANTS”).

• As a general rule, it is important to consider that each cylinder is provided with two greasers posi-

tioned on the coupling eyelets and that each pin serving as fulcrum for a movement is provided with at

least one greaser.

• When injecting grease to lubricate the rotation pinion and the ball-bearing ring, rotate the upper struc-

ture slowly and grease every 90°.

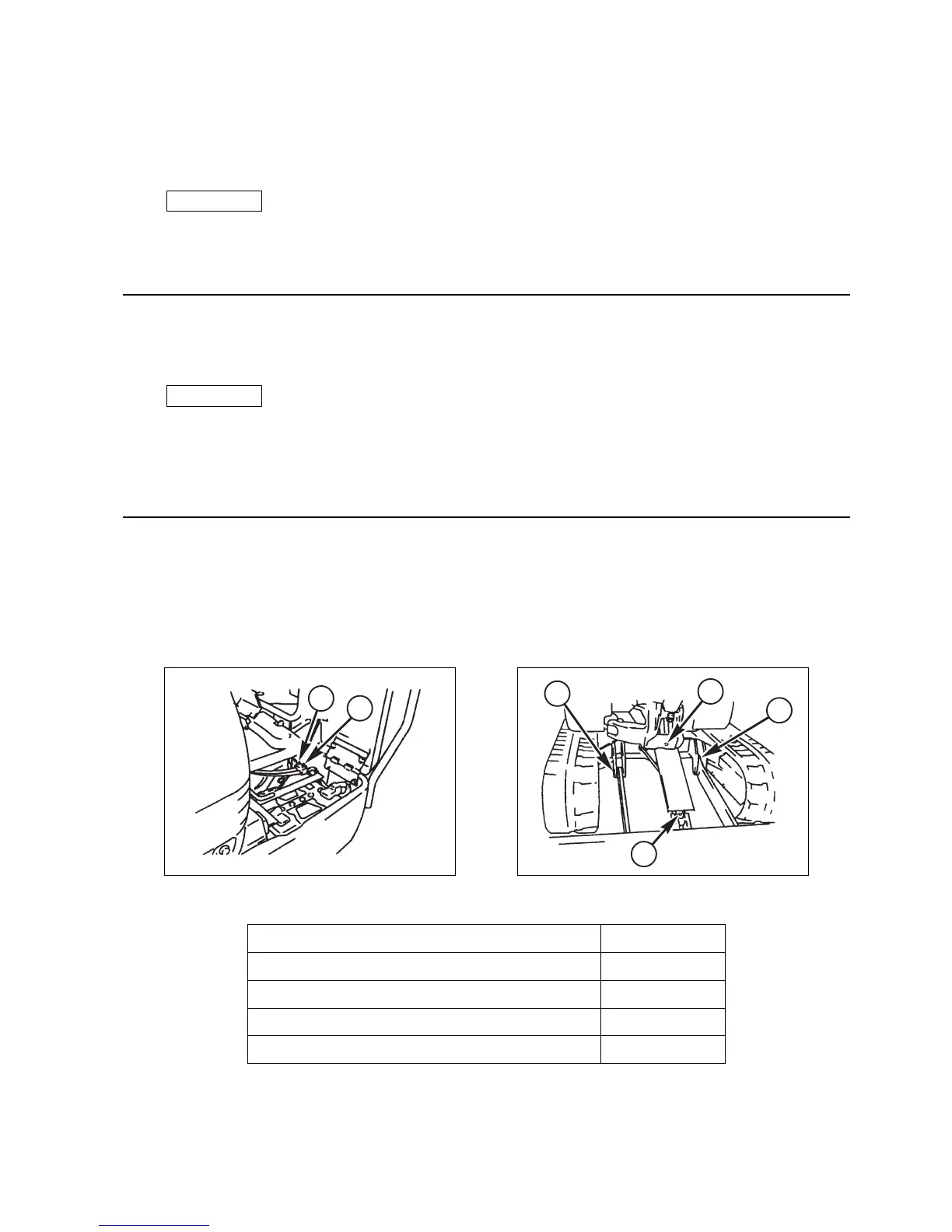

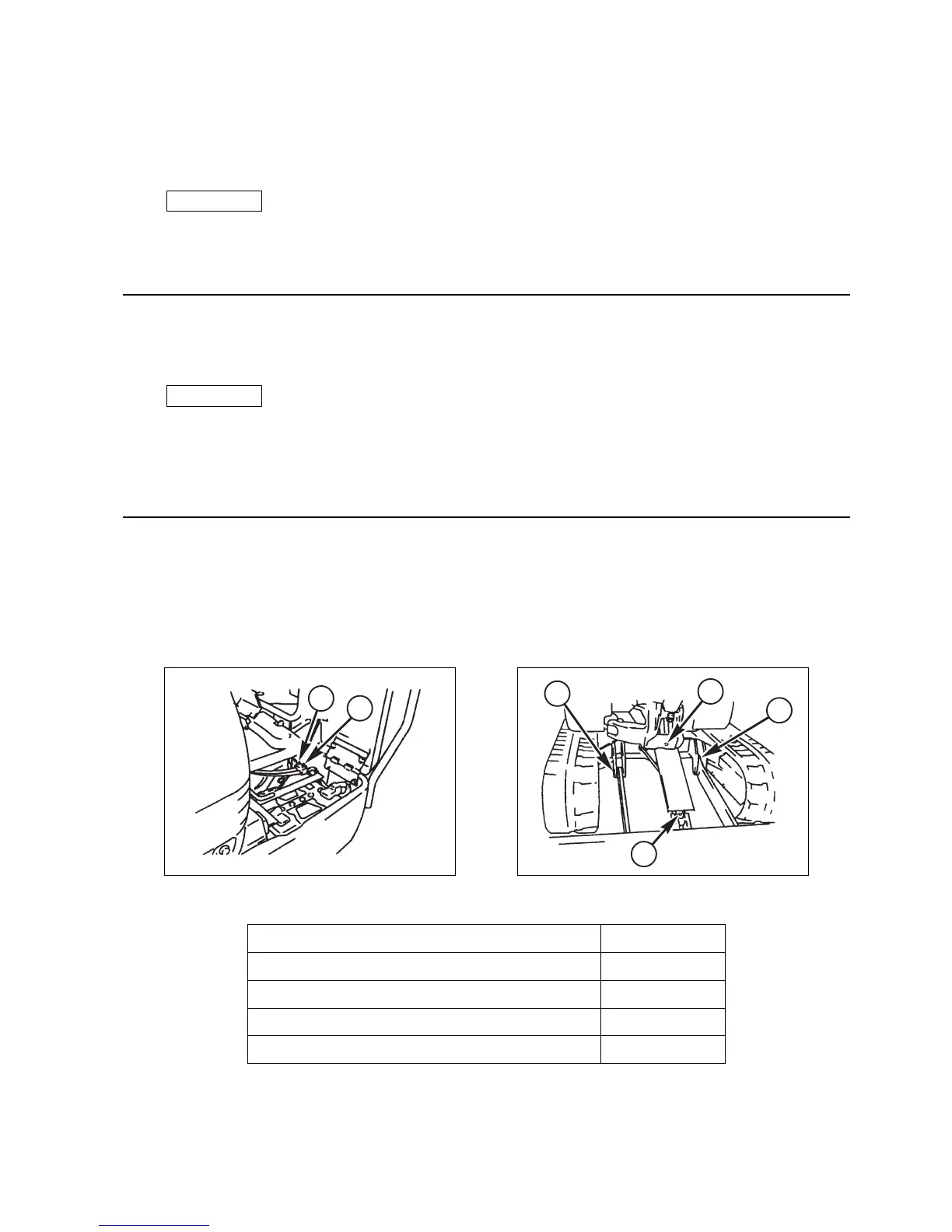

BALL-BEARING RING AND BLADE LUBRICATION POINTS

1 - Ball-bearing ring (1 point)

2 - Ball-bearing ring pinion (1 point)

3 - Blade cylinder base pin (1 point)

4 - Blade cylinder head pin (1 point)

5 - Blade fulcrum pin (2 points)

RWA09910

1

2

RWA09920

3

5

4

5

Loading...

Loading...