3-49

PC210/240-ENG

4. If the oil does not reach the L mark F on dipstick G, add engine oil

through dipstick insertion hole F.

When refilling, remove bleeding plug a.

For details of the oil to use, see 20. “USE OF FUEL, COOLANT AND

LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE”.

5. If the oil level exceeds the H mark on the dipstick, loosen drain plug

P to drain the excess oil.

6. After checking oil level or adding oil, insert the dipstick into the hole

and install air bleeding plug a.

24.4.3 DRAIN WATER AND SEDIMENT FROM FUEL

TANK

1. Carry out this procedure before operating the machine.

2. Prepare a container to catch the fuel that is drained.

3. Open valve a at the bottom of the tank and drain the sediment and

water that has accumulated at the bottom together with fuel.

When doing this, be careful not to get fuel on yourself.

4. When only clean fuel comes out, close drain valve a.

NOTICE

Never use trichlene for washing the inside of the tank.

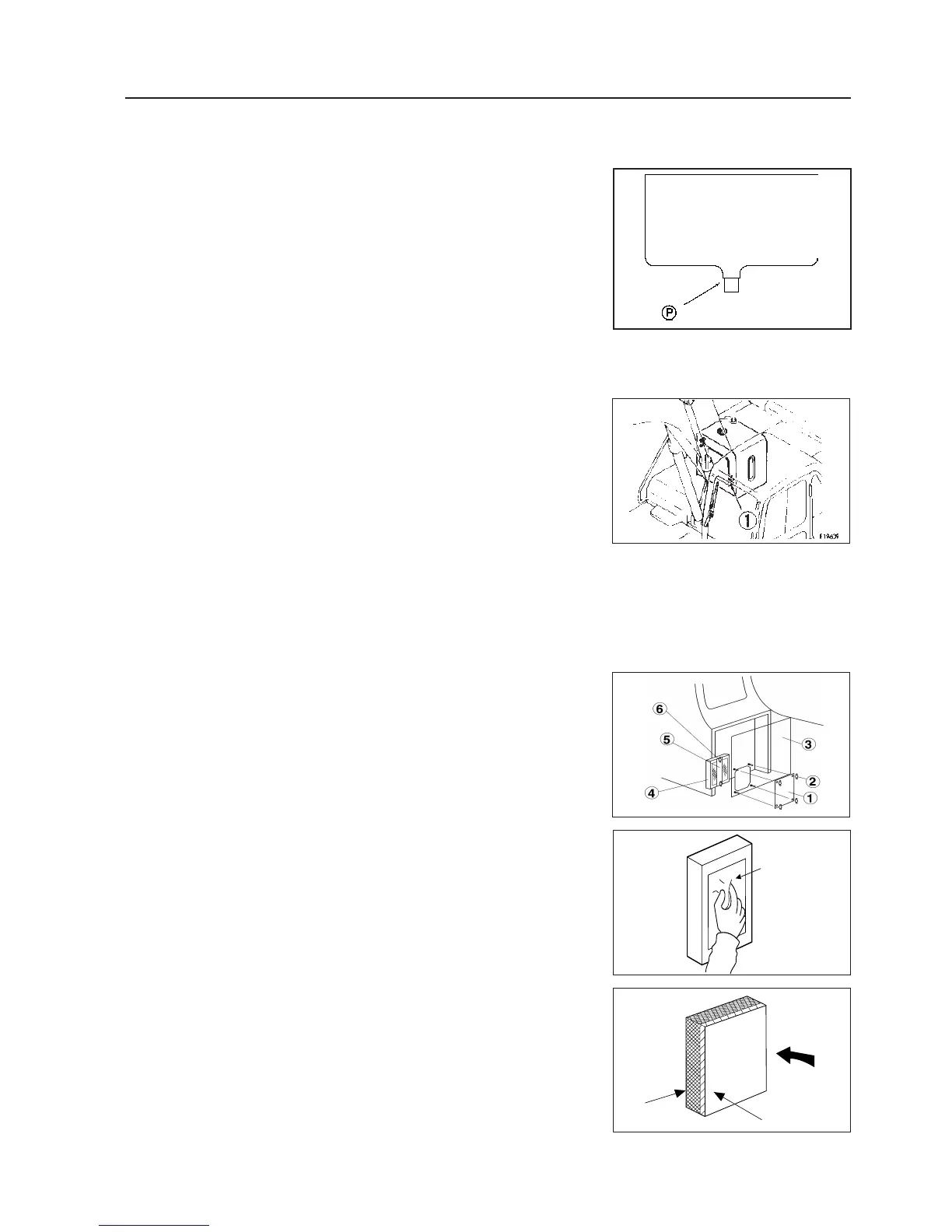

24.4.4 CLEAN FRESH AIR INTAKE FILTER

1. Remove 4 wing nuts b from partition c and remove cover a.

2. Access to filter assíy d is now possible through hole.

Remove two wings nuts f holding retaining strap e.

3. Grasp filter element g centrally and pull out of housing.

4. Note that filter element is a sandwich of a fine filter and a coarse

filter.

Clean filter by placing element in a mixture of hand hot water and

neutral detergent with the coarse filter side downwards.

Move element up and down to release dirt.

A Coarse (outside)

B Fine (inside)

g

B

A

24. SERVICE PROCEDURE

Loading...

Loading...