Grove Published 01-29-2015, Control # 512-01 8-37

TMS700E SERVICE MANUAL UNDERCARRIAGE

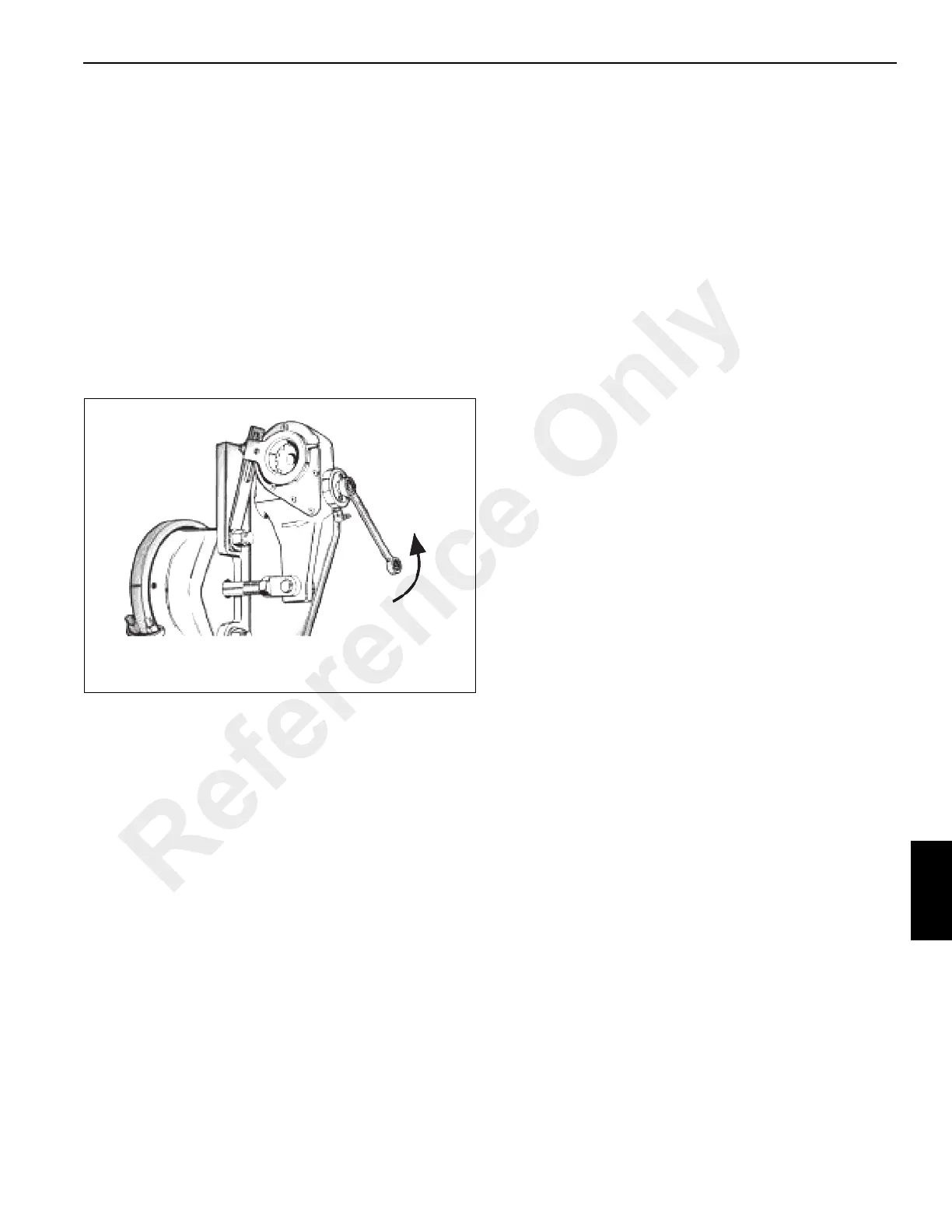

5. Using a pry bar, move the slack adjuster so that the

linings contact the drum. Measure the distance between

the same points as in step 4. This dimension is “Y” in

(Figure 8-38).

6. Subtract dimension “X” from dimension “Y”. The

difference should be 12.7 to 15.9 mm (0.5 to 0.625 in). If

the stroke falls within these limits, no adjustment is

required. If it falls outside these limits, proceed to step 7.

