Grove Published 01-29-2015, Control # 512-01 2-7

TMS700E SERVICE MANUAL HYDRAULIC SYSTEM

• Hydraulic hose assemblies operating in climate zone “C”

are recommended to be replaced after 8000 hours of

service life.

• Hydraulic hose assemblies operating in climate zones

“A” or “B” with high ambient temperatures, could see

hose service life reduced by 40% - 50%. Therefore, it is

recommended to replace these hoses after 4000 - 5000

hours of service life.

• Hydraulic hose assemblies operating in climate zones

“D” and “E” cold climates should expect a degrade of

mechanical properties such as elasticty.Therefore it is

recommended that these hoses be inspected and

addressed accordingly.

SUPPLY PRESSURE AND RETURN CIRCUIT

Description

The supply pressure and return circuit is made up of several

circuits which route hydraulic oil from the three hydraulic

pumps to the directional control valves for the individual

operating circuits. The supply pressure and return circuit

consists of the reservoir and integral filter, three hydraulic

pumps, a hydraulic oil cooler, and a 5-port hydraulic swivel.

Refer to Hydraulic Pumps, page 2-14 in this section for

descriptions and maintenance instructions for each hydraulic

pump. Refer to Swing System, page 6-1 for description and

maintenance instructions for the 5-port hydraulic swivel.

The supply pressure and return circuit uses Ports 1, 3, and 4

for pump supply and the dual Port 2 for return. Each

operating circuit’s description and components begin with

the circuit’s directional control valve.

Hydraulic Reservoir and Filter

The reservoir (Figure 2-2), attached to the right side of the

carrier frame, has a capacity of 564 liters (149 gal) total, 507

liters (134 gal) to the full mark. The all-steel reservoir has an

internally mounted full-flow filter and integral baffles that help

cool the hydraulic oil and prevent hydraulic oil foaming.

Hydraulic oil flows through the manifold at the lower rear of

the reservoir to the three hydraulic pumps. Almost all of the

return flow goes through the filter at the top of the reservoir.

The return line that goes directly into the reservoir (instead of

through the filter) is from the No. 5 port (drain) of the 5-port

swivel.

A magnetized drain plug in the bottom of the reservoir

collects metal particles from the hydraulic oil if it becomes

contaminated.

A sight gauge is located on the side of the reservoir to

indicate hydraulic oil level.

A filler cap on the top of the reservoir is for filling the

reservoir. The filler cap includes a strainer for catching

contaminants and gaskets to prevent leaking. A breather cap

(vent) is located on top of the reservoir to allow air to enter or

exhaust from the reservoir. It is most important that the

breather be kept clean to prevent damage to the reservoir.

A large access cover on the top of the reservoir provides

access for cleaning. The cover is secured to the top of the

reservoir with a band clamp and has a gasket to prevent

leaking.

An oil temperature gauge is located on the end of the

reservoir to indicate oil temperature.

The hydraulic oil filter (Figure 2-3) is located in the reservoir.

It bolts to the top of the reservoir, and its bypass outlet fits

into a tube welded in the reservoir. The filter housing

contains a replaceable filter element. Returning hydraulic oil

flows through the filter head, through the filter element, and

into the reservoir.

A gauge installed in the filter head indicates how restricted

(clogged) the filter element is. When back pressure caused

by a dirty filter element exceeds 1.70 bar (25 psi), the filter

head’s bypass feature functions to allow the hydraulic oil to

bypass the filter element and flow into the reservoir through

the bypass outlet instead. (Filter changing instructions are in

Return Hydraulic Filter Assembly, page 2-10.)

Pump Distribution

No. 1 Pump

The engine PTO driven pump drive drives the No. 1 pump.

The pump drive converts the PTO shaft’s 2070 rpm at engine

speed of 1800 rpm to 2604 rpm. (The engine speed is limited

to 1800 rpm when operating crane functions; the PTO spins

at 1.15 times the engine speed; the pump drive output shaft

speed is 1.258 times the PTO speed.) The pump drive has a

disconnect to stop power transfer to the No. 1 pump.

