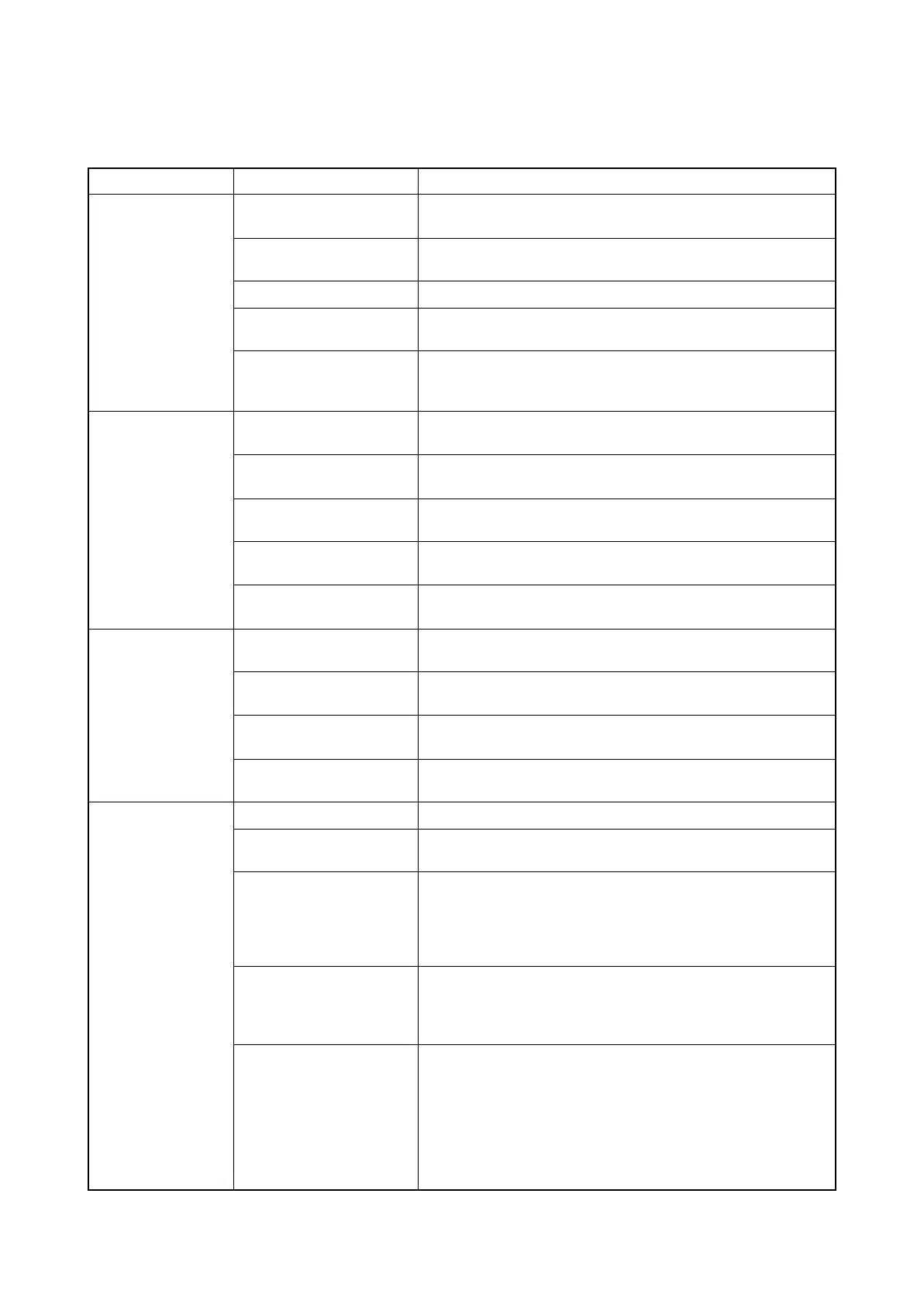

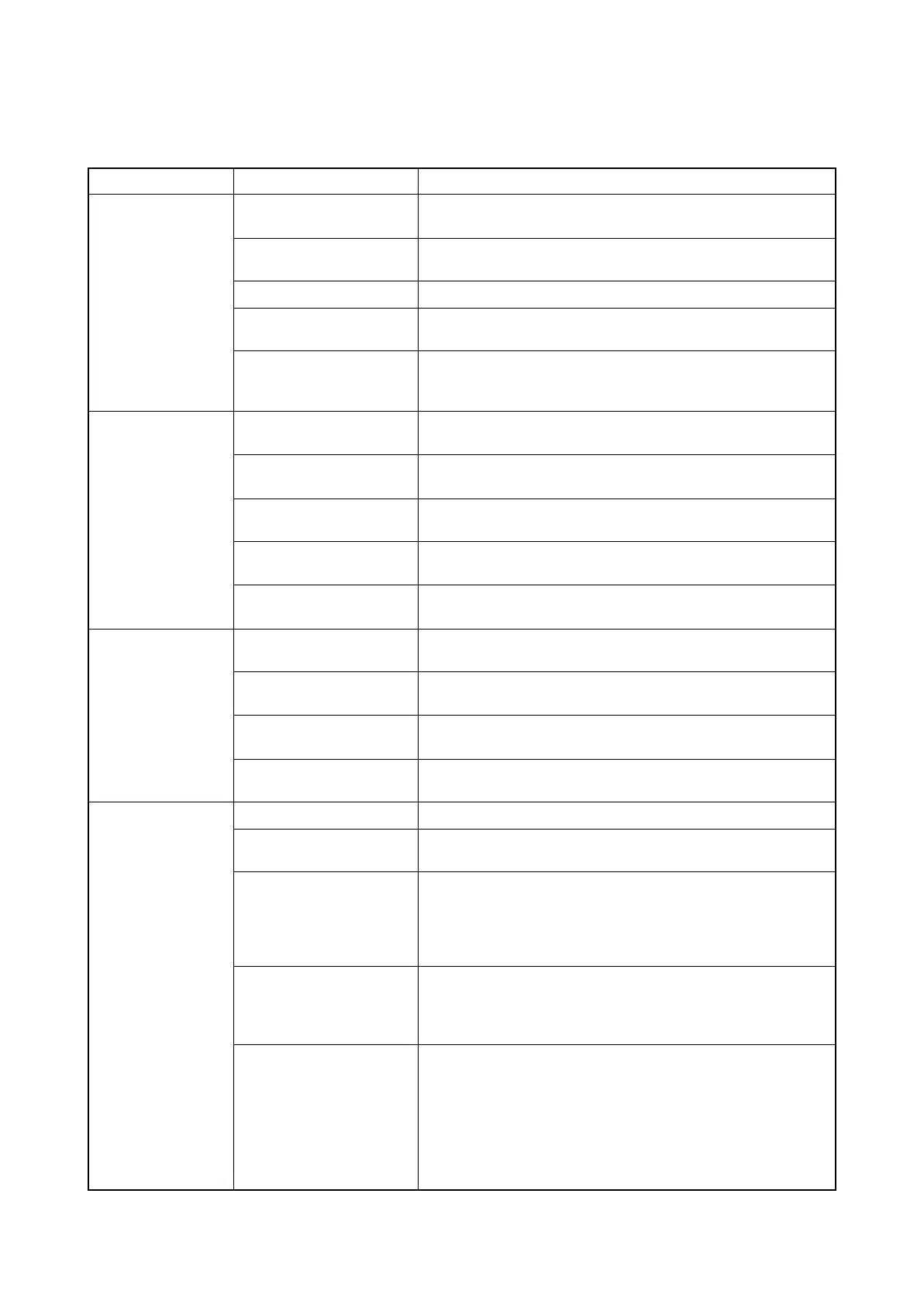

2KA

1-4-61

1-4-4 Electric problems

Troubleshooting to each failure must be in the order of the numbered symptoms.

Problem Causes Check procedures/corrective measures

(1)

The machine does

not operate when the

main power switch is

turned on.

1. The power cord is not

plugged in properly.

Check the contact between the power plug and the outlet.

2. No electricity at the

power outlet.

Measure the input voltage.

3. Broken power cord. Check for continuity. If none, replace the cord.

4. Defective main power

switch.

Check for continuity across the contacts. If none, replace the main

power switch.

5. Defective power source

PWB.

With AC present, check for 24 V DC at YC7-1, YC7-2 and 5 V DC

at YC7-6 on the power source PWB. If none, replace the power

source PWB.

(2)

Registration motor or

duplex motor does

not operate.

1. Poor contact in the con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

2. Defective drive transmis-

sion system.

Check if the rollers and gears rotate smoothly. If not, grease the

bushings and gears. Check for broken gears and replace if any.

3. Defective motor. Run maintenance item U030 and check if the motor operates. If

not, replace the motor.

4. Defective feed PWB. Run maintenance item U030 and check if the motor operates. If

not, replace the feed PWB.

5. Defective engine PWB. Run maintenance item U030 and check if the motor operates. If

not, replace the engine PWB.

(3)

Toner container

