Grove Published 01-29-2015, Control # 512-01 7-19

TMS700E SERVICE MANUAL POWER TRAIN

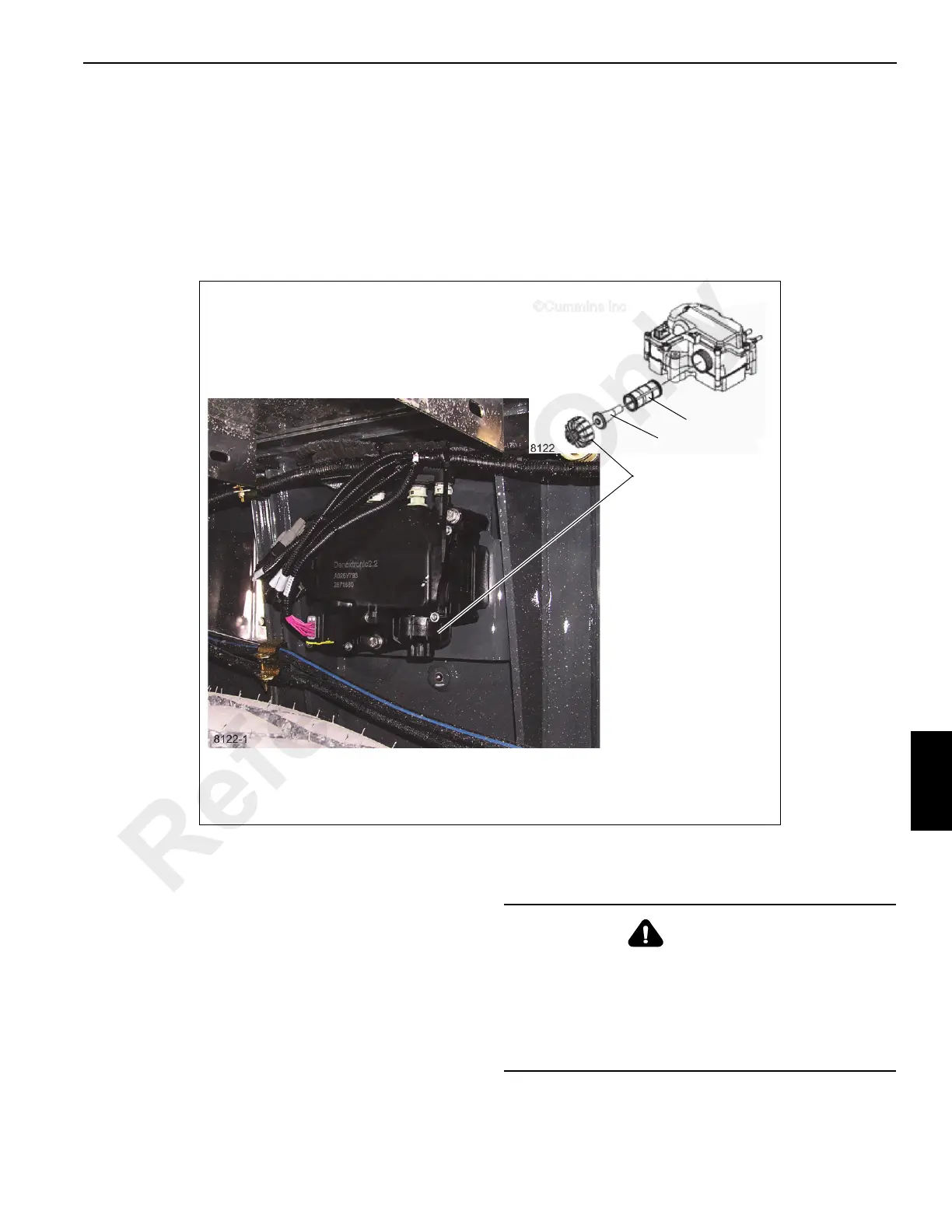

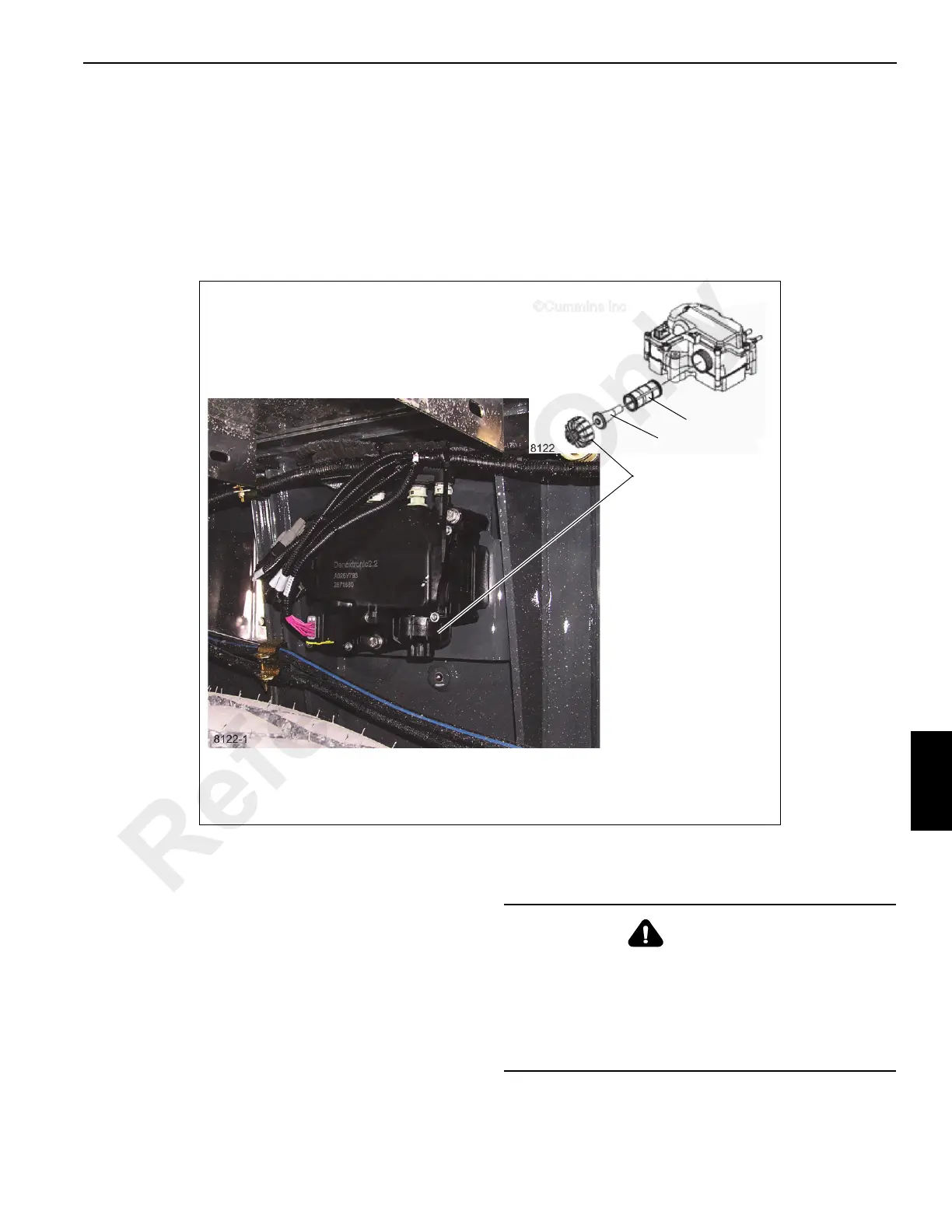

DEF Dosing Unit Filter

The DEF dosing unit filter is a 10-micron filter designed to

prevent foreign objects, that may be suspended in the DEF,

from entering the dosing system.

Debris can cause permanent damage and premature failure

to either the aftertreatment DEF dosing unit or the

aftertreatment DEF dosing valve.

The filter should be replaced every 200,000 miles or 4500

hours of crane operation.

The aftertreatment DEF dosing unit filter consists of the

following components:

(1) Aftertreatment DEF Dosing Unit Filter Cap

(2) Aftertreatment DEF Dosing Unit Filter Equalizing Element

(3) Aftertreatment DEF Dosing Unit Filter Element.

Initial Check

Inspect the area around the seal and vent of the

aftertreatment DEF dosing unit filter cap for signs of leakage.

DEF leaks leave a white deposit. If deposits are found, see

the Clean and Inspect for Reuse section in this procedure.

Preparatory Steps

3

2

1

DEF Dosing Unit

1. DEF Filter Cap

2. DEF Filter Equalizing Element

3. DEF Filter Element

WARNING

DEF contains urea. Do not get the substance in your

eyes. In case of contact, immediately flush eyes with large

amounts of water for a minimum of15 minutes. Do not

swallow. In the event the DEF is ingested, contact a

physician immediately. Reference the Materials Safety

Data Sheet (MSDS) for additional information.

Reference Only

Loading...

Loading...