Grove Published 01-29-2015, Control # 512-01 2-47

TMS700E SERVICE MANUAL HYDRAULIC SYSTEM

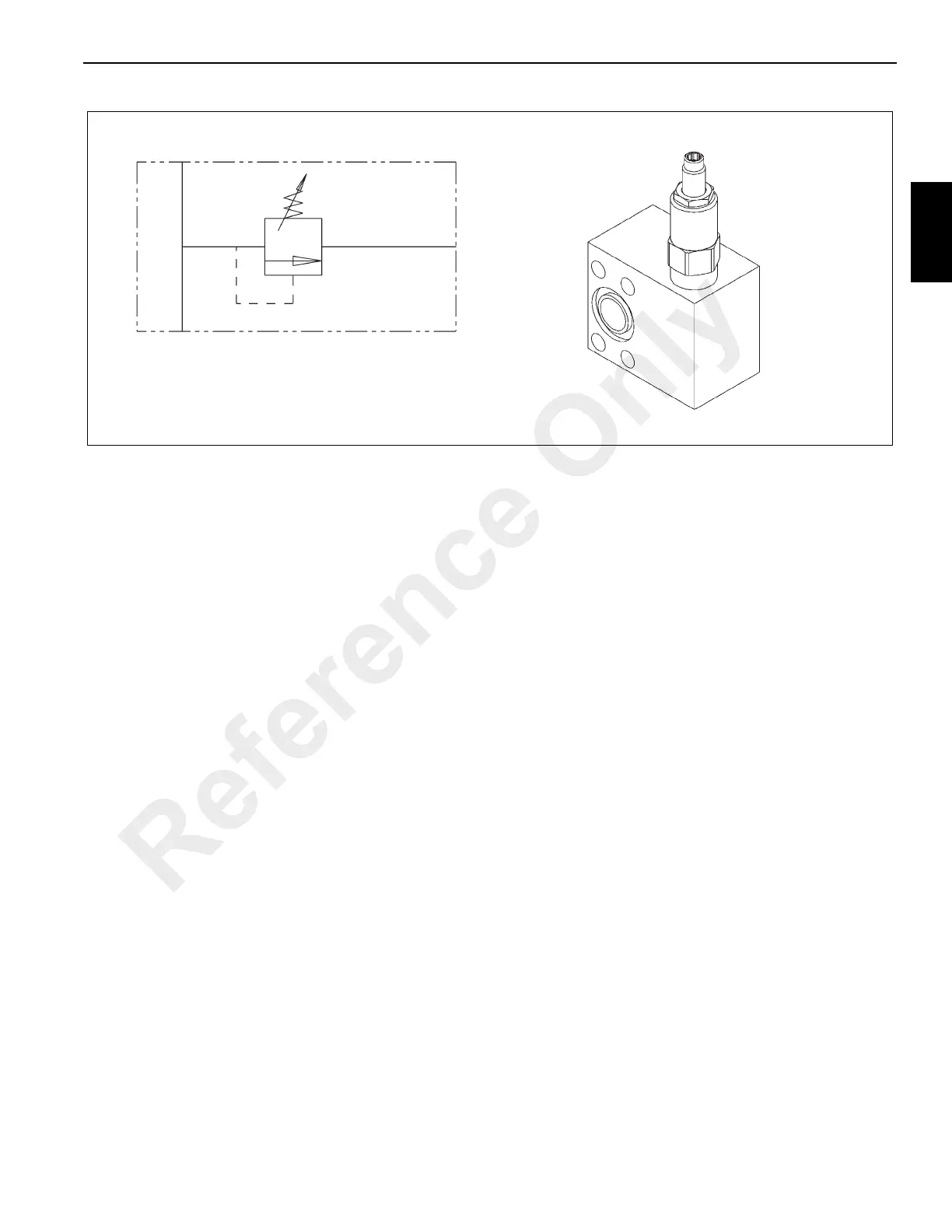

NEEDLE VALVE

Description

The two lift cylinder mounted needle valves are used to

connect the rod and piston sides of the boom lift cylinder

together to allow the boom to float when the boom is in the

trailing boom mode.

The knob adjustable needle valve is installed into a manifold.

Turning the knob counterclockwise opens the valve to allow

the boom flotation and clockwise rotation closes the valve to

return to normal boom lift cylinder operation.

Maintenance

Removal

1. Tag and disconnect the hydraulic lines from the valve

and cap or plug all openings and remove valve.

