BOOM TMS700E SERVICE MANUAL

4-18 Published 01-29-2015, Control # 512-01

Removal and Installation

Removal and installation of the telescope cylinder from the

boom is described under disassembly and assembly of the

boom. Refer to Maintenance, page 4-2.

Disassembly and Assembly

Disassembly and assembly procedures of the telescope

cylinder and control valve are provided in Hydraulic System,

page 2-1 under Cylinders and Valves respectively.

LIFT CIRCUIT

Description

The boom lift circuit consists of the lift hydraulic remote

controller, lift directional control valve, holding valve, and the

lift cylinder. These components enable the boom to be raised

or lowered to various degrees of elevation ranging from -3 to

+78 degrees from horizontal.

The lift directional control valve is the closed spool type and

is described under Valves, page 2-19.

Refer to Hydraulic Remote Control Valve, page 2-34 for a

complete description of the hydraulic remote controller.

The lift cylinder has a 30.48 cm (12.0 in) bore and is the

double acting type. Dirt and other foreign material is

prevented from entering the cylinder and causing internal

damage by a wiper seal during rod retraction. Oil Seals on

both the piston and cylinder head prevent internal and

external hydraulic oil leakage. Refer to Lift Cylinder, page 2-

54 for a complete description of the lift cylinder.

The holding valve is a balanced poppet type hydraulic valve.

