MAINTENANCE PLAN

150

4.7.3.e CHECKING THE OIL LEVEL IN THE HY-

DRAULIC CIRCUIT

DANGER

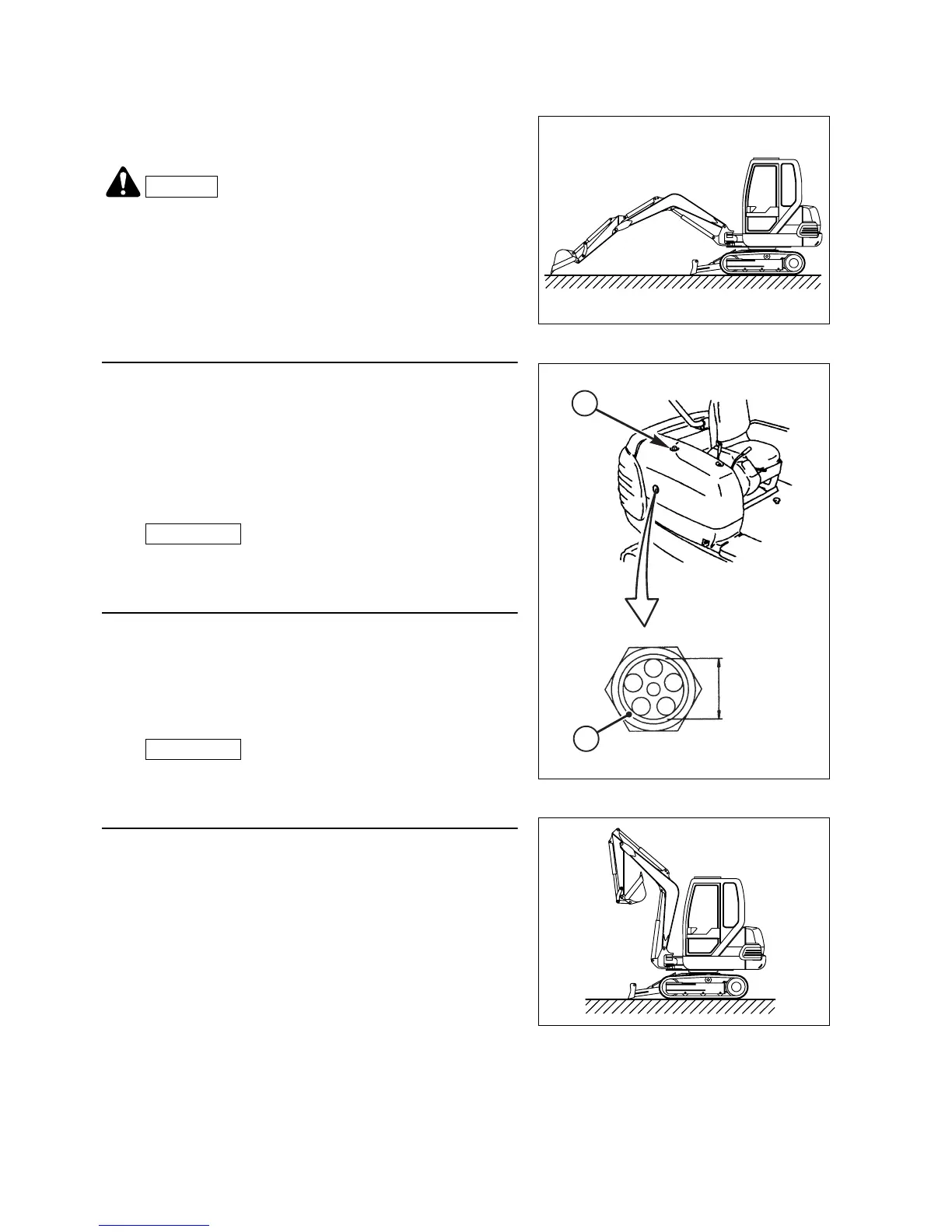

• The oil level in the hydraulic circuit must be checked with

cold oil and the machine positioned on level ground, with

retracted bucket and arm cylinders and the bucket teeth

resting on the ground.

• If it is necessary to top up, stop the engine and then elimi-

nate the residual pressures present in the equipment

(move the controls more than once) and in the tank by

slowly loosening the filling cap.

