PERIODIC SERVICE154

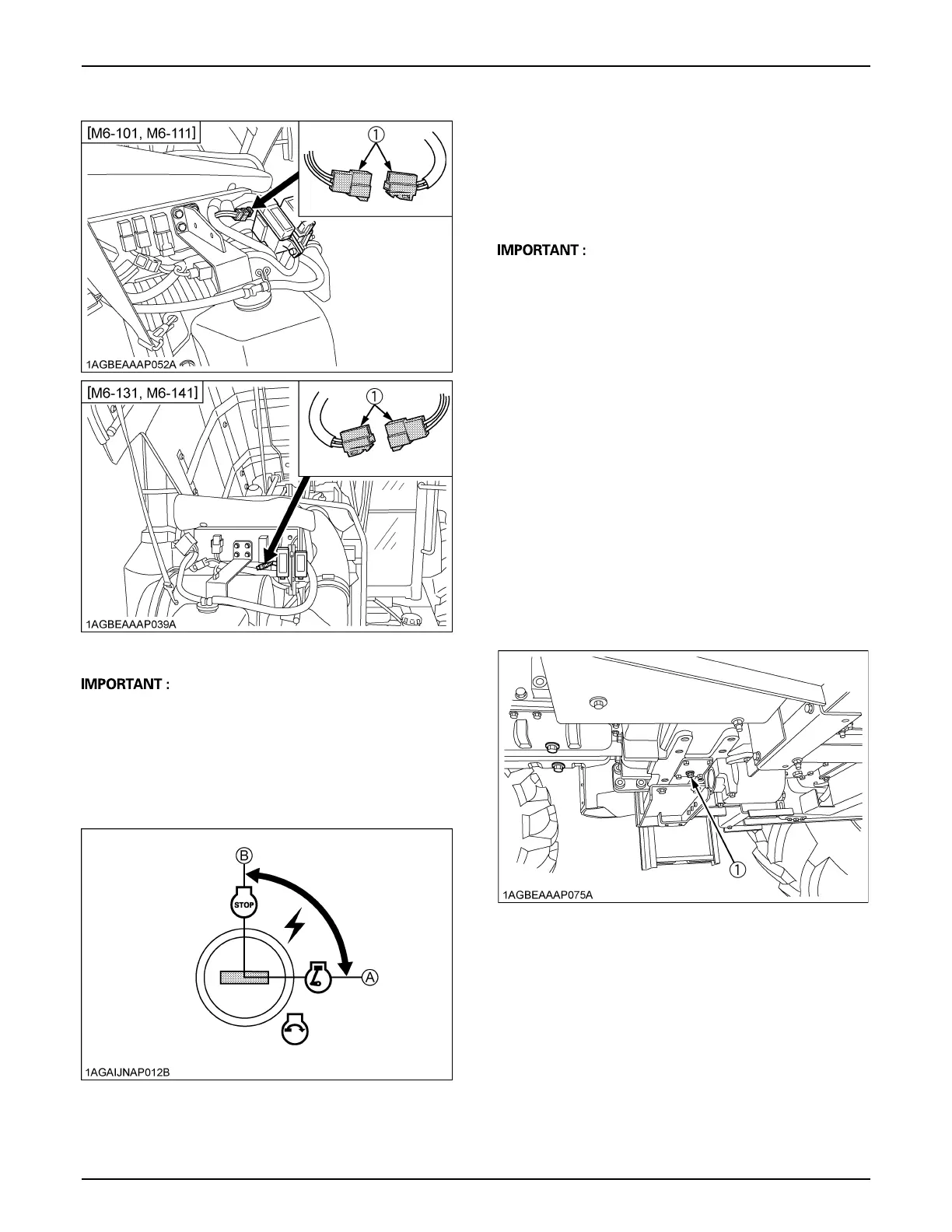

2. Disconnect the heater connector.

A Do not try air-bleeding with the heater in operation.

Otherwise the battery may get damaged.

3. Turn ON and OFF the key switch repeatedly 10 times

or so at the following intervals. This lets the air out of

the fuel line.

(1) Key switch ON time: 30 seconds

(2) Key switch OFF time: 15 seconds

4. Connect the heater connector.

5. Set both the hand and the foot throttles to the minimum

speed position, turn the key switch to start the engine

and then reset the throttle at the mid speed (around

1500 rpm) position.

If engine doesn't start, try it several times at 30 second

intervals.

A Do not hold key switch at engine start position for more

than 10 seconds continuously. If more engine cranking

is needed, try again after 30 seconds.

6. Accelerate the engine to remove the small portion of

air left in the fuel system.

7. If air still remains and the engine stops, repeat the

above steps.

BBleeding Brake System

Consult your local KUBOTA Dealer for this service.

BDraining Clutch Housing Water

The tractor is equipped with a drain plug under the clutch

housing.

After operating in rain, snow or if the tractor has been

washed, water may get into the clutch housing.

Remove the drain plug and drain the water, then install the

plug again.

(1) Connector

(1) Key switch (A) "ON"

(B) "OFF"

(1) Water drain plug