It is threaded into the port block which is an integral portion of

the lift cylinder barrel. The holding valve functions when

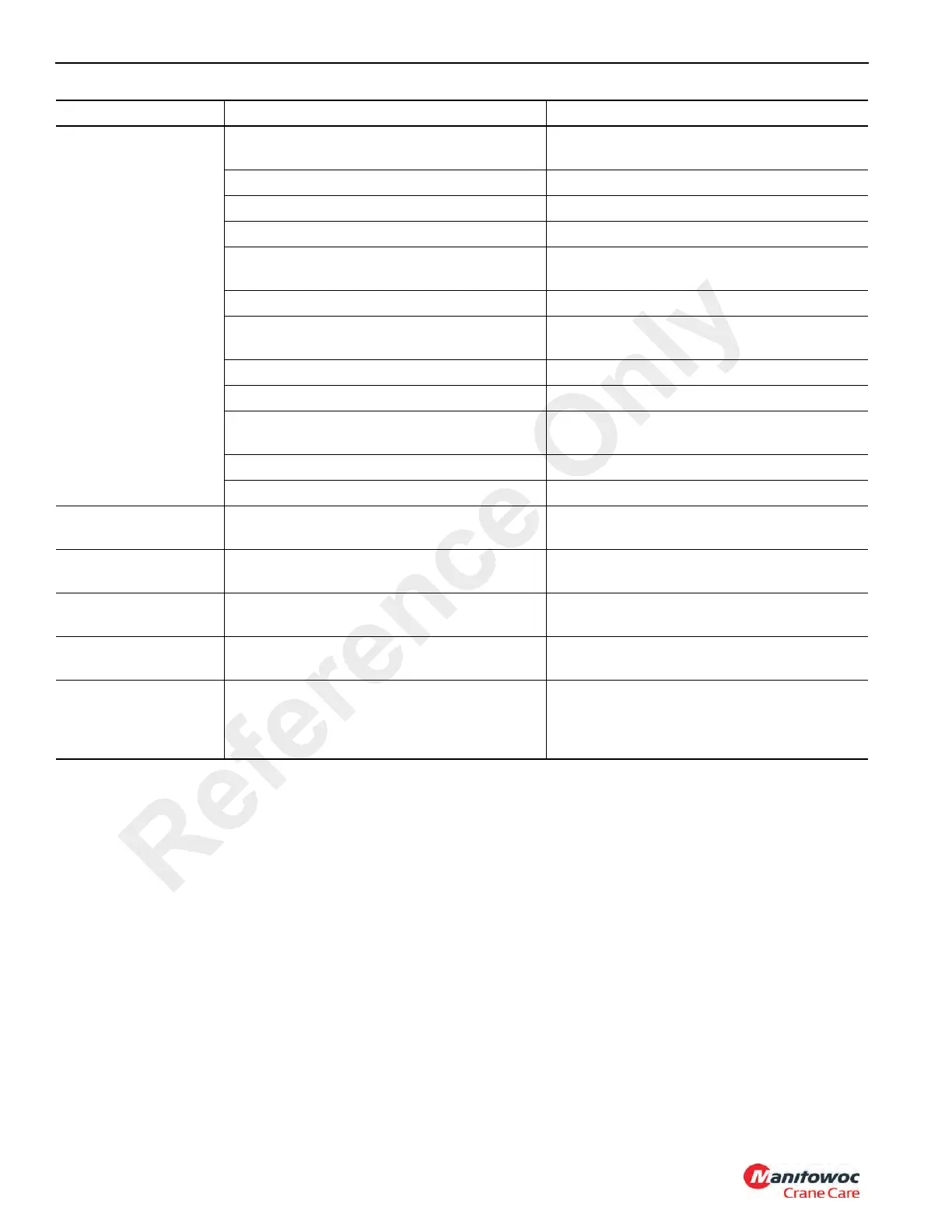

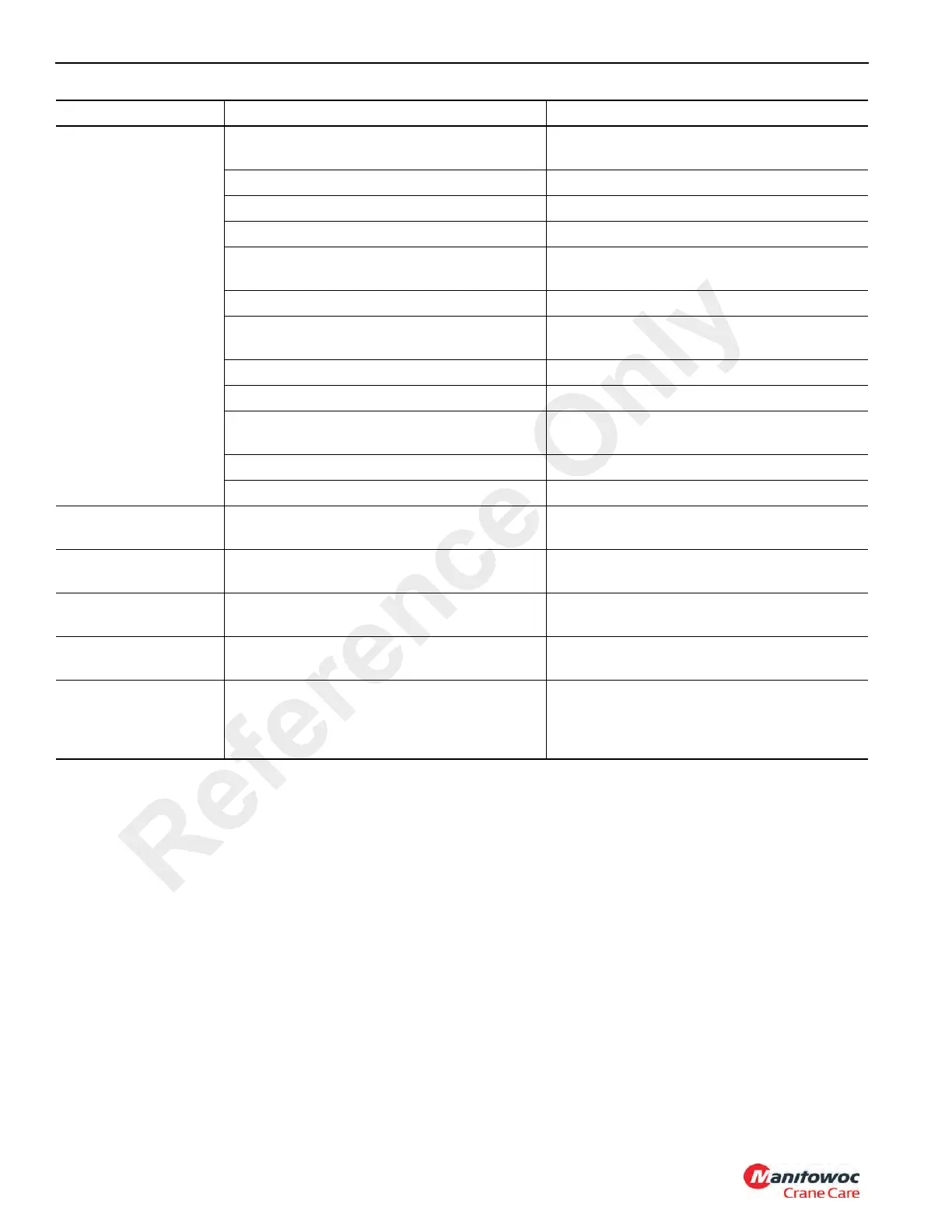

4. Telescope cylinder

will not retract.

a. Low hydraulic oil level. a. Check for leaks. Repair any found.

Replenish oil to proper level.

b. Relief valve damaged. b. Repair or replace relief valve.

c. Excessive load. c. Reduce load. (Refer to load chart).

d. Inoperative check valve. d. Replace check valve.

e. Clogged hose and fittings. e. Replace hose or fittings. (Refer to

Grove Parts Manual).

f. Broken valve spool. f. Replace valve section.

g. Broken piston(s). g. Replace piston(s) and all cylinder

seals.

h. Damaged piston seals. h. Replace all cylinder seals.

i. Bent boom section(s). i. Replace damaged boom section(s).

j. Broken hydraulic pump coupling. j. Replace broken hydraulic pump

coupling.

k. Worn or damaged hydraulic pump. k. Repair or replace pump.

l. Broken hydraulic pump shaft. l. Replace pump shaft.

5. Section 2 will not

extend.

a. Right side check valve blocked. a. Readjust, repair, or replace valve.

6. Section 2 will not

retract.

a. Right side check valve closed. a. Readjust valve

7. Section 3 will not

extend.

a. Left side check valve is closed a. Readjust valve

8. Section 2 retracts

before Section 3.

a. Right side

check valv

e is open or

hosed backwards.

a. Install hoses properly

9. Section 3 extends

only a short

distance, then

stops.

a. Left check valve is open or hosed

backwards

a. Install hoses properly.

SYMPTOM PROBABLE CAUSE SOLUTION

Reference Only

Loading...

Loading...