HOIST AND COUNTERWEIGHT TMS700E SERVICE MANUAL

5-2 Published 01-29-2015, Control # 512-01

3. Tag and disconnect the electrical wires to the hoist

rotation indicator sensor box.

4. Tag and disconnect the electrical wires to the hoist motor

control valve.

5. Remove the hoist mounting nuts, bolts, washers, and

shims (if shims are used, mark their location).

NOTE: The GHP 30A model hoist assembly, less the

cable, weighs approximately 650 kg (1430 lb). If

there is only one hoist on the superstructure, there

will be an extra counterweight plate weighing about

672 kg (1480 lb) in place of the auxiliary hoist.

6. Using an adequate lifting device, remove the hoist from

the crane.

Installation

1. Ensure the mounting plate and hoist pads are clean and

free from debris and the hoist has not been damaged

during handling.

2. With the hoist supported by a suitable lifting device,

position the hoist on the mount.

3. Check the hoist to boom alignment according to Hoist to

Boom Alignment, page 5-6.

4. Place a level between the boom pivot shaft bushings.

5. Place a level across the top of the hoist drum and

determine if the hoist is sitting in the same plane in

relation to the level positioned between the boom pivot

shaft bushings.

6. With the hoist level, check to determine if all the hoist

mounting pads are in contact with the mounting plate by

rocking the hoist.

7. Keeping the hoist level, use a feeler gauge to determine

the amount of gap existing between the pads and the

mounting plate.

8. Add shims to satisfy any existing gaps. Altering the shim

thickness to fit a tapering gap is acceptable. Install the

bolts, washers, and nuts. Tighten bolts; refer to

Fasteners and Torque Values, page 1-12 for the torque

value for the hoist mounting bolts.

9. Remove the lifting device from the hoist.

10. Connect the hydraulic lines to the hoist. Ensure the

proper lines are connected to the correct ports as

marked during removal.

11. Connect the electrical wires to the hoist motor control

valve as marked during removal.

12. Connect the electrical wires to the hoist drum rotation

indicator sensor box as tagged during removal.

13. Install the cable, following the procedures outlined under

Installing Cable on the Hoist, in the Operator’s Manual.

Functional Check

1. Attach a test weight to the hook and raise and lower the

load several times.

2. Check the hoist for smooth operation of the hoist motor

and brake system.

3. Ensure the hydraulic connections are secure and free

from leaks.