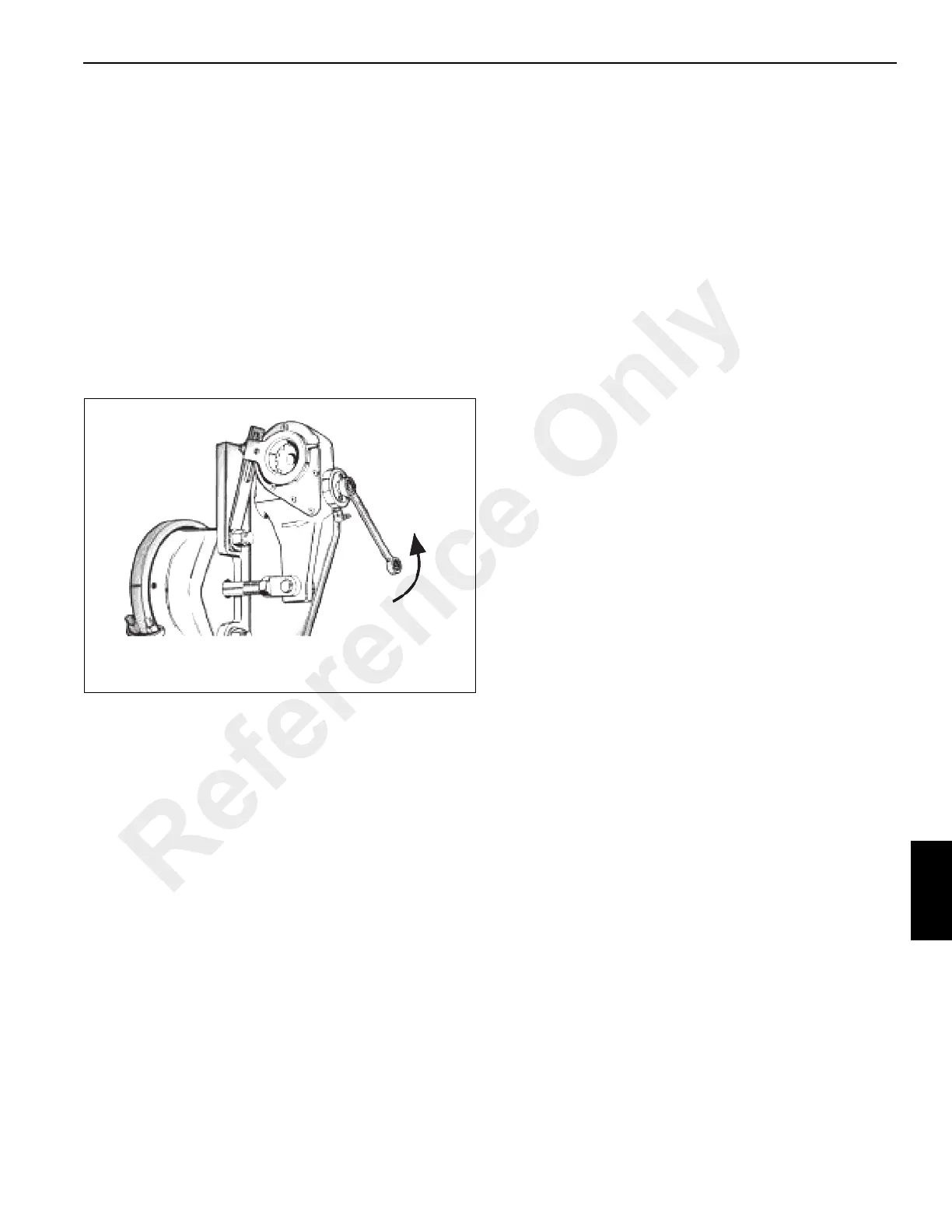

7. Rotate the adjusting hex approximately 1/8 turn in the

direction required and re-measure the stroke. Continue

this process until the stroke is within limits. A minimum of

17.6 Nm (13 lb-ft) of torque is required to turn the hex

and overcome the internal clutch. A ratcheting noise will

be heard. Do not use an impact wrench or internal

damage will occur (Figure 8-39).

8. With brakes released, check installation indicator

Figure 8-38 and Figure 8-39 to determine proper

adjustment.

9. If installation indicator is not positioned properly, refer to

Figure 8-39. Loosen fastener holding indicator to anchor

bracket, rotate indicator as required and retighten

fastener.

10. Uncage spring brake if so equipped.

REAR BRAKES

Description

Brakes

The rear brakes are air actuated and cam operated. Each

shoe, which is steel fabricated, employs two 19 mm (0.75 in)

tapered block liners. The shoes are mounted on individual

anchor pins and supported by open type spiders. Automatic

slack adjusters maintain proper adjustment of the push rod

stroke and lining to drum clearance.

The brake actuator is a conventional brake air chamber with

an emergency (parking) brake spring mechanism

incorporated into the air brake chamber. The brake chamber

has an aluminum body and pressure plate with a steel non-

pressure plate that houses a service/emergency diaphragm,

piston, and two springs.

Spring Brake Actuator

The spring brake actuator, which is the upper part of the air

brake chamber, is spring applied and air released. When an

air pressure of 4.82 bar (70 psi) or more is applied against

the piston, the spring is compressed and braking is done with

the service brakes. When the air pressure is removed, the

spring pushes against the piston and diaphragm plate to

apply the brake. Internal venting works in conjunction with a

one-way breather cap that allows system air to fill the

vacuum behind the piston to keep out atmospheric air and

contamination. The unit is equipped with a manual caging

bolt to permit safe handling and service work.

Reference Only

Loading...

Loading...