Section One of the No. 1 hydraulic pump supplies the hoist,

lift, and telescope directional control valve. The valve

sections control the following functions: main hoist, boom lift,

boom telescope, and, when equipped, auxiliary hoist.

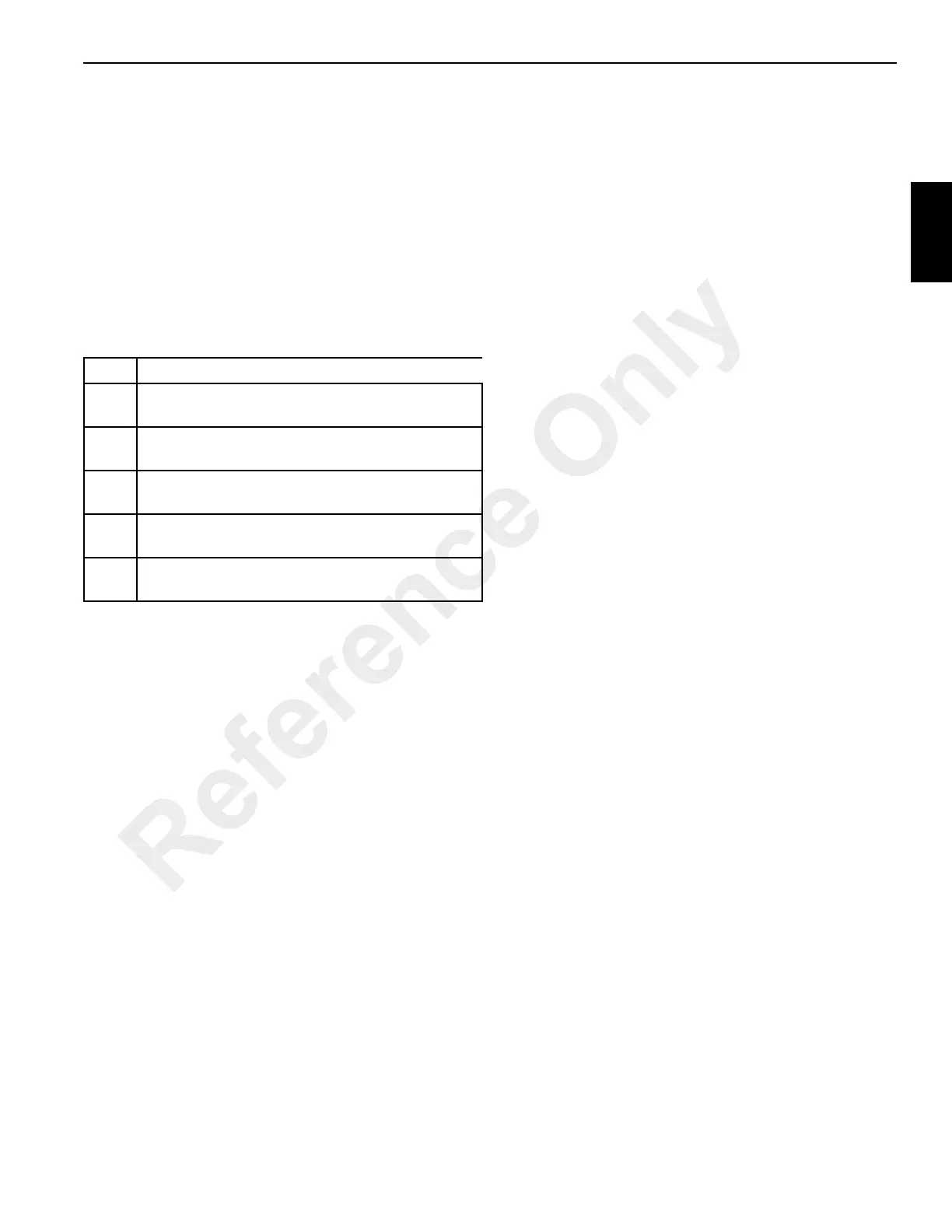

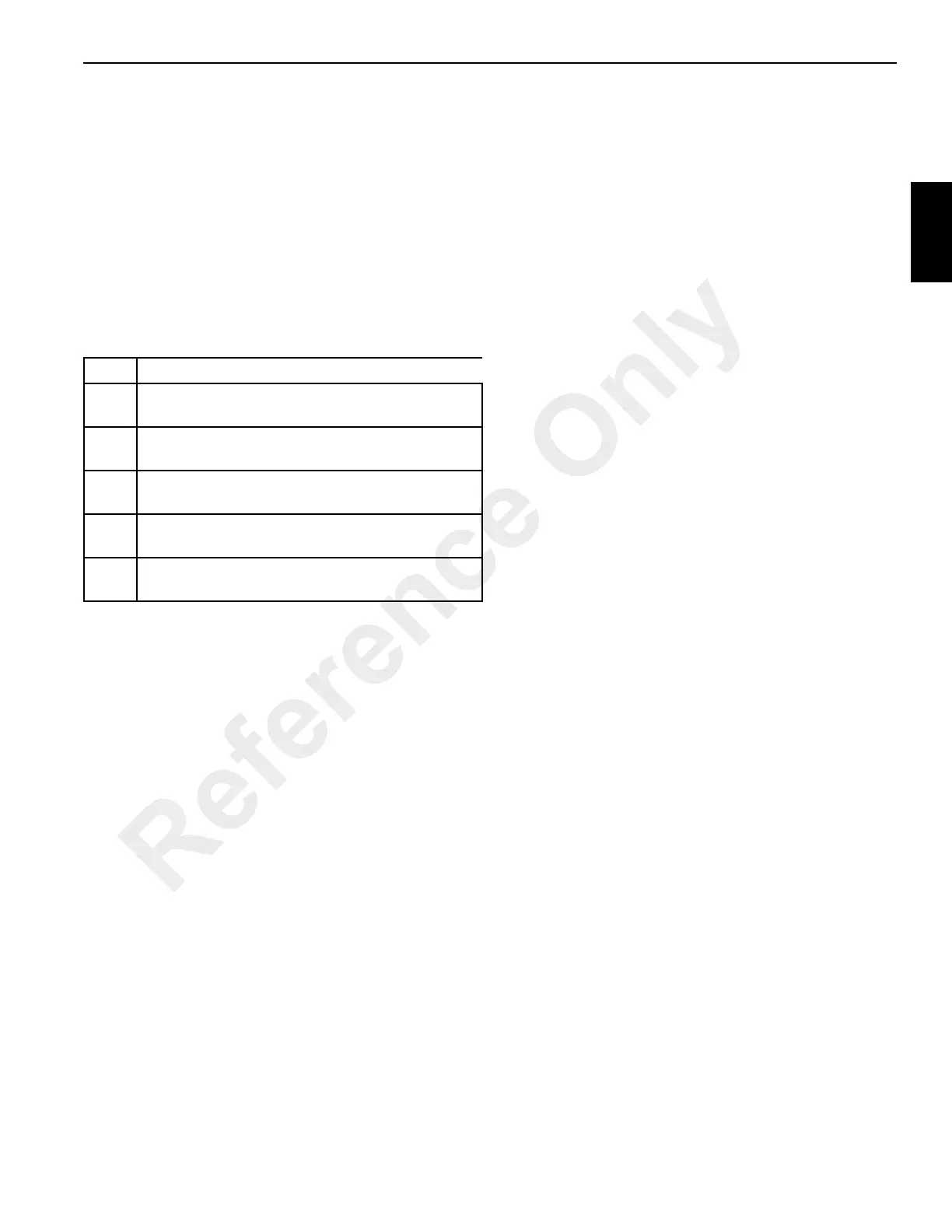

Zone Classification

A

Tropical Moist: All months average above 18°C

(64.4°F). Latitude: 15° - 25 ° North & South

B

Dry or Arid: deficient precipitation most of the year.

Latitude: 20° - 35° North & South

C

Most Mid-Latitude: Temperate with mild winters.

Latitude: 30° - 50° North & South

D

Moist Mid-Latitude: Cold Winters. Latitude: 50° -

70° North & South

E

Polar: Extremely cold winters and summers.

Latitude: 60° - 75° North and South

Reference Only

Loading...

Loading...