ENGINE

3.33

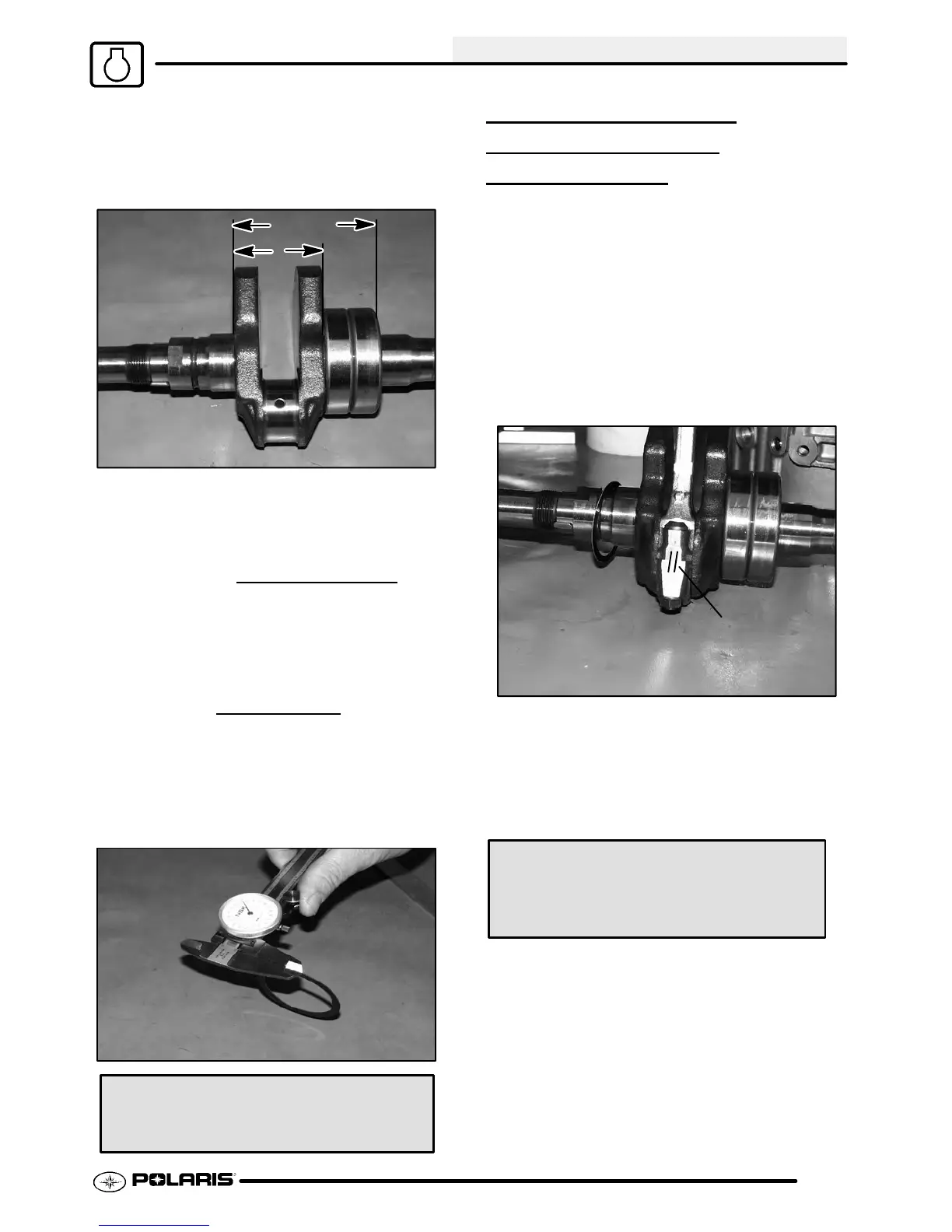

4. Measure the width of the crankshaft at the

bearing seats or, if PTO bearings are installed, the

width from MAG side bearing seat to the outside

race of the PTO bearings with a micrometer or dial

caliper and record.

NOTE: If PTO bearings are not installed,

measure the width of the bearings and add to

crankshaft width.

Crankshaft Width

5. Subtract the Crankshaft Width measured in Step

4 from the Total Case Width recorded in Step 3,

and record below.

Total End Play

6. Subtract the thickness of the existing shim from

the result of Step 5 to determine if a different shim

is required. The result must be within the

specified range listed below. Increase or

decrease shim thickness as required to bring end

play within range.

Crankshaft End Play:

008²-.016² (.02-.04 cm)

ENGINE ASSEMBLY/

CONNECTING

ROD

INSTALLA

TION

1. Clean all oil off connecting rod, connecting rod

cap and bearing inserts.

