Grove Published 01-29-2015, Control # 512-01 5-9

TMS700E SERVICE MANUAL HOIST AND COUNTERWEIGHT

hardware. Do likewise for the cable guide roller and

shaft and attaching hardware.

2. Inspect each shaft and roller for cracks, scoring, or

grooving. Replace if necessary.

3. Inspect the springs for proper length, tensile strength,

and lack of damage. Replace both springs as a pair if

either is defective.

Assembly

1. Secure the cable guide roller to the two support end

brackets of the hoist with its shaft and attaching

hardware.

2. Secure the cable tension brackets to the two support

end brackets of the hoist with attaching hardware.

3. Secure the cable guard roller to the cable tension

brackets with its shaft and attaching hardware.

4. Attach each of the two springs to its related eyebolt and

jam nut that attach to the spring adjusting bracket on

each of the two support end brackets of the hoist. Attach

the other end of each spring to the spring hole of its

related cable tension bracket.

5. Adjust each spring’s jam nut and eyebolt until there is a

distance of 42 mm (1.7 in) between the jam nut and the

threaded end of the eyebolt.

6. Ensure the cable guide roller can turn, and that it

touches the cable along its cable-touching length.

7. If the cable guard roller’s bearings have grease fittings,

apply EP-MPG grease to them. If the cable guide roller’s

bearings have grease fittings, apply EP-MPG grease to

them.

3

5

3

6

2

4

7

1

3

4

6928-2

6928-1

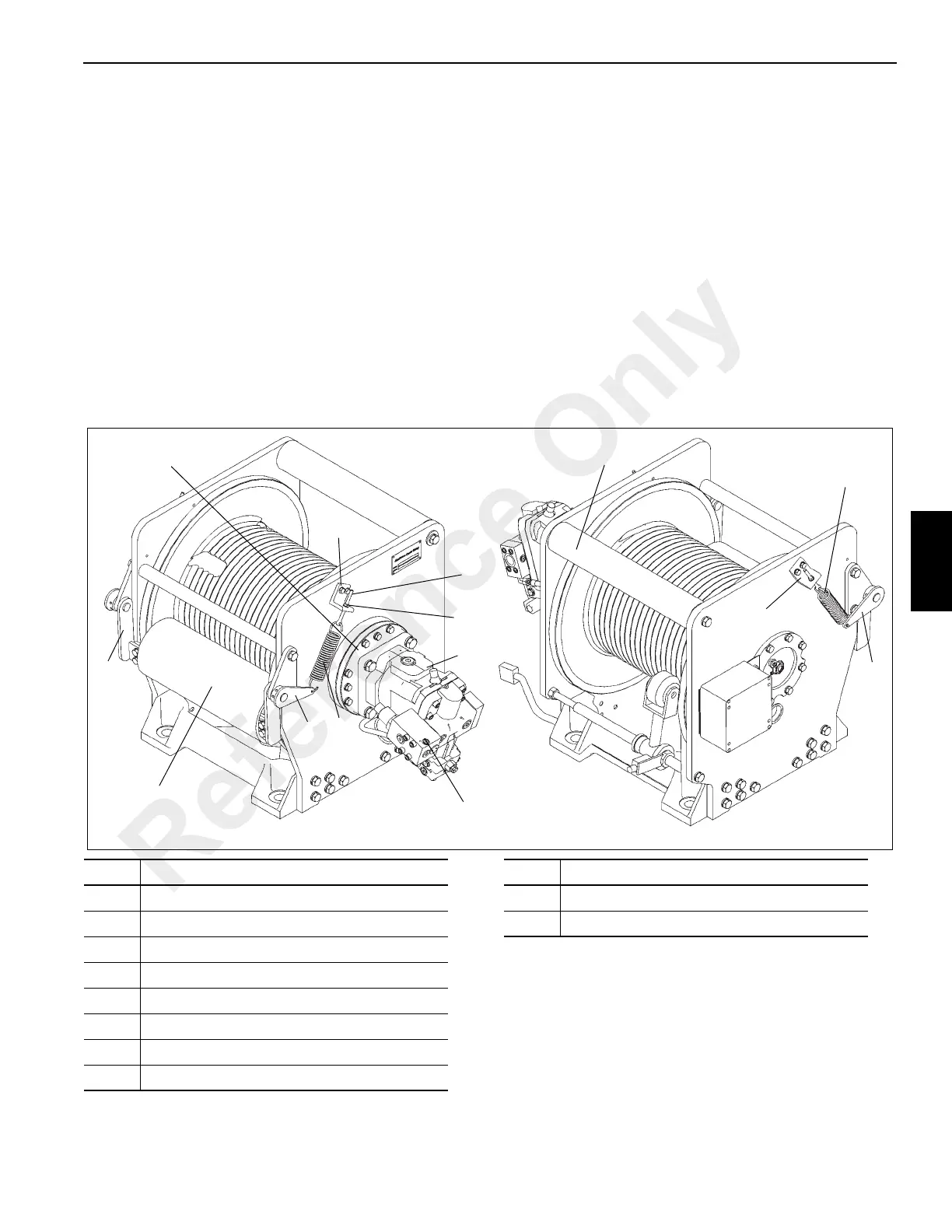

FIGURE 5-4

5

8

9

10

Item Description

1 Cable Guard Roller

2 Cable Guide Roller

3 Cable Tension Bracket

4 Spring Adjusting Bracket

5Spring

6 Eyebolt

7Jam Nut

8Motor

9 Brake Valve

10 Brake Clutch and Brake Cylinder

Item Description

Reference Only