• The machine must be parked on a level surface, with the

equipment resting on the ground.

• For the installation, the hammer must be positioned hori-

zontally, with the bit directed towards the machine.

• When the coupling pins are removed or installed, chips

may come off; always wear gloves, safety goggles and

helmet.

• The change of the equipment must be carried out by two

operators, who must decide together the words and sig-

nals to be used during operations.

• Do not use your fingers to center the holes, since they

may be injured or even cut.

• Release the residual pressure that may be present in the

pipes completely.

For the installation of the demolition hammer it is necessary to

connect the mechanical constraints of the bucket as described

in “3.13.4 CHANGING THE BUCKET” and to carry out the hy-

draulic connections using the pipes provided. After connecting

the mechanical constraints, carry out the hydraulic connections

by proceeding as follows:

1 - Stop the engine and move the hydraulic controls in all direc-

tions, in order to completely release the residual pressures

present in the circuits of the machine.

2 - Press the hammer control pedal to release the residual pres-

sure present in the hammer delivery pipe.

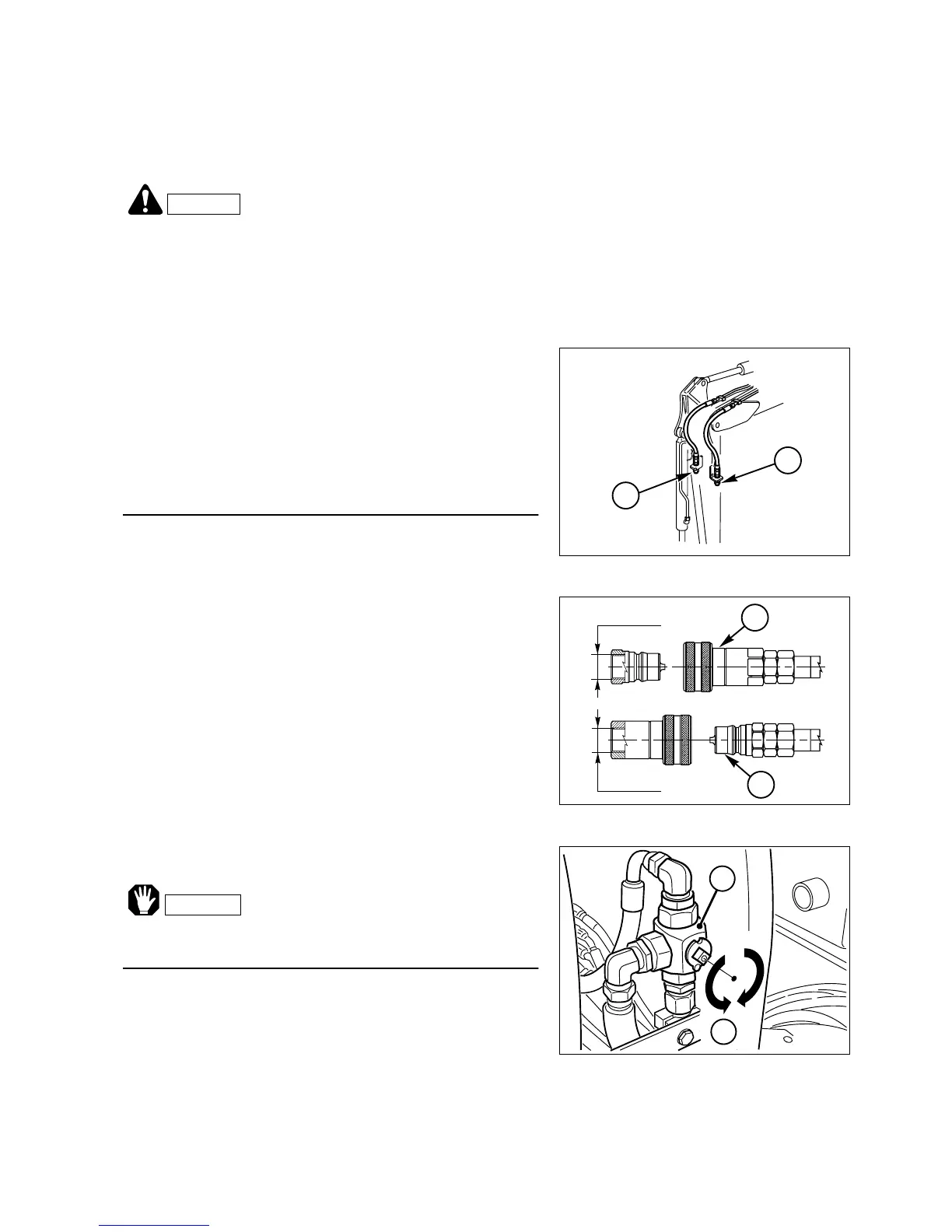

3 - Slowly loosen the hydraulic oil filling cap, in such a way as to

release the residual pressure from the tank.