motor does not oper-

ate.

1. Poor contact in the con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

2. Defective drive transmis-

sion system.

Check if the rollers and gears rotate smoothly. If not, grease the

bushings and gears. Check for broken gears and replace if any.

3. Defective motor. Run maintenance item U135 and check if the motor operates. If

not, replace the motor.

4. Defective engine PWB. Run maintenance item U135 and check if the motor operates. If

not, replace the engine PWB.

(4)

Front fan motor or

container fan motor

does not operate.

1. Broken fan motor coil. Check for continuity across the coil. If none, replace the fan motor.

2. Poor contact in the con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

3. Defective fan motor. Run maintenance item U037 and check if the fan motor operates

when the following terminals on the PWB goes low. If not, replace

the corresponding fan motor.

Front fan motor: YC2-1 on the main front PWB

Container fan motor: YC7-2 on the main front PWB

4. Defective main front

PWB.

Run maintenance item U037 and check if following terminals on

the main front PWB goes low. If not, replace the main front PWB.

Front fan motor: YC2-1 on the main front PWB

Container fan motor: YC7-2 on the main front PWB

5. Defective engine PWB. Run maintenance item U037 and check if following terminals on

the engine PWB goes low. If not, replace the engine PWB.

Front fan motor: YC18-A8 on the engine PWB

Container fan motor: YC18-B1 on the engine PWB

Loading...

Loading...