Installation

1. Connect the hydraulic lines as tagged during removal.

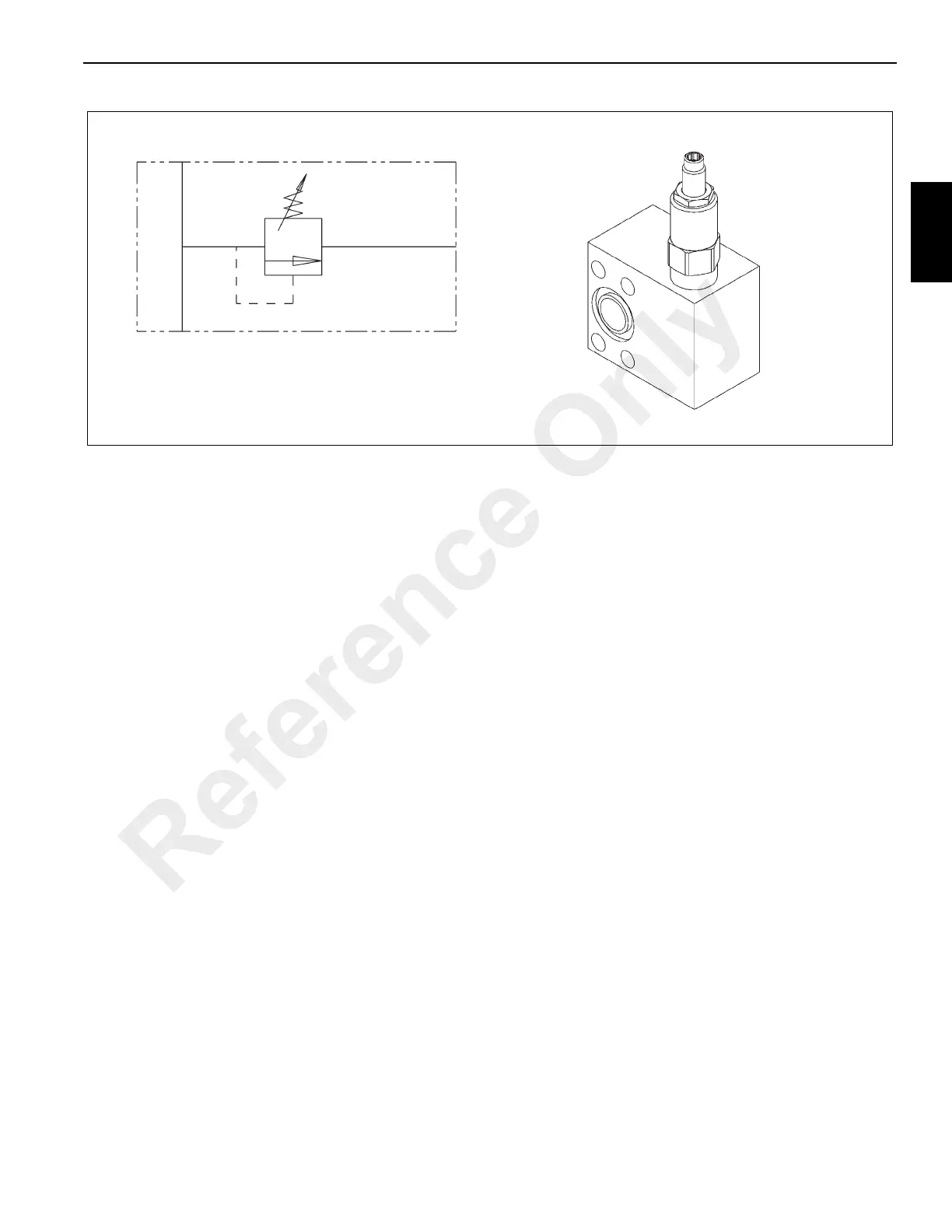

NEEDLE VALVE WITH REVERSE FREE

FLOW CHECK

Description

A needle valve with a reverse free flow check is used to

prevent pressurization of the lift cylinder when the boom lift

cylinder is in the trailing boom mode.

The knob adjustable needle valve and check valve is

installed into a manifold. Turning the knob counterclockwise

opens the valve to allow the normal boom lift operation and

clockwise rotation closes the valve for trailing boom mode.

Maintenance

Removal

1. Tag and disconnect the hydraulic lines from the valve

and cap or plug all openings and remove valve.

Installation

1. Connect the hydraulic lines as tagged during removal.

SWING POWER BRAKE VALVE

Description

The swing power brake valve (Figure 2-35) is used to

provide hydraulic pressure to the piston of the swing brake to

apply the brake. The valve receives its supply of oil from the

main directional control valve pilot generator port.

Depressing the brake pedal causes hydraulic oil to flow to

the top of the brake piston where, combined with spring

tension, the total force overcomes the brake release

pressure and applies the brake. When the valve is released,

excess hydraulic oil flows from the valve to the case drain

manifold and back to the reservoir.

Maintenance

Removal

1. Tag and disconnect hydraulic lines attached to the brake

valve. Cap or plug the lines and ports.

2. Remove the four bolts, lockwashers, flat washers, and

nuts which secure the brake valve to the cab floor.

Remove the brake valve.

6874-2

6874-1

FIGURE 2-34

T1

S

P

Reference Only

Loading...

Loading...