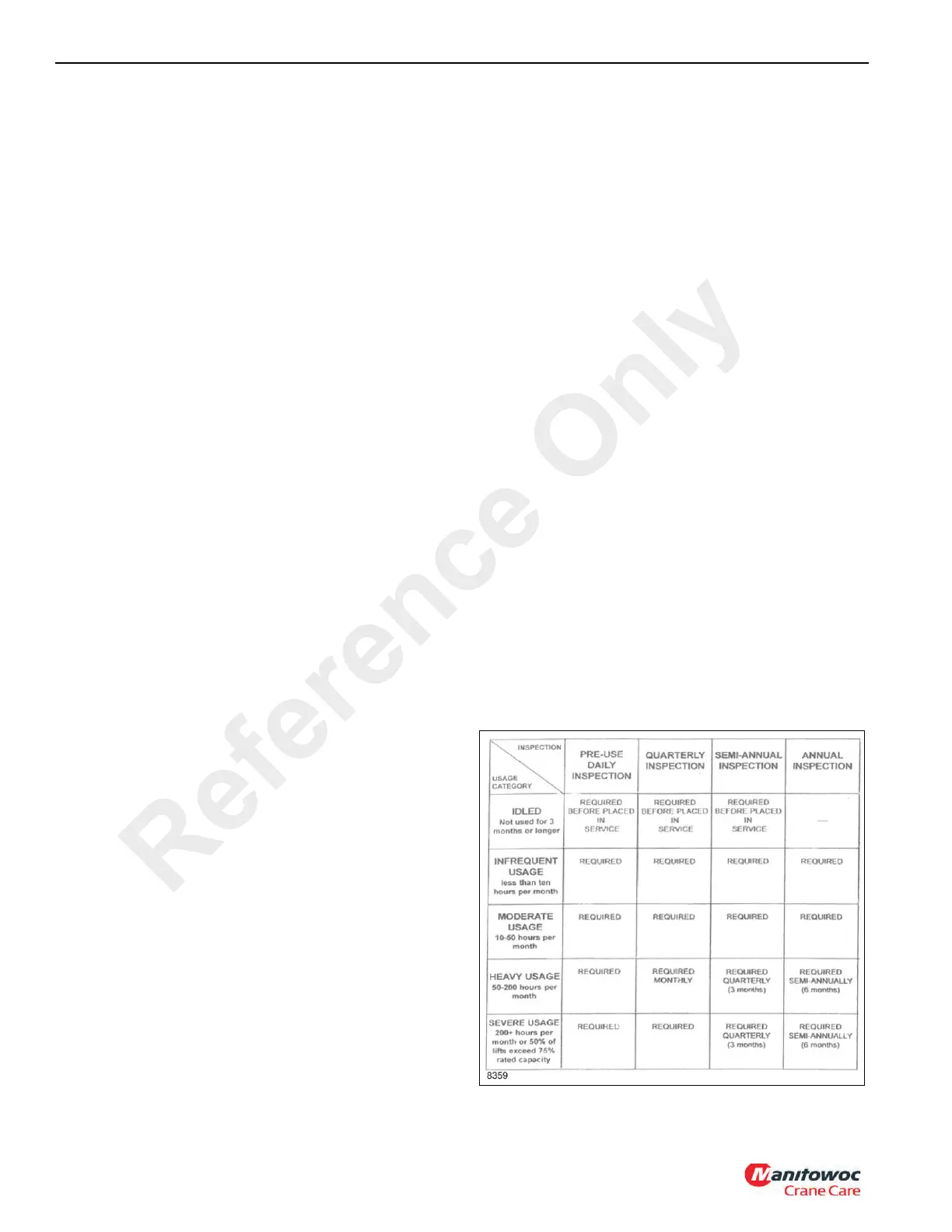

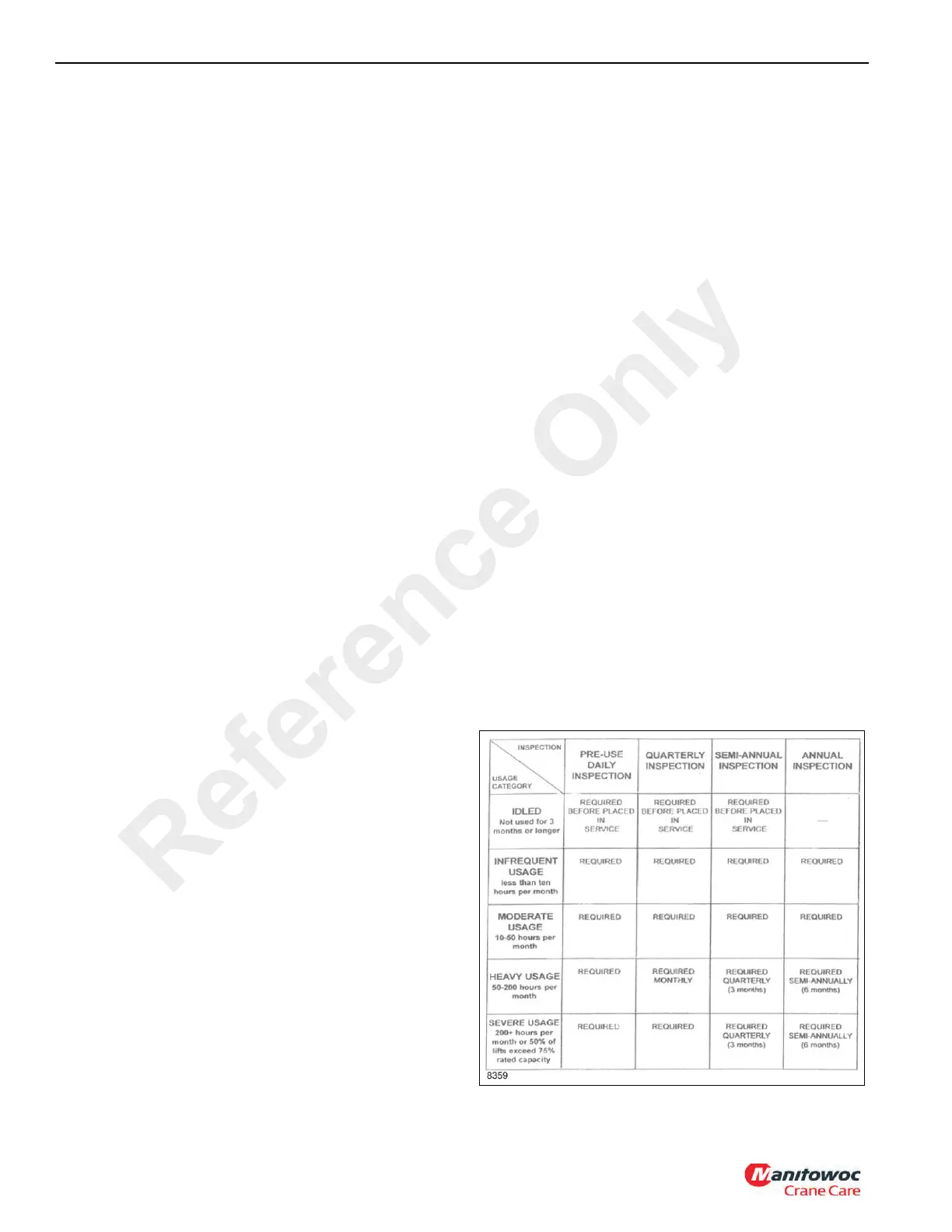

Usage and Inspection

Inspection procedures for hoists are divided into five general

categories based upon their usage or duty cycle, which in

turn determines appropriate intervals for inspections. The

usage categories must be assigned by the crane user on a

consistent crane-by-crane basis. The five crane/hoist usage

categories are as follows:

Idled - The crane/hoist has not been used for three months.

Infrequent Usage - The crane/hoist is used less than ten

hours per month based on a three month average

Moderate Usage - Crane/hoist used 10 - 50 hours per month

based on a three month average.

Heavy Usage - Crane/hoist used 50 - 200 hours per month.

Severe Usage - Crane/hoist is operated more than 200

hours per month OR where 50% of the lifts exceed 75% of

the rated capacity for the hoist.

The following chart lists the inspections that are required for

each type of usage category.

Reference Only

Loading...

Loading...