• Retract the bucket and arm cylinder completely, lower the

bucket teeth to the ground and, after stopping the engine,

release the residual pressures from the work equipment

circuits (by operating the controls more than once) and

from the tank (by slowly loosening the filling cap).

• Let the oil cool down until it reaches 4045°C before carry-

ing out any maintenance operation.

• Immediately clean any area dirty with oil.

1 - Rotate the upper structure of 45°, in such a way as to leave

the lower part of the hydraulic oil tank free from the tracks.

2 - Retract the bucket and arm cylinder completely and lower the

boom until the bucket teeth touch the ground.

3 - Lower the blade to the ground.

4 - Stop the engine and eliminate the residual pressures present

in the equipment (by moving the controls several times).

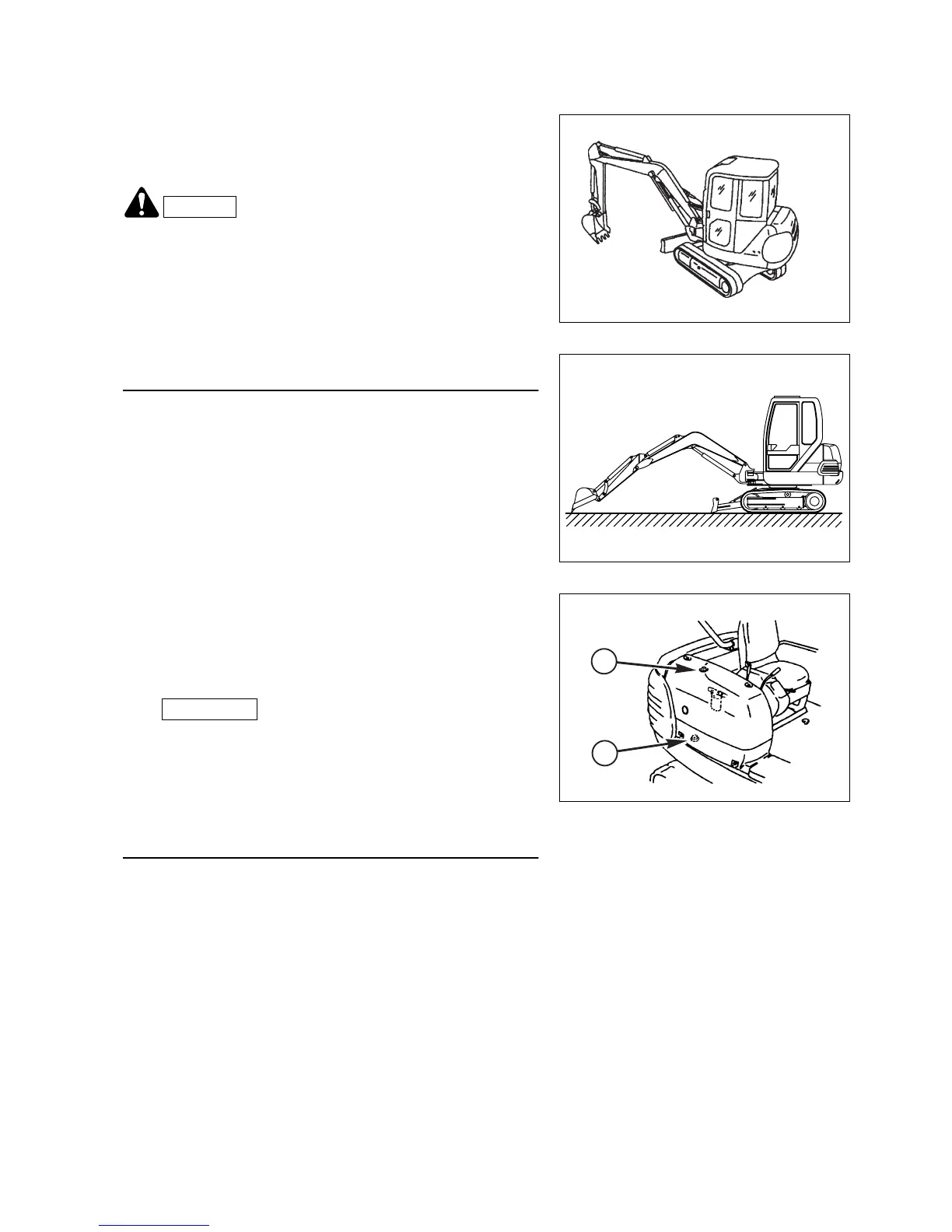

5 - Slowly loosen the filling cap (1) in order to release the residu-

al pressure that may be present in the tank.

Use a 24 mm hexagon spanner.

6 - Remove the drain plug (2) until the condensate has flown out

of the tank completely.

Use a 32 mm spanner.

7 - Put back the filling cap (1).

IMPORTANT

☞

• The draining of the tank must be carried out at tempera-

tures exceeding 0°C, before starting the engine; when the

temperature is below 0°C, the hydraulic oil tank must be

drained at the end of work, or in any case when the tem-

perature of the machine is sufficiently high to prevent the

condensate from freezing and allow it to flow out of the

tank without problems.

RWA09270

RYA12250

1

2

RWA07490

Loading...

Loading...