Grove Published 01-29-2015, Control # 512-01 1-11

TMS700E SERVICE MANUAL INTRODUCTION

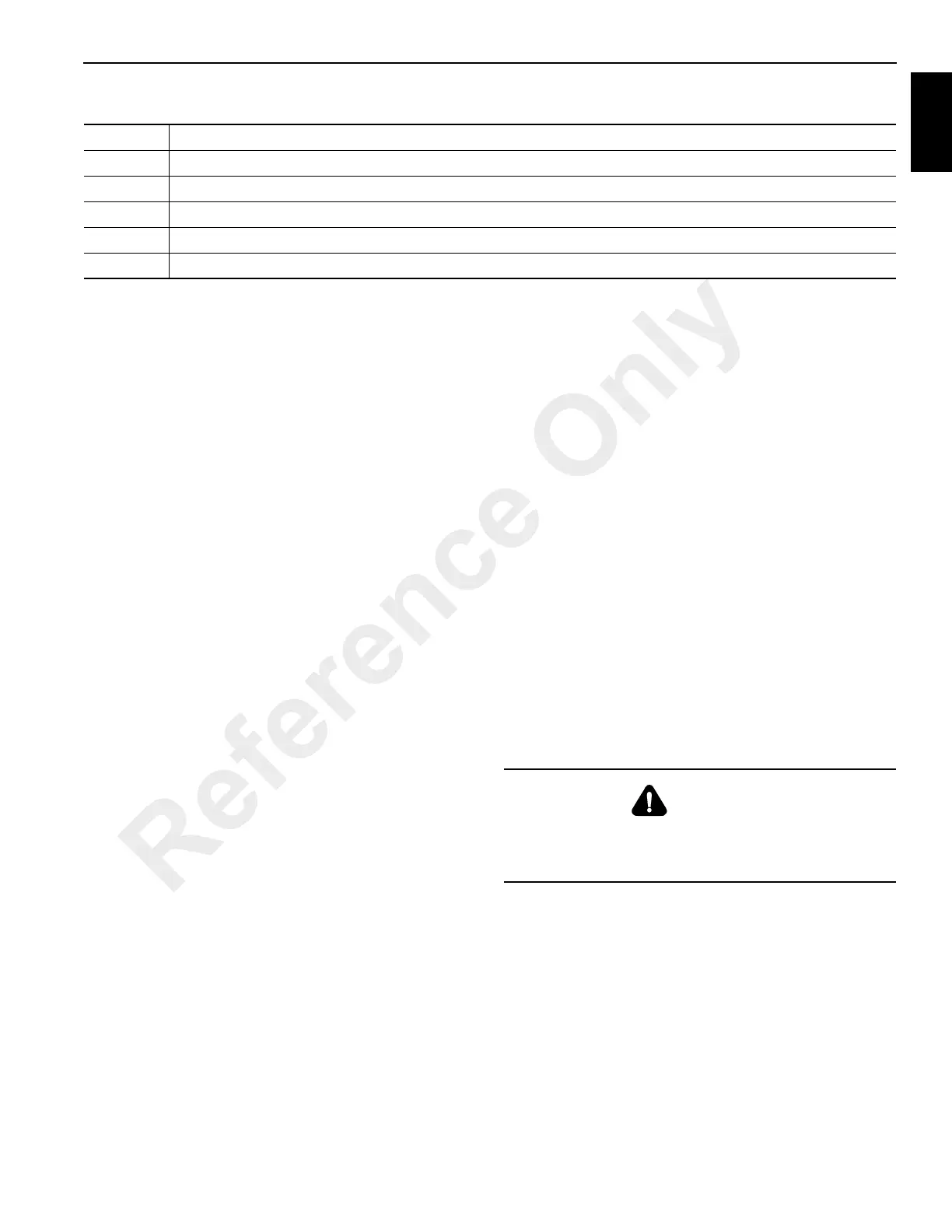

Table 1-2

Electrical System

Connectors, Harnesses, Wires, and Cables

Visually inspect all electrical harnesses, cables, and

connectors every month or 250 hours for the following:

• Damaged, cut, blistered, or cracked insulation.

• Exposed bare wires.

• Kinked or crushed wires and cables.

• Cracked or corroded connectors, battery terminals, and

ground connections.

If any of the above conditions exist, evaluate and replace as

necessary.

The climate in which the crane operates affects the service

life of the electrical components. The climate zones are

defined in Table 1-2. Recommended replacement of harness

and cables is as follows:

• Climate zone C after 10,000 hours of service.

• Climate zones A and C with high ambient temperatures

and duty cycles after 8,000 hours of service.

• Climate zones D and E after 10,000 hours of service.

• Salt water conditions after 8,000 hours of service.

Fatigue of Welded Structures

Experience has shown that highly stressed welded

structures when repeatedly subjected to varying stresses

caused by twisting, shock, bending, and intentional and/or

unintentional overloads, often become subject to weld

cracking which may be attributed to fatigue of the welded

joint. This condition is not uncommon in construction

equipment.

Equipment should be periodically inspected for evidence of

weld fatigue. The frequency of these inspections should be

commensurate with the age of the equipment, the severity of

the application, and the experience of the operators and

maintenance personnel.The following are known high stress

areas applicable to Grove machines, and a visual inspection

of these areas should be made part of an owner’s planned

preventive maintenance program:

• Power Telescope Boom - wear pad retaining structures,

hydraulic cylinder attaching points, boom pivot shaft

retaining structures.

• Outrigger pads, beams, boxes and attachment

structures.

• Main frames - generally in the area of doubler plates and

crossmembers; at the junction of front and rear frame

members on truck cranes.

• Turntable bearing connection (where bearing is welded

to the crane superstructure or chassis).

• Counterweight support structures.

• Chassis axle and suspension mounting structures.

• Hydraulic cylinder end connections.

The above is provided only as a guide, and your inspection

plan should not be limited to the areas listed. A thorough

visual inspection of all weldments is good practice.

Anyone requiring more detailed inspection instructions and/

or repair procedures may request same by contacting your

distributor.

Loctite®

Always follow the directions on the Loctite container as not

all Loctite types are suitable for all applications. Various

types of Loctite are specified throughout the Service Manual.

The following types of Loctite brand adhesives are available

from the Manitowoc Crane Care Parts Department or your

local distributor.

Application of Medium Strength Loctite

NOTE: The fastener may be re-used; the adhesive may be

re-applied over cured adhesive residue.

Zone Classification

A Tropical Moist: All months average above 18° C. Latitude 15° - 25° North and South

B Dry or Arid: Deficient precipitation most of the year. Latitude: 20° - 35° North and South

C Moist Mid-Latitude: Temperature with mild winters. Latitude: 30° - 50° North & South

D Moist Mid-latitude: Cold winters. Latitude 50° - 70° North & South

E Polar: Extremely cold winters and summers. Latitude: 60° - 75° North & South

DANGER

Loctite type adhesives contain chemicals that may be

harmful if misused. Read and follow the instructions on

the container.

Reference Only

Loading...

Loading...