Grove Published 01-29-2015, Control # 512-01 8-21

TMS700E SERVICE MANUAL UNDERCARRIAGE

WHEELS AND TIRES

Description

The following tire size is available for the axles:

• Front axle; size 445/65R22.5

• Rear axle: size 315/80R22.5.

NOTE: Tire diameter, width, and weight may vary slightly

depending upon the manufacturer.

Tires are designed to operate with a certain sidewall

deflection or bulge. Correct air pressures ensures proper

deflection which, in turn ensures proper traction, flotation,

support of load and prevents excessive flexing of the tire.

Overinflation increases rim stresses which results in lower

rim life.

Inflate tires to the pressure specified on the tire inflation

decal on the crane.

Unmatched tires on either tandems will cause wear, scuffing,

and possible damage to drive units. It is recommended that

tires be matched to within 3.2 mm (0.13 in) of the same

rolling radius and 19.0 mm (0.75 in) of the same rolling

circumference.

In addition to matching individual tire rolling radii and

circumference, the total tire circumference of one driving axle

should match the other driving axle.The result will be

satisfactory axle lubricant temperatures.

Maintenance

Mounting the Wheels on the Front Axle

NOTE: Do not lubricate the wheel studs or lug nuts or the

wheel face or the hub. On aluminum wheels,

lubricate the wheel pilot or hub pads only with an

antiseize compound or synthetic lubricant with

teflon. Do not lubricate wheel or hub faces.

1. Raise the crane on outriggers so the front wheels are off

the ground.

2. Generously coat the wheel pilot or hub pads with

antiseize compound. Do not apply antiseize compound

to the face of the wheel or the hub.

3. Place the wheel assembly on the mounting studs. Take

care not to damage the studs.

4. Install hub cover if applicable.

5. Install the lug nuts and tighten them until they are just

snug. Rotate the wheel while installing each nut so the

nut being tightened is in the top position. Do not lubricate

the nuts or studs.

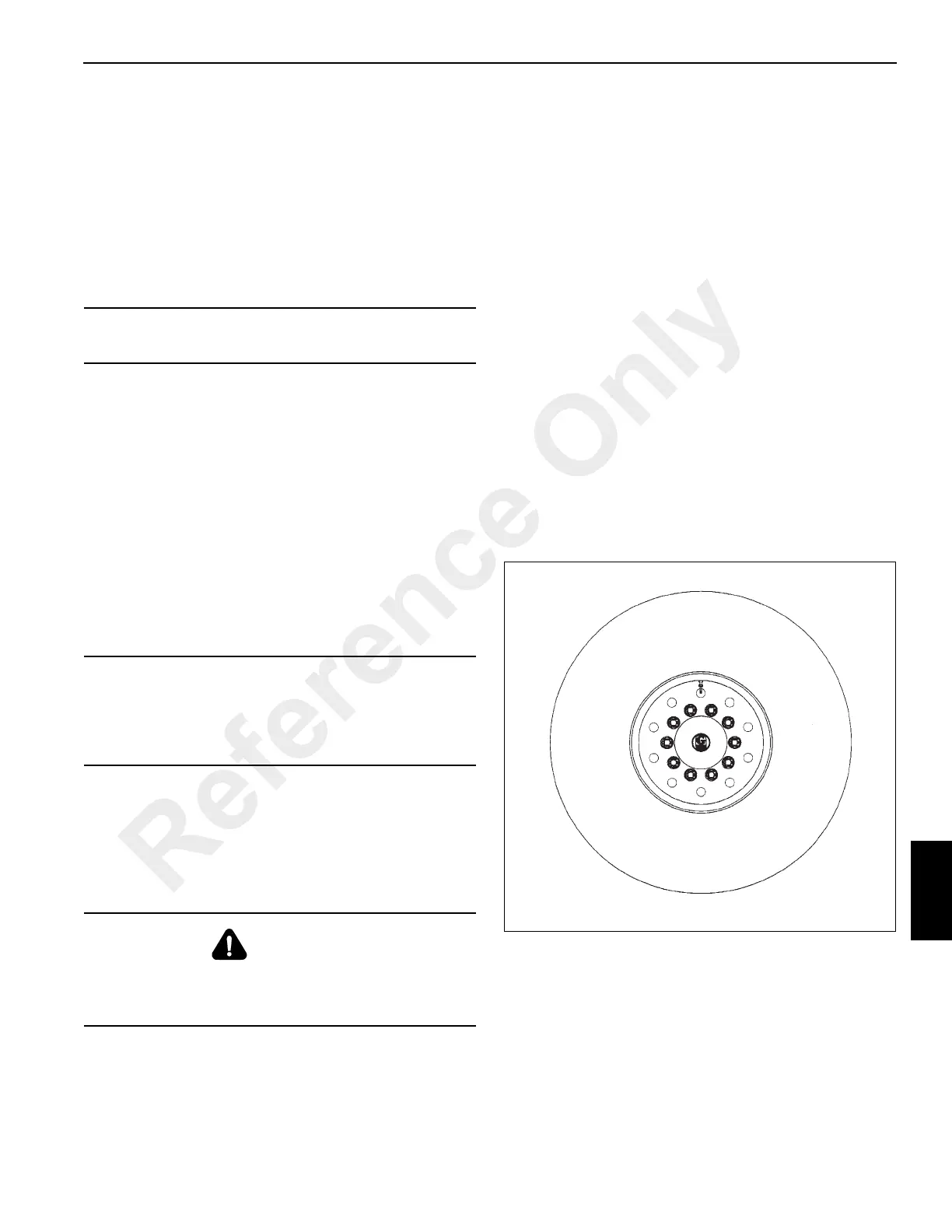

6. Tighten the lug nuts in the sequence shown to a

preliminary torque of 68 Nm (50 lb-ft) (see Figure 8-13).

7. Keep tightening the lug nuts in the sequence shown until

all 10 are torqued to 610 to 678 Nm (450 to 500 lb-ft)

(see Figure 8-13).

8. Install lug nut covers on lug nuts.

9. Lower the crane onto its tires. Retract and stow the

outrigger assemblies and the floats.

10. Road-test the tire, then retorque to 610 to 678 Nm (450

to 500 lb-ft).

Maintain proper torque on wheel lugs and check for proper

wheel mounting. Retorque the lug nuts 80 to 160 km (50 to

100 miles) after the wheels are removed and reinstalled. This

will reseat the lug nuts. Check the torque every 800 km

(500 miles) thereafter.

CAUTION

Do not mix tires or rims from different manufacturers.

CAUTION

Do not install the largest tires on one driving axle and the

smallest on the other driving axle. This will cause axle

“fight” and high lubricant temperatures resulting in

premature lubricant breakdown and costly axle service.

DANGER

Do not dismount or mount tires on rims without proper

training. High pressures can cause tire and rim parts to fly

apart with explosive force and cause injury or death.

Reference Only

Loading...

Loading...