2. Install bearing inserts onto connecting rod and

cap.

NOTE: First, install bearing tab into groove, then

press the rest of the bearing into place.

3. Apply assembly lube onto the connecting rod

bearings and crank pin.

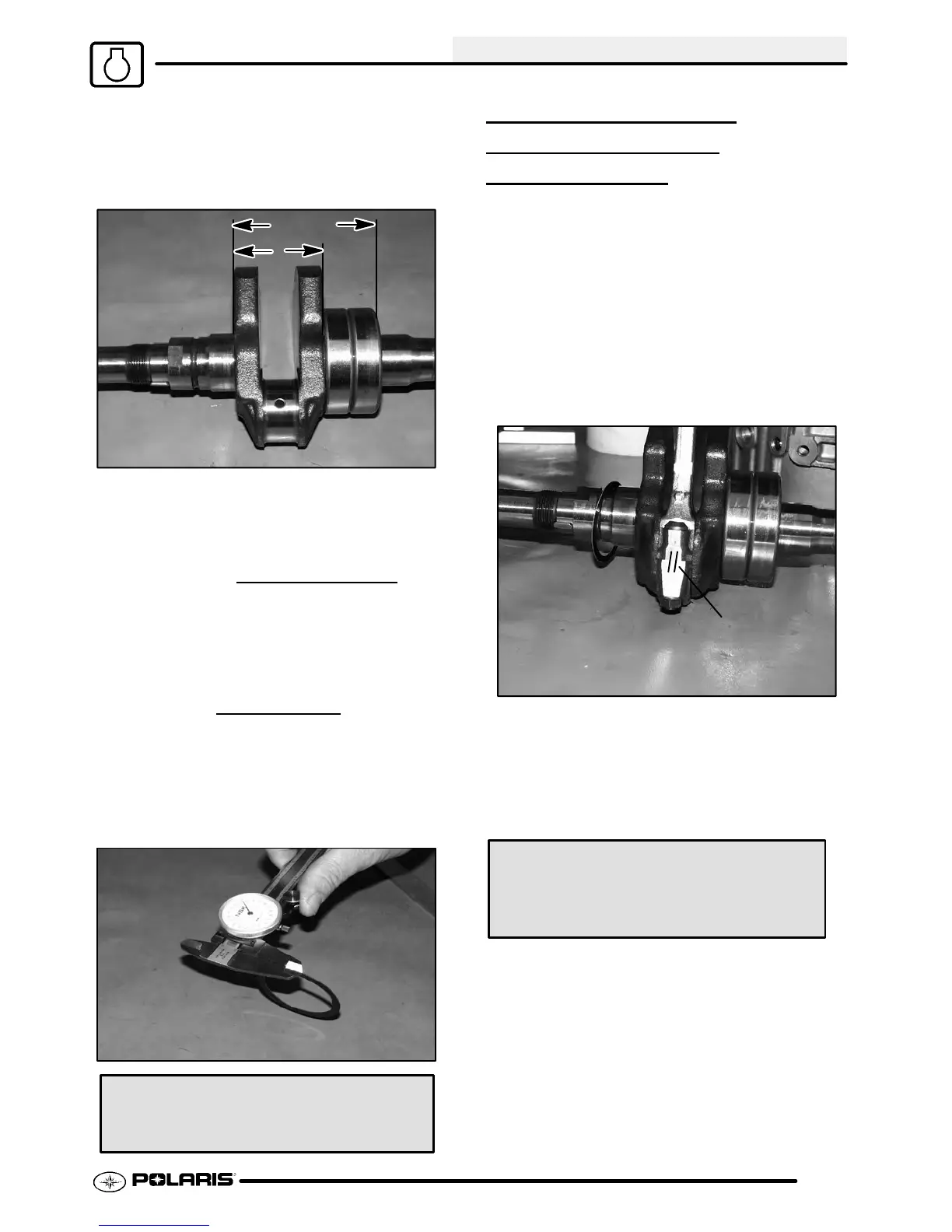

4. Install rod and cap onto the crankshaft. Ensure

that I.D. marks are aligned.

Marks

NOTE: Procedure during disassembly called for

marking of connecting rod and cap. Ensure that each

part is installed in its original location by noting the

marks placed on the parts during disassembly.

5. Tighten rod cap nuts to 1/2 torque specification,

then full torque.

Rod Nut Torque:

29-33 ft. lbs. (39-45 Nm)

6. Verify that the connecting rod is free to rotate on

the crankshaft journal.

Loading...

Loading...