Grove Published 01-29-2015, Control # 512-01 2-67

TMS700E SERVICE MANUAL HYDRAULIC SYSTEM

3. Place the rod on a clean table

4. Install the head and then the piston onto the rod noting

the proper orientation of each component. Torque the

piston locknut.

5. Install the setscrew in the head.

6. Brush piston seals and head seals with hydraulic oil.

7. Install the rod assembly into the barrel. Alignment is

critical. Watch the seals as they pass into the barrel to

ensure that they are not nicked or cut.

8. Slide the head into the barrel and align the retaining ring

drilled hole on the head with the barrel mill slot. Insert

the blunt, curved end of the retaining ring into the hole

and slowly work the head around, using the spanner

wrench until no part of the ring protrudes from the slot.

9. Install the remaining port plugs.

10. Pressurize and cycle the cylinder with hydraulic oil

pressure. Test the cylinder at 241 bar (3500 psi). Check

for proper operation and any leakage. Make repairs as

needed.

OUTRIGGER EXTENSION CYLINDER

Description

The four extension cylinders (Figure 2-52) have 6.4 cm (2.5

in) diameter bores. Each cylinder has a retracted length of

213.3 cm (84.0 in) from the center of the rod bushing to the

center of the barrel bushing. Each cylinder’s extended length

is 396.72 cm (156.19 in). The stroke of each cylinder is

183.36 cm (72.19 in). A wiper ring prevents foreign material

from entering each cylinder. O-rings and other seals prevent

internal and external leakage.

The cylinder weighs approximately 42 kg (92 lb).

Maintenance

Disassembly

NOTE: Any maintenance requiring disassembly of the

cylinders should include replacement of all seals

and rings. A seal kit will supply the required items.

1. Clean away all dirt from the head. Place protective

padding around the rod near the head to prevent

damaging the chrome during head removal. Using a

spanner wrench, unscrew the head from the barrel.

2. Rapidly pull the rod against the head to free it. Remove

rod and attached parts from the barrel.

NOTE: Cover the barrel opening to avoid contamination.

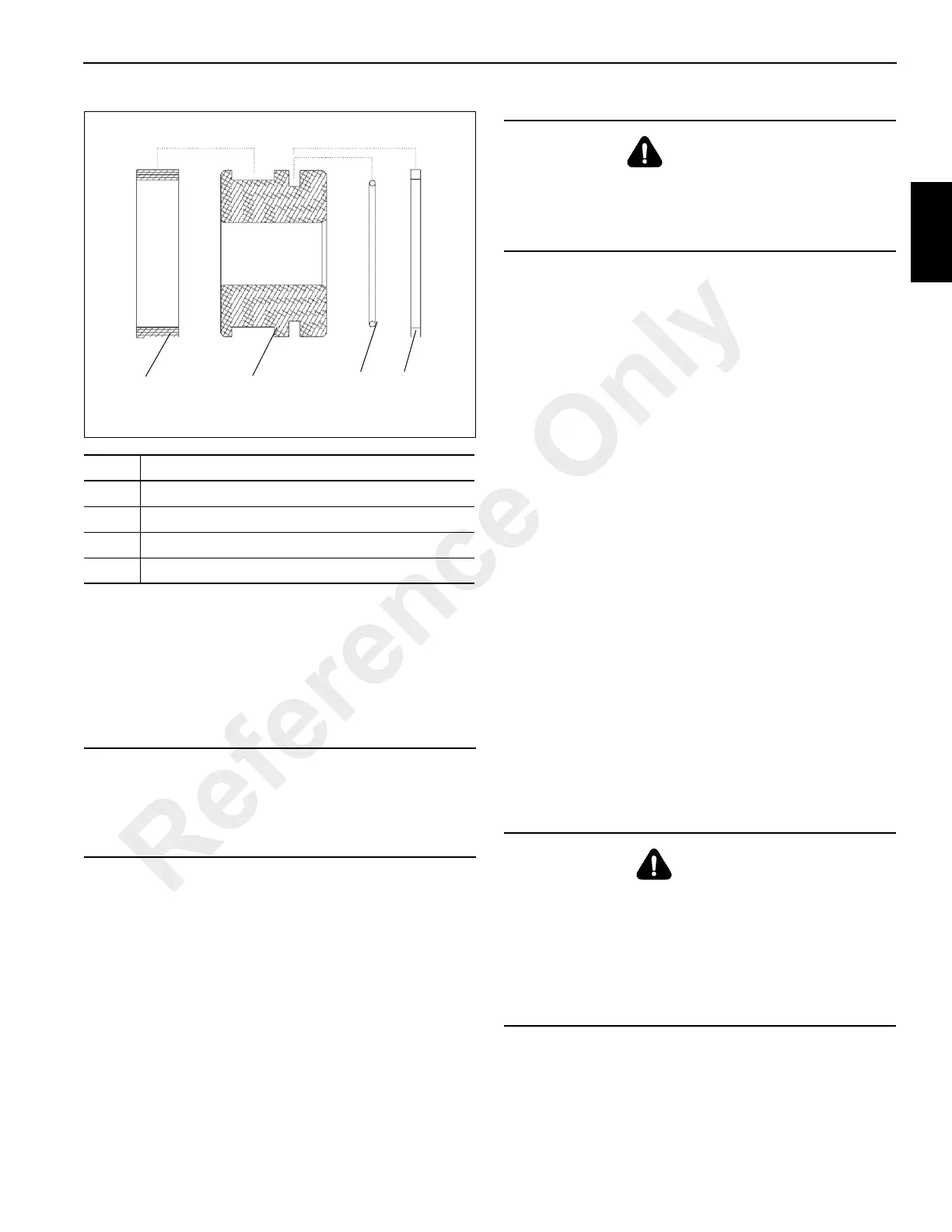

Item Description

1 Wear Ring

2Piston

3 O-ring (Energizer)

4 Piston Seal

CAUTION

Ensure there are no rags or other contaminants left in the

cylinder barrel before installing rod assembly. Lubricate

the barrel ID with hydraulic oil to ease the rod assembly

installation.

WARNING

Before testing, ensure all fittings, hoses, ball valves, and

pump components are rated higher than test pressures.

Do not use air pressure to cycle or pressurize the cylinder.

Failure to do so could result in personal injury or death.

DANGER

Do not use air pressure to remove the rod. Use only a

source of controlled hydraulic oil pressure if the rod is

hard to move.

CAUTION

Exercise extreme care when handling or setting down the

rod. Damage to the rod surface may cause unnecessary

maintenance and expense.

Reference Only