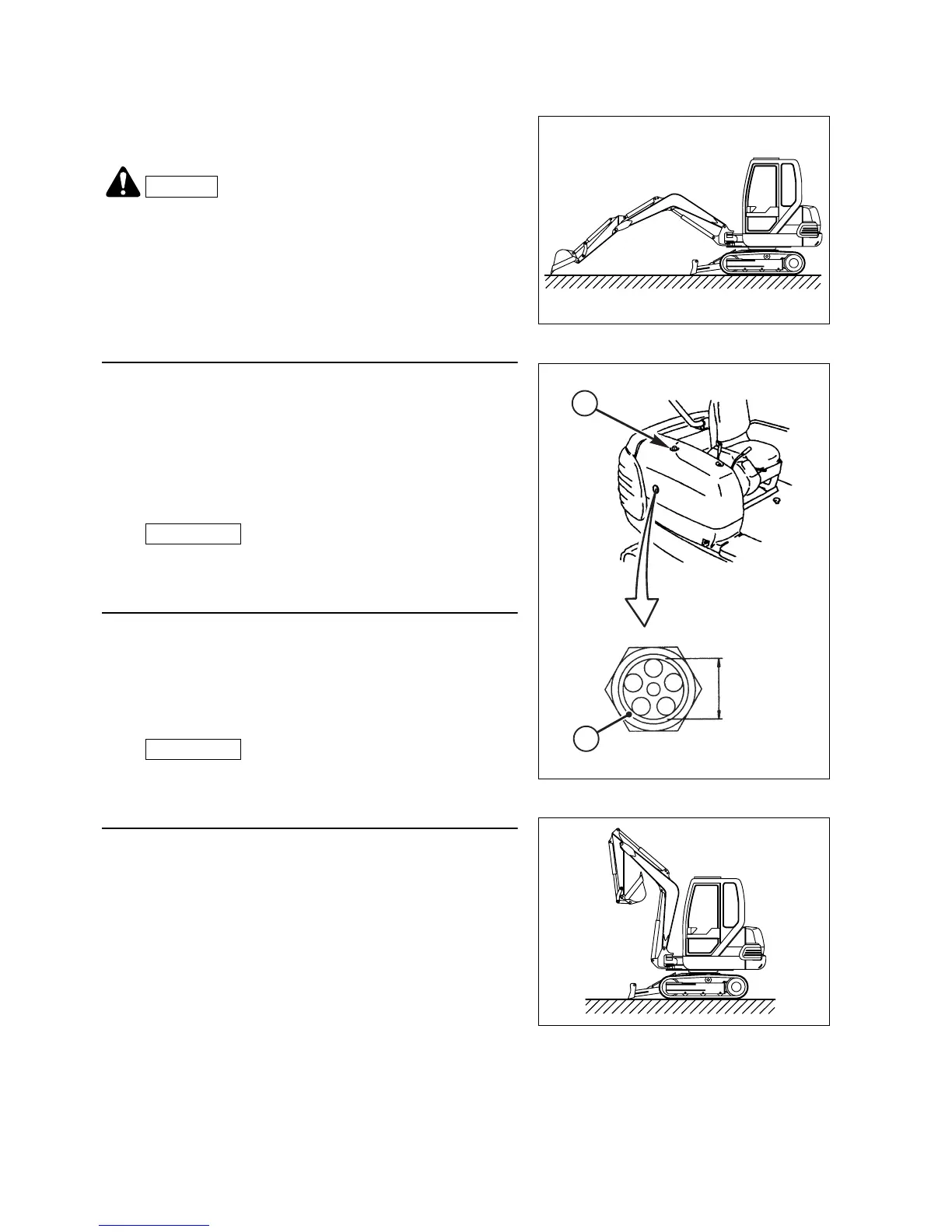

The oil level must be visible through the gauge (1) positioned on

the tank and must be included between the MIN. and MAX.

marks.

If the level is near the MIN. mark, top up by adding the pre-

scribed hydraulic oil (see “4.3 FUEL, COOLANT AND LUBRI-

CANTS”) through the filler (2); then put back the fillercap.

Use a 24 mm hexagon spanner.

• When topping up, do not exceed the MAX. level. This

would damage the hydraulic circuit and cause the oil to

flow out.

At this point, pressurize the tank; completely extend the boom,

arm and bucket cylinders as shown in the figure and remove the

fillercap (2).

Put back the cap and pressurize the inside of the tank by lower-

ing the equipment to the ground.

• If a constant or abnormal decrease in the oil level is ob-

served, carefully check the tightness of the hydraulic cir-

cuit, of the pistons and of the pump.

RWA07490

RYA12290

2

1

MAX.

MIN.

RWA06730

Loading...

Loading...