4 - Remove the sealing plugs of the rapid couplings of both the

machine and the hammer.

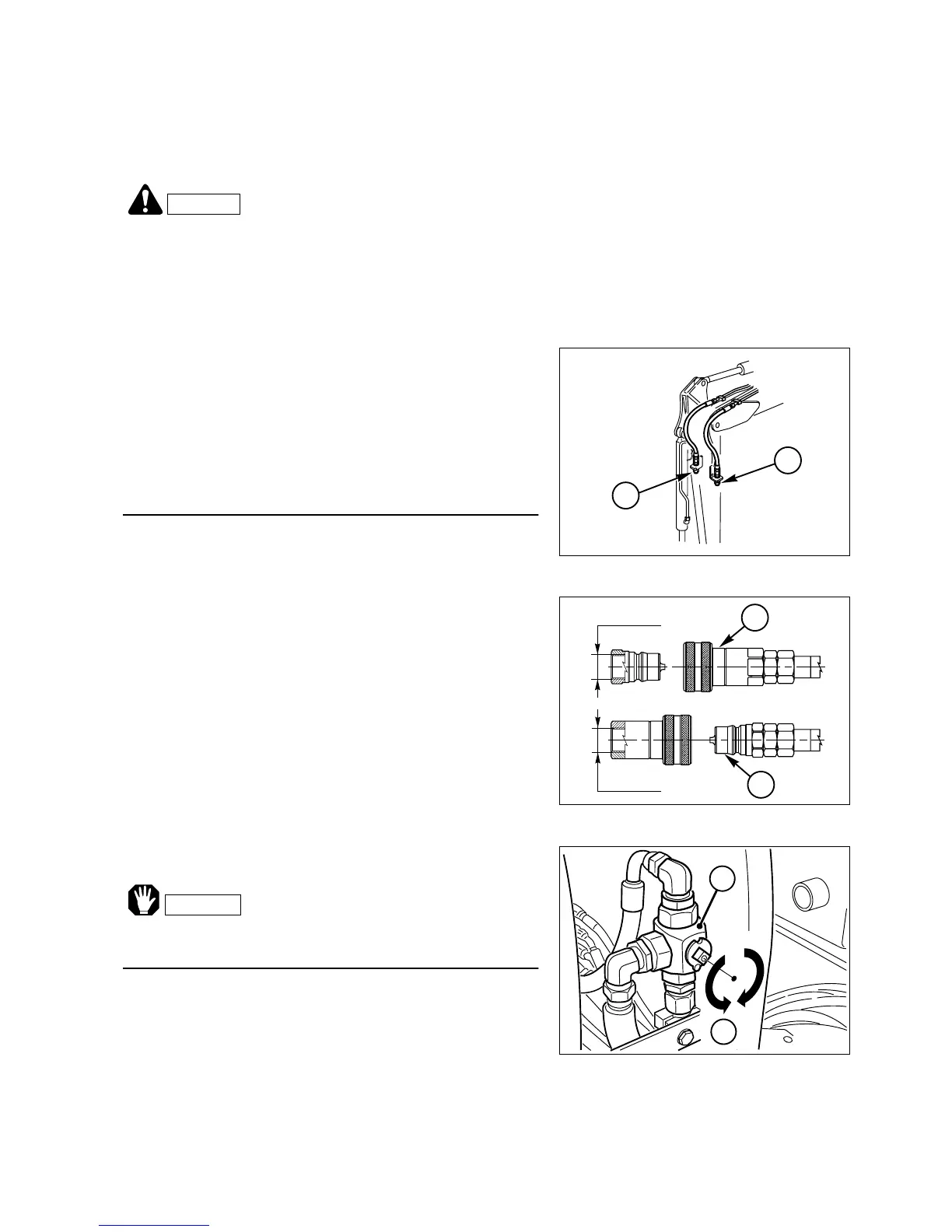

5 - Connect the right (1) and left (2) pipes. The rapid couplings

must be in compliance with the ISO 7241-1 series “B” stand-

ard.

Loading...

Loading...